Welding Aluminum Sheets - AA1XXX Coated Aluminum Coils for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA1xxx Coated Aluminum Coils Used for Construction Description

AA1xxx Coated Aluminum Coils Used for Construction are of a wide range of colors, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

AA1xxx Coated Aluminum Coils Used for Construction have been widely used in the fields of construction and decoration, electronic applications, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

2.Main Features of AA1xxx Coated Aluminum Coils Used for Construction

1)Excellent weather-proof durability

2)Anti-ultraviolet

3)High erosion resistance

4)Stable color and gloss

5)Good mechanical processing performance

6)Abrasion resistance

7)Anti-impact

8)High flexibility

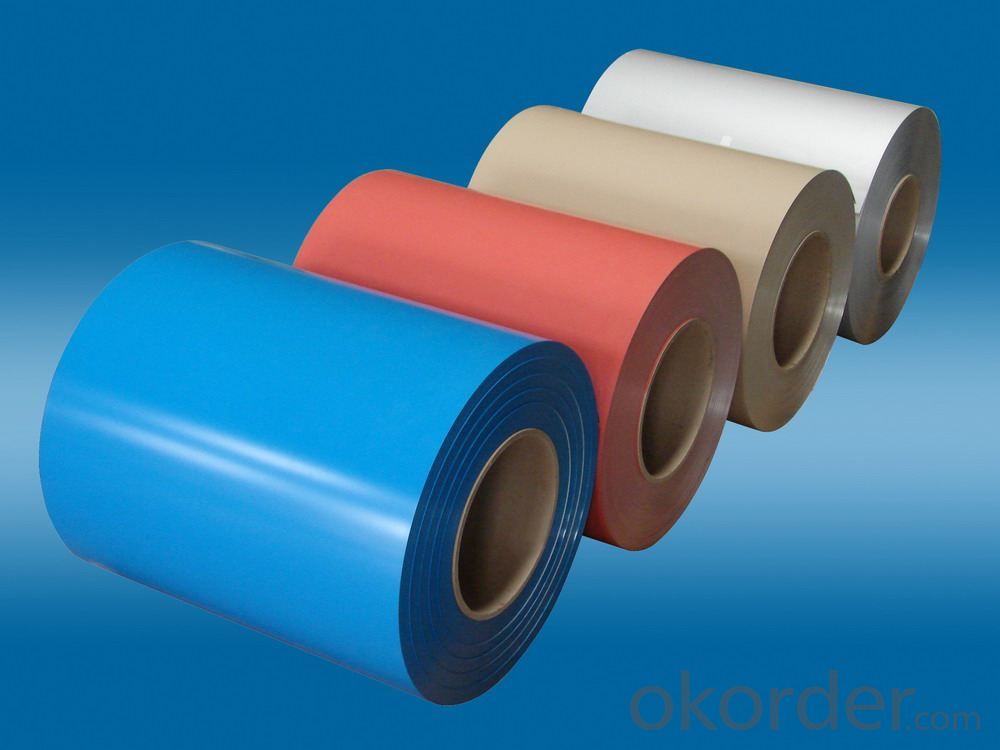

3.AA1xxx Coated Aluminum Coils Used for Construction Images

4. AA1xxx Coated Aluminum Coils Used for Construction Specification

Alloy | AA1xxx |

Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

Thickness | 0.03mm-3.0mm |

Width | 30mm-1700mm |

Coating | PE,PVDF,Epoxy |

Painting Thickness | Standard 16-25 Mic, max 40 Mic |

Color | According to RAL colors or customers' samples |

Standard | GB/T 17748-1999 |

5. FAQ of AA1xxx Coated Aluminum Coils Used for Construction

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: is general aluminum sheet fire-proof?

- general aluminum sheet is less fireproof than tinfoil.

- Q: What are the different methods of surface patterning aluminum sheets?

- There are several methods available for surface patterning aluminum sheets, each with its own advantages and applications. Some of the commonly used methods include: 1. Mechanical Etching: This method involves the use of abrasive materials, such as sandpaper or wire brushes, to create patterns on the surface of the aluminum sheet. By applying varying pressure and movement, desired patterns can be achieved. Mechanical etching is a cost-effective and versatile method, suitable for creating simple to complex patterns. 2. Chemical Etching: Also known as chemical milling, this method uses chemicals to selectively remove material from the aluminum surface, creating patterns. The aluminum sheet is coated with a resist and then immersed in an etchant solution that dissolves the exposed areas, leaving behind the desired pattern. Chemical etching allows for precise and intricate designs but requires careful control of the etching process. 3. Laser Engraving: This method utilizes a high-power laser beam to remove material from the aluminum surface and create patterns. The laser beam is controlled by computer software, allowing for precise and detailed designs. Laser engraving is suitable for both small and large-scale production and offers high accuracy and repeatability. 4. Embossing: In this method, the aluminum sheet is pressed between two dies that have raised patterns, creating a three-dimensional design on the surface. Embossing can be done through mechanical or hydraulic presses and is commonly used to add texture and aesthetic appeal to aluminum sheets, such as for decorative purposes or branding. 5. Printing: Various printing techniques can be used to apply patterns onto aluminum sheets. These include screen printing, where ink is forced through a mesh screen onto the aluminum surface, and digital printing, which uses inkjet technology for high-resolution patterns. Printing methods allow for a wide range of colors and designs, making them suitable for decorative applications. The choice of surface patterning method depends on factors such as the desired pattern complexity, production volume, cost considerations, and the intended end-use of the aluminum sheets. Each method offers unique advantages and limitations, and manufacturers can select the most appropriate technique based on their specific requirements.

- Q: Which kind of glue is best for bonding aluminum sheets?

- 502

- Q: What is the modulus of elasticity for aluminum sheets?

- The modulus of elasticity for aluminum sheets, also known as Young's modulus, is typically around 69 GPa (gigapascals) or 10 million pounds per square inch (psi). This value represents the measure of the stiffness or rigidity of the material. However, it is important to note that the modulus of elasticity can vary slightly depending on the specific alloy composition and tempering of the aluminum sheet.

- Q: What characteristics distinguish aluminum sheets from other types of sheets?

- <p>Aluminum sheets are lightweight, corrosion-resistant, and have excellent thermal and electrical conductivity. They are commonly used in construction, automotive, and packaging industries. In contrast, other types of sheets, such as steel sheets, are heavier and stronger but less resistant to corrosion. Plastic sheets are lightweight and flexible but have lower strength and thermal conductivity. Copper sheets offer high thermal and electrical conductivity but are more expensive and less resistant to corrosion than aluminum. Each type of sheet has unique properties that make it suitable for specific applications.</p>

- Q: What is the density of aluminum sheets?

- The density of aluminum sheets can vary depending on the specific alloy and thickness of the sheet. However, on average, the density of aluminum sheets falls between 2.6 to 2.8 grams per cubic centimeter (g/cm³). It is important to note that this value may change slightly based on the specific manufacturing process and any additional coatings or treatments applied to the sheets.

- Q: how to make aluminum products bright? How to polish or clean the products punch formed by 0.3mm aluminum sheet?

- you can try to grind it with magnetic grinder.

- Q: Can aluminum plate protect against radiation?

- It can only about radiation, and other materials have not heard of this performance.

- Q: How do aluminum sheets perform in terms of thermal expansion and contraction?

- Aluminum sheets have a relatively high coefficient of thermal expansion, meaning they expand more than other materials when heated and contract more when cooled.

- Q: Iron is extracted from iron oxide by displacement with carbon.But aluminum is not extracted from aluminium oxide using displacement by carbon. Suggest a reason for this.

- Well, de facto because the heat of formation of aluminum oxide is so much greater than the heat of formation of iron oxide. If you're looking for something more mechanistic, find Al and Fe in the periodic table. Al and Fe are in different rows, and Fe is larger than Al, so although Al+3 and Fe+3 have the same charge, oxygen bonds less strongly to Fe+3 than to Al+3 because it's further away from the nucleus of Fe. Al+3 has no outer shell electrons at all; 3s, 3p, and 3d subshells are all empty. It's effectively a charged sphere with nothing to interfere with bonding. Fe+3 (as in hematite, Fe2O3) is larger, has filled 3s and 3p subshells, and a half-filled 3d subshell. That 3d electron density projects pretty far out into space, holding oxygen at arms length. Aluminum has no electron density in 3d orbitals, so oxygen can tuck in nice and tight and get a good grip. Any of these hit the mark? I don't know what background you're bringing to this question.

Send your message to us

Welding Aluminum Sheets - AA1XXX Coated Aluminum Coils for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords