Aluminum Perforated Metal Sheets - Aluminium Coils AA1060 for Manufacturing Coated Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

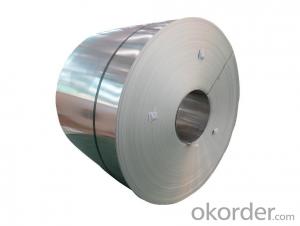

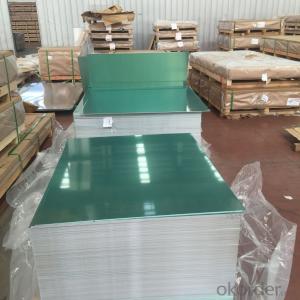

1.Structure of Aluminium Coils AA1060 for Manufacturing Coated Coils Description

The aluminum content of Aluminium Coils AA1060 for Manufacturing Coated Coils is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminium Coils AA1060 for Manufacturing Coated Coils is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of the Aluminium Coils AA1060 for Manufacturing Coated Coils

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.Aluminium Coils AA1060 for Manufacturing Coated Coils Images

4.Aluminium Coils AA1060 for Manufacturing Coated Coils Specification

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc. |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminium Coils AA1060 for Manufacturing Coated Coils

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminium Coils AA1060 for Manufacturing Coated Coils products.

B.When will you deliver the products?

Aluminium Coils AA1060 for Manufacturing Coated Coils will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: What is the lifespan of an aluminum sheet?

- The lifespan of an aluminum sheet can vary depending on various factors such as the grade of aluminum, the thickness of the sheet, the environment it is exposed to, and the level of maintenance it receives. Generally, aluminum sheets are known for their durability and long lifespan. Aluminum is a corrosion-resistant metal, meaning it can withstand exposure to moisture and other environmental elements without deteriorating as quickly as other materials. This makes aluminum sheets highly resistant to rust and corrosion, which can significantly extend their lifespan. In general, aluminum sheets can last anywhere from 20 to 50 years or even longer. However, it is important to note that this estimate may change based on the specific application and conditions the sheet is subjected to. For example, aluminum sheets used in outdoor applications, such as roofing or siding, may have a shorter lifespan due to exposure to harsh weather conditions such as UV radiation, extreme temperatures, and heavy rainfall. To maximize the lifespan of an aluminum sheet, proper maintenance and care are crucial. This includes regular cleaning to remove any dirt or debris that can accumulate and potentially cause damage. Additionally, applying protective coatings or treatments can further enhance the sheet's resistance to corrosion and extend its lifespan. Overall, when properly maintained and used in the appropriate applications, aluminum sheets can have a long lifespan, making them a reliable and cost-effective choice for various industries and purposes.

- Q: My professor gave us the following:1roll of Reynonlds Wrap Heavy Duty Aluminum18.0 in wide, 500.0 ft long and 0.94mil thickThe cost $48.98and I'm not sure how to figure it out

- length * width * thickness = volume (with some unit conversions) Mass = volume * density (look up the density of aluminum) convert mass to moles. convert moles to atoms Divide the cost by the number of Al atoms.

- Q: Can 101 aluminum sheets be bent without cracking or breaking?

- No, it is highly unlikely that 101 aluminum sheets can be bent without cracking or breaking.

- Q: Are aluminum sheets suitable for elevator interiors?

- Yes, aluminum sheets are suitable for elevator interiors. Aluminum is a durable and lightweight material that is resistant to corrosion, making it ideal for use in elevator interiors. It can be easily customized and offers a sleek and modern aesthetic. Additionally, aluminum is easy to clean and maintain, making it a practical choice for elevator interiors.

- Q: Can someone explain the movement of electrons in a pure block of aluminum metal? At they free to move around between similar energy levels? Are they bound to Al atoms? What about orbital overlap?

- Any element that allows the transfer of electrical flow to move across it usually has the characteristic of having free movement electrons in the outer shell. This is why metals are particularly good at electrical conduction. The best metal for transferring electrical charge is silver followed by copper and then aluminum. Much electrical wire is made from pure aluminum because it is cheaper than copper or silver and the resistance to flow is only slightly lower than copper. The electrons in the outer shells are still bound to the aluminum nucleus but they are free to accept a charge from neighboring aluminum atoms and transfer that charge to the next aluminum in the electrical flow. This is basically the definition of electrical resistance. Copper performs this transfer more efficiently than aluminum so it's electrical resistivity is less than aluminums. But in both base metals, the outer electrons never leave the atom, they simply transfer their charge to the next atom in line

- Q: which has greater density 5 kg of lead or 10 kg of aluminum

- The density of ANY amount of lead is greater than the density of ANY amount of aluminum. So even if we have a tiny speck of lead, and a truckload of Aluminum the lead still has greater density. The density of a substance does not depend on how much of it we have. One drop of water have a density of 1g/cm^3 and an ocean of water have exactly the same density of 1g/cm^3. The only difference is that the drop of water has less mass than the ocean, hence it would be easier to fetch; and the drop also has less volume hence it takes up less space.

- Q: How is the thickness of an aluminum sheet measured?

- The thickness of an aluminum sheet is typically measured using a tool called a micrometer. This handheld device applies pressure to the sheet and displays the measurement in millimeters or inches on a digital or analog gauge.

- Q: When water continually sprays on the aluminum sheet, how to avoid corrosion of aluminum sheet and keep its water resistance?

- Don’t worry about it, after aluminum contacts water or air, a layer of oxide film will generate on its surface to separate aluminum from the water or air and protect it, so it won’t be erosive.

- Q: I have seen some stainless steel rifles that you can basically dunk in water, require no cleaning, etc and perform time after time. If SS is so good why are most weapons made of aluminum parts which is then anodized coated black? If you dunk these weapons in water will they rust? Thanks

- The components of guns that have to deal with the heaviest forces and pressures (receivers, barrels, bolts) are almost always some form of steel, not aluminum. Stainless steels are MORE EXPENSIVE, consequently other equally strong but less expensive steels is used and coated with a protective finish, like bluing or parkerization (steel cannot be anodized). Sometimes steel is chromed or nickel coated to look like stainless steel. Aluminum is used in frames and lower receivers and possibly other smaller parts, and in fact aluminum is actually MORE corrosion resistant than stainless steel. Generally the alternative material to aluminum these days is some form of polymer. For example, while sig sauer uses aluminum frames on their handguns, Glock uses polymer frames. Stainless steel used in guns will rust if you don't take care of it. Blued, parkerized, and other protective finished steels will not rust under most conditions if they are taken care of. Otherwise all the armies of the world would have very rusty guns.

- Q: What is the density of 101 aluminum sheets?

- The thickness and dimensions of each sheet are factors that affect the density of 101 aluminum sheets. Typically, aluminum has a density of approximately 2.7 grams per cubic centimeter (g/cm³). To determine the density of the 101 aluminum sheets, one must have knowledge of the mass and volume of each individual sheet. By dividing the cumulative mass of the sheets by their combined volume, the density can be ascertained.

Send your message to us

Aluminum Perforated Metal Sheets - Aluminium Coils AA1060 for Manufacturing Coated Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords