Aluminum Construction Profiles - AA1050 Mill-Finished Aluminum Coils C.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

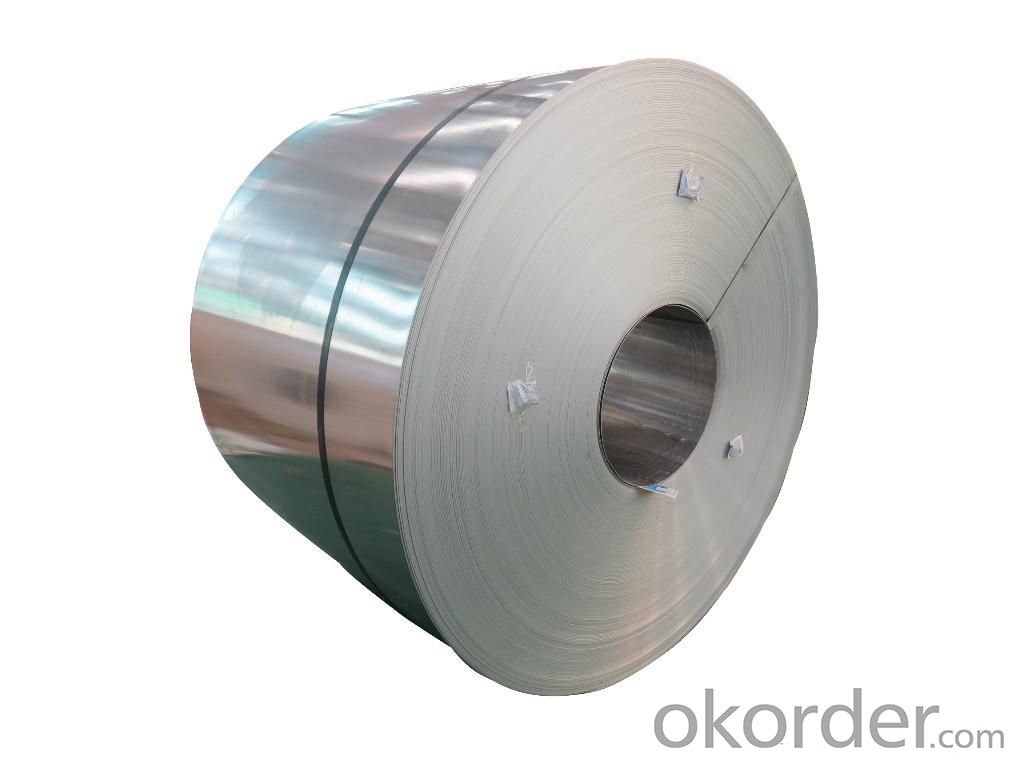

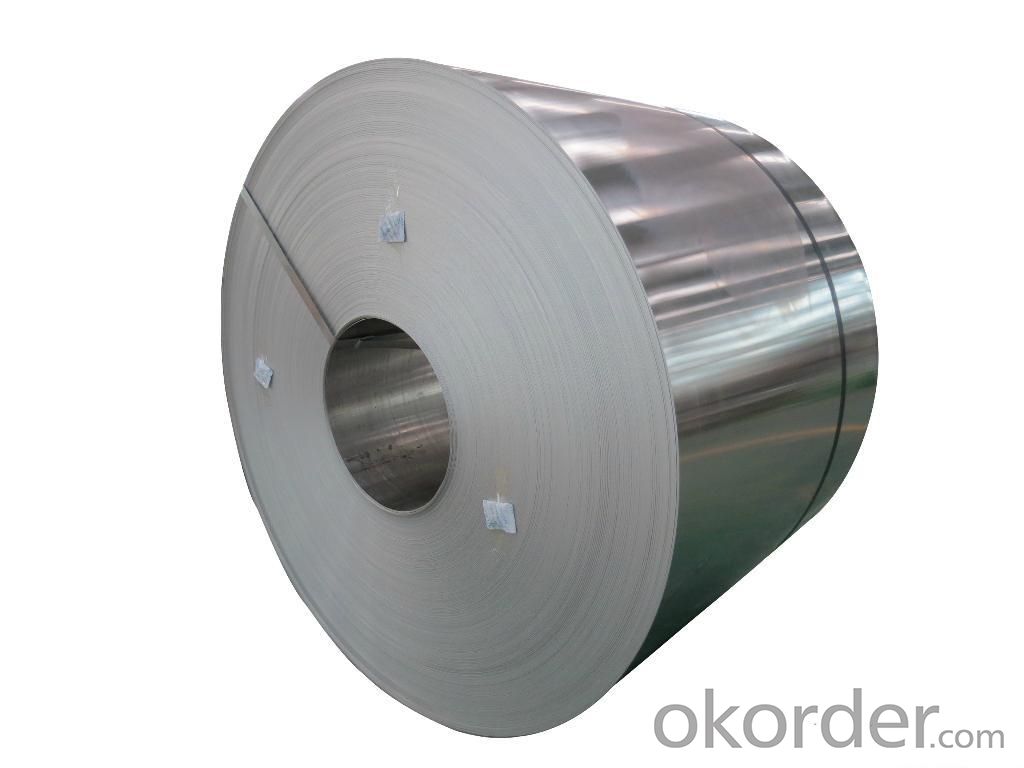

1.Structure of AA1050 Mill-Finished Aluminum Coils C.C Quality Used for Construction Description

AA1050 Mill-Finished Aluminum Coils C.C Quality Used for Construction has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA1050 Mill-Finished Aluminum Coils C.C Quality Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA1050 Mill-Finished Aluminum Coils C.C Quality Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.AA1050 Mill-Finished Aluminum Coils C.C Quality Used for Construction Images

4.AA1050 Mill-Finished Aluminum Coils C.C Quality Used for Construction Specification

Alloy | AA1050 |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA1050 Mill-Finished Aluminum Coils C.C Quality Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA1050 Mill-Finished Aluminum Coils C.C Quality Used for Construction.

B.When will you deliver the products?

It will be delivered within 35 days after receiving original L/C or advanced payment.

- Q: What are the different types of surface protection for aluminum profiles?

- There are several types of surface protection for aluminum profiles, including anodizing, powder coating, painting, and laminating. Anodizing involves creating a durable oxide layer on the surface of the aluminum, providing corrosion and wear resistance. Powder coating involves applying a dry powder to the surface and then curing it with heat, creating a tough and decorative finish. Painting involves applying liquid paint to the surface, providing both protection and aesthetic appeal. Laminating involves applying a layer of protective film or sheet to the surface, offering scratch resistance and added durability.

- Q: What kind of self tapping screw can attack aluminum profile?

- Self tapping screws are used for connecting between thin metal plates. When connecting to the connecting piece for the threaded hole, then tapping screws into the threaded hole of the connecting piece. Because of the self tapping screw thread surface has higher hardness (more than 45HRC), the attack a thread in the threaded hole of the connecting piece, thereby forming a connection.Aluminum material than steel soft, generally in accordance with GB screws can be of aluminum, is recommended to hit bottom hole in the needed position.The following is the national standard for self tapping screws:GB/T15856.1-2002 cross recessed countersunk head tapping screws, material: 20Mn 15MnBGB/T15856.2-2002 cross recessed countersunk head drilling self tapping screw, material: 20Mn 15MnBGB/T15856.3-2002 cross recessed semi countersunk head drilling self tapping screw, material: 20Mn 15MnB

- Q: What are the different surface sandblasting options for aluminum profiles?

- There are several surface sandblasting options for aluminum profiles, including: 1. Aluminum oxide blasting: This involves using aluminum oxide particles to remove surface impurities and create a smooth finish on the aluminum profiles. It is commonly used for cleaning and preparing the surface before further treatments or coatings. 2. Glass bead blasting: Glass beads are used to blast the aluminum surface, which helps to remove oxidation and provide a satin-like finish. This method is often employed for decorative applications or to achieve a specific aesthetic look. 3. Walnut shell blasting: Crushed walnut shells are used as the blasting media to gently remove contaminants and provide a smooth, matte finish on aluminum profiles. It is a non-aggressive option that is suitable for delicate or sensitive surfaces. 4. Steel shot blasting: Steel shot particles are propelled onto the aluminum surface to remove scale, rust, and other imperfections. This method is ideal for heavy-duty cleaning and surface preparation, especially for profiles that will undergo subsequent coatings or treatments. Overall, the choice of sandblasting option for aluminum profiles depends on the desired outcome, surface condition, and the specific requirements of the application.

- Q: Can aluminum profiles be used in solar panel installations?

- Yes, aluminum profiles can be used in solar panel installations. Aluminum is a lightweight and durable material that is commonly used in the construction of solar panel frames. It offers excellent corrosion resistance and can withstand outdoor environmental conditions, making it suitable for long-term use in solar installations. Additionally, aluminum profiles can be easily fabricated and customized to fit specific panel sizes and mounting requirements.

- Q: What are the different surface protection methods for aluminum profiles?

- There are several surface protection methods for aluminum profiles, including anodizing, powder coating, painting, and mechanical finishes. Anodizing is a popular method that creates a protective oxide layer on the surface, providing corrosion resistance and enhancing the appearance. Powder coating involves applying a dry powder onto the profile, which is then cured to create a durable and decorative finish. Painting is another option, where a liquid paint is applied and cured to protect the surface. Mechanical finishes involve processes like brushing or polishing to achieve a desired texture or appearance while still protecting the aluminum profile.

- Q: This question asks for a comparison between aluminum profiles and other materials used in constructing frames, focusing on their characteristics and performance.

- <p>Aluminum profiles are favored for building frames due to their high strength-to-weight ratio, making them lightweight yet durable. They offer excellent corrosion resistance, which is superior to materials like steel, which can rust. Aluminum profiles are also easy to machine and form, allowing for complex designs. Compared to wood, they are more resistant to weathering and pests. However, they may not have the same aesthetic appeal as wood or the thermal insulation properties of some plastics. Overall, aluminum profiles are a strong choice for structural integrity and longevity in frame construction.</p>

- Q: What are the potential health risks associated with handling aluminum profiles?

- <p>Working with aluminum profiles generally does not pose significant health concerns under normal conditions. However, there are a few considerations. Inhalation of aluminum dust can cause respiratory issues, and prolonged exposure may lead to a condition known as 'aluminum dust disease.' Additionally, aluminum can cause skin irritation in some individuals, especially with prolonged contact. It's important to use proper personal protective equipment (PPE), such as masks and gloves, to minimize these risks. Ingestion of aluminum is also a concern, as it can lead to health problems if it enters the body through contaminated food or water, although this is not directly related to handling aluminum profiles.</p>

- Q: This question asks for various methods to enhance the heat transfer efficiency of aluminum profiles.

- <p>Improving the thermal performance of aluminum profiles can be achieved through several methods: 1. Material Selection: Choose aluminum alloys with higher thermal conductivity for better heat transfer. 2. Design Optimization: Design profiles with larger surface areas to increase heat dissipation. 3. Fins and Ribs: Incorporate fins or ribs to increase the surface area and enhance heat dissipation. 4. Coating: Apply thermally conductive coatings to improve heat transfer. 5. Insulation: Use thermal insulation to reduce heat loss. 6. Heat Sinks: Integrate heat sinks to dissipate heat more effectively. 7. Composite Materials: Combine aluminum with other materials to improve thermal properties. 8. Manufacturing Techniques: Employ advanced manufacturing techniques to create more efficient profiles. Each method can be tailored to specific applications to achieve optimal thermal performance.</p>

- Q: Can aluminum profiles be used in telecommunications infrastructure?

- Yes, aluminum profiles can be used in telecommunications infrastructure. Aluminum is a lightweight and durable material that offers excellent structural integrity and corrosion resistance, making it suitable for various applications within telecommunications infrastructure, such as antenna towers, cable trays, and equipment racks. Additionally, aluminum profiles can be easily customized and fabricated to meet specific requirements, making them a versatile choice for telecom installations.

- Q: What do the 6063 and T5 represent in the aluminum profile 6063-T5?

- third, and four digits:Pure aluminum: represents the original alloyAlloy: the designation of individual alloys"- >: the back of Hn or Tn indicates the condition of work hardening or the symbol of heat treatment state-Hn: indicating the symbol for non heat treated alloys-Tn: a symbol for heat treatment alloysT5By cooling the high temperature molding process, and then the artificial aging state. Applied by cooling high temperature molding process, not through the cold processing (for straightening and leveling, but does not affect the mechanical properties of the limit), to artificial aging products.

Send your message to us

Aluminum Construction Profiles - AA1050 Mill-Finished Aluminum Coils C.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords