T Slot Extruded Aluminum Profiles - High Quality 6000 Series for Industrial Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

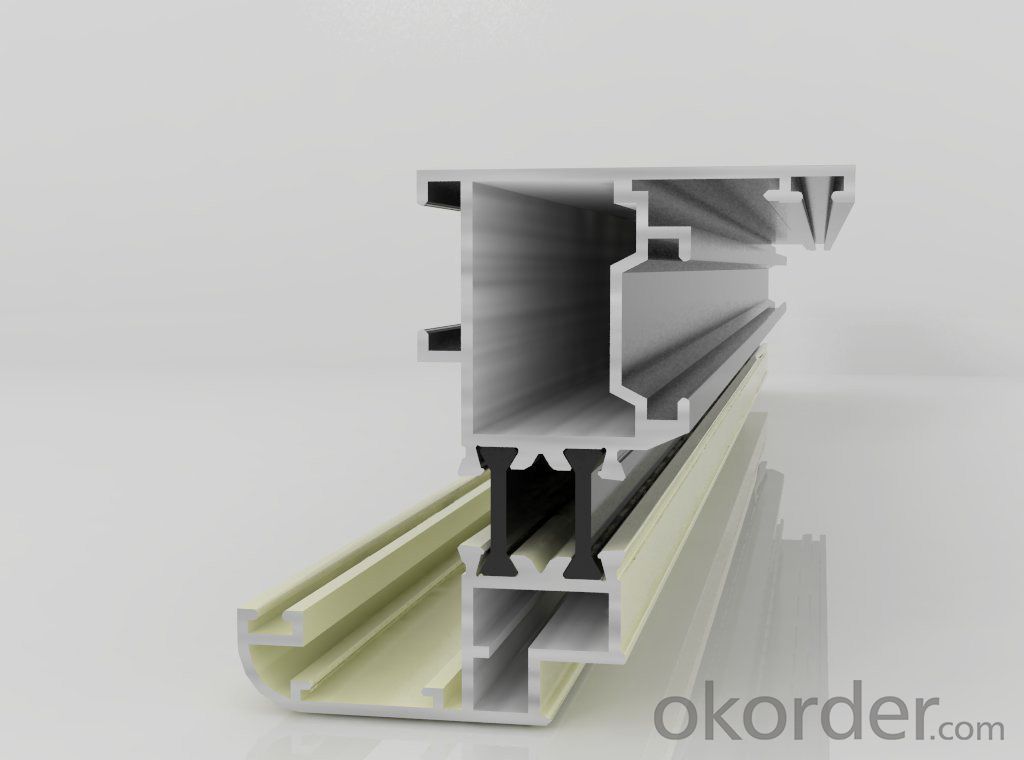

Structure of Aluminum Profile High Quality 6000 Series For Industrial Usages Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminum Profile High Quality 6000 Series For Industrial Usages:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

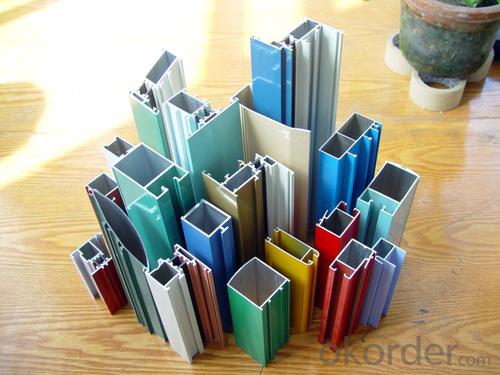

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

Images of the Aluminum Profile High Quality 6000 Series For Industrial Usages:

Aluminum Profile High Quality 6000 Series For Industrial Usages Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: Can aluminum profiles be used for framing mirrors?

- Yes, aluminum profiles can be used for framing mirrors. Aluminum is a lightweight and durable material that can provide a sleek and modern look to mirror frames. It is also resistant to corrosion, making it suitable for use in bathrooms or other areas with high humidity. Additionally, aluminum profiles can be easily customized and come in various finishes, allowing for flexibility in design.

- Q: Can aluminum profiles be used for creating protective enclosures?

- Indeed, protective enclosures can be fashioned using aluminum profiles. Aluminum, being a lightweight, long-lasting, and corrosion-resistant substance, proves itself fitting for a plethora of purposes, including protective enclosures. By effortlessly fabricating and assembling aluminum profiles, one can generate tailored enclosures of diverse dimensions and forms. They grant exceptional structural integrity and endure even the harshest environmental circumstances. Furthermore, in the event that efficient heat dispersal is necessary, aluminum profiles present commendable thermal conductivity. All in all, the versatility, strength, and durability of aluminum profiles render them a favored choice for the creation of protective enclosures.

- Q: This question asks whether aluminum profiles can be utilized to minimize heat loss or gain within buildings.

- <p>Yes, aluminum profiles can be used to reduce heat loss or gain in buildings. They are often used in combination with thermal break technology, which prevents heat transfer across the aluminum frame. This technology can significantly improve a building's energy efficiency by reducing heat conduction through the frame. Additionally, aluminum profiles can be used in the construction of energy-efficient windows and doors, further enhancing insulation and reducing heat transfer. The lightweight and durable nature of aluminum also makes it an attractive material for sustainable building practices.</p>

- Q: What are the fire safety regulations for aluminum profiles?

- The fire safety regulations for aluminum profiles vary depending on the specific application and building codes in each jurisdiction. However, in general, aluminum profiles used in construction must meet certain fire resistance standards to ensure safety. This may include factors such as the thickness and composition of the aluminum, the use of fire-resistant coatings or insulation, and compliance with international fire safety standards like ASTM E119 or EN 13501. It is important to consult local building codes and regulations to determine the specific fire safety requirements for aluminum profiles in a particular area.

- Q: What are the different surface treatment options available for aluminum profiles?

- Some of the different surface treatment options available for aluminum profiles include anodizing, powder coating, painting, polishing, and brushing.

- Q: Are aluminum profiles suitable for mass production or large-scale projects?

- Yes, aluminum profiles are highly suitable for mass production or large-scale projects. Aluminum is a lightweight and durable material that offers numerous advantages for industrial use. Its strength-to-weight ratio is excellent, allowing for the creation of lightweight but robust structures. This makes it easier to transport and assemble large-scale projects while maintaining structural integrity. Aluminum profiles can be easily extruded into various shapes and sizes, providing flexibility in design and accommodating different project requirements. The extrusion process is highly efficient, making it cost-effective for mass production. Additionally, aluminum is a highly recyclable material, making it environmentally friendly and sustainable for large-scale projects. Moreover, aluminum profiles offer excellent corrosion resistance, which is crucial for projects in outdoor or harsh environments. They can withstand extreme temperatures, UV radiation, and moisture, ensuring long-term durability and reducing maintenance costs. The versatility of aluminum profiles also allows for easy integration with other materials, such as glass or composite panels, enhancing the aesthetic appeal and functionality of the final product. Overall, the versatility, strength, lightweight nature, cost-effectiveness, and environmental sustainability of aluminum profiles make them an ideal choice for mass production or large-scale projects.

- Q: Can aluminum profiles be utilized in high-rise constructions that incorporate large windows?

- <p>Yes, aluminum profiles are commonly used in high-rise buildings with large windows due to their strength, durability, and lightweight properties. They offer excellent resistance to corrosion and weathering, making them ideal for external applications. Additionally, aluminum profiles can be easily customized to fit various window designs and sizes, providing both aesthetic and functional benefits. Their thermal break technology also helps in reducing heat transfer, enhancing energy efficiency in buildings.</p>

- Q: Are aluminum profiles suitable for outdoor sign applications?

- <p>Yes, aluminum profiles are commonly used for outdoor signage due to their durability, resistance to corrosion, and lightweight properties. They can withstand various weather conditions without rusting or fading, making them an ideal material for long-lasting outdoor signs. Aluminum profiles can be easily cut, shaped, and assembled, offering flexibility in design and functionality.</p>

- Q: Can aluminum profiles be used for creating lightweight furniture?

- Indeed, lightweight furniture can be fashioned using aluminum profiles. Given its lightweight and durable nature, aluminum proves to be an optimal choice for furniture design when weight is a factor to be taken into account. The malleability of aluminum profiles allows for their transformation into an assortment of furniture elements, including frames, legs, and supports. Moreover, the corrosion resistance offered by aluminum profiles is highly advantageous for furniture intended for outdoor or moisture-exposed environments. The adaptability of aluminum profiles enables the conception of elegant and contemporary furniture designs that not only possess a feather-light quality but also possess an aesthetically appealing allure.

- Q: This question asks if aluminum profiles can be utilized in the construction of environmentally friendly buildings.

- <p>Yes, aluminum profiles can be used for green building applications. They are valued for their durability, recyclability, and energy efficiency. Aluminum is lightweight, which reduces the building's carbon footprint during transportation. It also has excellent thermal conductivity, allowing for better insulation and energy conservation. Additionally, aluminum can be recycled without losing its properties, contributing to a circular economy and reducing waste. These characteristics make aluminum profiles suitable for sustainable construction practices.</p>

Send your message to us

T Slot Extruded Aluminum Profiles - High Quality 6000 Series for Industrial Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords