Aluminum Profiles for Glass - Industrial Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

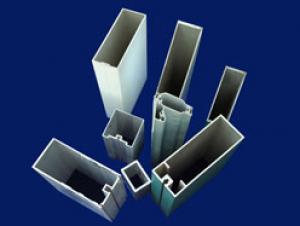

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: What are the different surface treatments for aluminum profiles?

- There are several different surface treatments available for aluminum profiles, each offering unique benefits and characteristics. Some of the most common surface treatments for aluminum profiles include anodizing, powder coating, painting, and brushing. Anodizing is a popular surface treatment method that involves creating a protective oxide layer on the aluminum surface. This process enhances the corrosion resistance of the aluminum, making it suitable for outdoor applications. Anodized aluminum profiles are also known for their aesthetic appeal, as they can be dyed in various colors for a sleek and modern finish. Powder coating is another widely used surface treatment technique for aluminum profiles. It involves applying a dry powder paint onto the aluminum surface, which is then cured under heat to create a durable coating. Powder-coated aluminum profiles offer excellent resistance to scratching, chipping, and fading, making them ideal for applications that require long-lasting and vibrant finishes. Painting is a versatile surface treatment option that allows for a wide range of color choices and finishes. Aluminum profiles can be painted using various methods, such as spray painting or electrostatic coating. Painted aluminum profiles provide a smooth and attractive appearance, suitable for both indoor and outdoor applications. Brushing is a surface treatment technique that involves brushing the aluminum surface with a wire brush or abrasive material. This process creates a textured finish, giving the aluminum a distinctive and decorative look. Brushed aluminum profiles are often chosen for architectural and design applications that require a unique and stylish appearance. Overall, the choice of surface treatment for aluminum profiles depends on the specific requirements of the application. Factors such as corrosion resistance, durability, aesthetic appeal, and functionality play a crucial role in determining the most suitable surface treatment method for aluminum profiles.

- Q: What are the different shapes and sizes of aluminum profiles available?

- A diverse selection of shapes and sizes of aluminum profiles are accessible to accommodate different industrial and architectural needs. Some frequently encountered shapes of aluminum profiles comprise: 1. T-shape: These profiles possess a T-shaped cross-section, consisting of a horizontal top and a vertical stem. They are commonly utilized in framing and structural applications. 2. U-shape: U-shaped profiles exhibit a U-shaped cross-section, featuring two parallel horizontal arms and a connecting vertical stem. They are often employed as edge trims or decorative moldings. 3. L-shape: L-shaped profiles display a right-angle cross-section, with one arm longer than the other. They are frequently used as brackets or corner guards. 4. Square: Square profiles exhibit equivalent width and depth, resulting in a square-shaped cross-section. They offer versatility and can be applied for various purposes, such as frames, supports, or enclosures. 5. Rectangular: Rectangular profiles possess unequal width and depth, forming a rectangular cross-section. They are commonly utilized for structural intentions, like beams or frames. 6. Round: Round profiles showcase a circular cross-section and are commonly employed for applications necessitating a curved or smooth finish, such as handrails or decorative elements. Furthermore, aluminum profiles are obtainable in an assortment of sizes, ranging from diminutive dimensions suitable for lightweight applications to larger sizes for heavy-duty usage. The measurements of aluminum profiles are determined by their width, depth, and thickness, which can be personalized based on specific project requirements. In summary, the broad range of shapes and sizes of aluminum profiles allows for adaptability and versatility in design and construction, ensuring the availability of an appropriate profile for every application.

- Q: How do you calculate the weight-bearing capacity of aluminum profiles?

- The weight-bearing capacity of aluminum profiles can be calculated by considering various factors such as the dimensions and shape of the profile, the alloy and temper of the aluminum, and the applied load conditions. This calculation typically involves analyzing the cross-sectional properties of the profile, including moment of inertia and section modulus, and comparing them with the expected load requirements. It is important to consult relevant engineering standards and guidelines or seek professional advice to ensure accurate and safe calculations.

- Q: Shenzhen aluminum profile manufacturers which good?

- For the choice of aluminum profiles, here are a few suggestions for you to refer to:First: very cheap, do not chooseAs follows: the cost of industrial aluminum material = the spot price of aluminum ingot, the processing cost of extrusion aluminum material, the freight of packing material. These are transparent, the cost of aluminum profiles are similar, significantly lower than the market price, the first possibility: the weight per meter less; second: aluminum is the use of recycled materials; third: material loss amplification (not according to the actual sales amount of meters).Second: only understand the sale material supplier does not choose

- Q: What are the different powder coating options for aluminum profiles?

- Aluminum profiles offer a variety of powder coating options, each with its own advantages and characteristics. Let's explore the different choices: 1. Polyester powder coating: This option is both common and cost-effective for aluminum profiles. It provides great UV resistance and color retention, making it suitable for indoor and outdoor use. You can choose from a wide range of colors and finishes, including matte, glossy, and textured. 2. Epoxy powder coating: If you need strong adhesion and corrosion resistance, epoxy coatings are the way to go. They are perfect for demanding environments like marine or industrial applications. Additionally, they have good chemical resistance and are often used as a primer before applying a topcoat for extra durability. 3. Polyurethane powder coating: When durability and abrasion resistance are essential, polyurethane coatings excel. They are ideal for high-traffic areas or surfaces prone to wear and tear. With excellent color retention and gloss retention, you can expect a long-lasting finish. 4. Fluoropolymer powder coating: Known for their exceptional resistance to chemicals, UV radiation, and weathering, fluoropolymer coatings, such as PVDF (polyvinylidene fluoride), are highly durable. They provide excellent color retention, making them suitable for architectural applications where long-term performance is crucial. 5. Hybrid powder coating: If you're looking for a balanced option that combines the benefits of epoxy and polyester resins, hybrid coatings are your answer. They offer excellent adhesion and color retention, along with good weather resistance. Hybrid coatings are often used in general-purpose applications where cost-effectiveness is a priority. Remember to consider the specific requirements of your project when choosing a powder coating option for aluminum profiles. Factors like intended use, environmental conditions, and desired aesthetics will help determine the most suitable option to achieve the desired performance and appearance.

- Q: Can aluminum profiles be used in warehouse and storage systems?

- Yes, aluminum profiles can be used in warehouse and storage systems. Aluminum profiles are lightweight, durable, and corrosion-resistant, making them suitable for various applications in warehouses and storage systems. They can be used to construct shelving units, racks, and partitions to optimize storage space and organize inventory. Aluminum profiles are also known for their versatility, as they can be easily customized and assembled to meet specific storage requirements. Additionally, aluminum profiles offer excellent strength-to-weight ratio, allowing them to support heavy loads without compromising structural integrity. Overall, aluminum profiles are a popular choice in warehouse and storage systems due to their durability, flexibility, and cost-effectiveness.

- Q: How to calculate the spraying powder of aluminium profile?

- Ask not detailed, do not know what you want to ask is how?

- Q: This question asks for guidance on selecting suitable aluminum profiles for a construction project.

- <p>To choose the right aluminum profiles for your building project, consider the following: 1. Load-bearing capacity: Select profiles that can withstand the weight and stress of your structure. 2. Application: Choose profiles suitable for the specific application, such as window frames, curtain walls, or support beams. 3. Aesthetics: Opt for profiles that match your project's design and architectural style. 4. Durability: Look for high-quality aluminum with good corrosion resistance and weather resistance. 5. Cost: Compare prices and choose profiles that offer the best value for money. 6. Supplier reputation: Work with reputable suppliers known for quality products and reliable service. Consult with engineers or architects to ensure you select the most appropriate profiles for your project's needs.</p>

- Q: Are aluminum profiles suitable for use in exterior wall insulation systems?

- <p>Yes, aluminum profiles can be used for exterior wall insulation systems. They are known for their durability, resistance to corrosion, and ability to withstand various weather conditions. Aluminum profiles provide a strong structural framework that can support insulation materials effectively. They are also lightweight, which makes them easy to handle and install. Additionally, aluminum profiles can be anodized or coated to enhance their resistance to environmental factors, making them a popular choice for exterior insulation systems.</p>

- Q: Where is the exact location? TwentyBecause I was doing aluminum sales, want to go to the market!Where is the specific market aluminum sales, as long as there is, I have to go around! Say where it is! For example, what area, what road, how many?! Since I went to Chengdu for the first time, please tell me more about it. Thank you!

- Two days ago in the city to find the north gate, Xinshengda profile market have taken a little more, Sammy, the gold house electrical city only one sell Aluminum Alloy, Wanguan electrical didn't go to see, tailor steel city to ask a security guard said little or no 512, no Aluminum Alloy sold, only 512 of the next street there is a Aluminum Alloy sell (416 opposite the hospital). Today I went to Qingbaijiang Fengxiang profile market. Where is the place where the aluminum alloy merchants gathered, the profiles, accessories, processing?...... Goods are available in all varieties。 But the aluminum doors and windows only home balcony with the majority, profile industry, such as steel rack chassis radiator with basically No. This market sells stainless steel materials, businesses are also more. Bus route Liang Jia lane to Qingbaijiang on the car, told the driver to Fengxiang market under the line, and 6 yuan fare, cheaper! Drive away the State Road 108 to Mi Mou Town, Fengxiang market in 108 State Road next great, far away saw. This is the latest information, 2013-9-12

Send your message to us

Aluminum Profiles for Glass - Industrial Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords