Alumco Manufactures Aluminum Sheets - Aluminium Coils AA3003 for Coated Coils Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

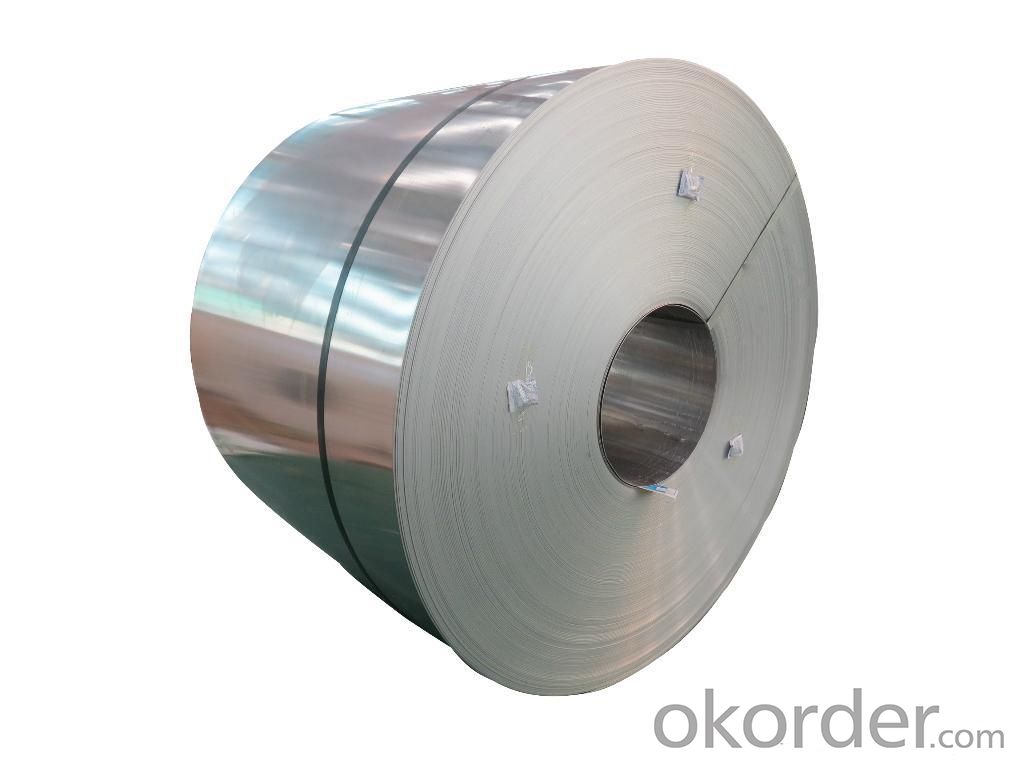

1.Structure of Aluminium Coils AA3003 for Manufacturing Coated Coils Description

The aluminum content of Aluminium Coils AA3003 for Manufacturing Coated Coils is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminium Coils AA3003 for Manufacturing Coated Coils is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of the Aluminium Coils AA3003 for Manufacturing Coated Coils

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.Aluminium Coils AA3003 for Manufacturing Coated Coils Images

4.Aluminium Coils AA3003 for Manufacturing Coated Coils Specification

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc. |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminium Coils AA3003 for Manufacturing Coated Coils

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminium Coils AA3003 for Manufacturing Coated Coils products.

B.When will you deliver the products?

Aluminium Coils AA3003 for Manufacturing Coated Coils will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: How many molecules are in 1 square foot of aluminum foil?

- Since aluminum foil is an amalgamation of various metals you would first need to know the full chemical breakdown in order to determine how many molecules there are in a square foot of aluminum foil. That said, if your foil was 100% aluminum, you could determine the number of AL atoms by first determining the mass of the foil and dividing by the molecular weight of AL. Multiply that by 6.022 x 10^23 to determine the number of atoms.

- Q: Are aluminum sheets resistant to vibration?

- Aluminum sheets, in general, demonstrate resistance towards vibration. Being a lightweight and flexible material, aluminum possesses excellent damping characteristics, enabling it to effectively absorb and dissipate vibrations. Moreover, aluminum exhibits a high strength-to-weight ratio, ensuring its structural integrity remains intact under vibrating conditions. Consequently, aluminum sheets are highly favored in sectors like aerospace, automotive, and construction, where protection against vibrations is crucial. Nevertheless, it is important to acknowledge that the degree of vibration resistance may differ depending on various factors such as the thickness and alloy composition of the aluminum sheet, as well as the intensity and frequency of the vibrations.

- Q: When zinc dust and sulfur dust are combined in certain proportional ratios and ignited, a violent exothermic reaction occurs. Because the reaction only depends on two components; zinc and sulfur, but not oxygen, the reaction has all of the components that it needs within the mixture. The same is also true for a mixture of magnesium and sulfur.However, the same reaction does not occur with iron and sulfur. Instead, the mixture reacts slowly over a period of a few minutes rather than flashing to smoke in less than a second. Now for my questions:1: If aluminum and sulfur were combined in the same proportional ratios as the zinc and the magnesium mixtures were, would the reaction be as fast as the zinc and the magnesium mixtures? Why or why not?2: What properties of the different metals used in these mixtures makes them behave so differently?

- 1. This depends on the aluminium particle size and it's quality as Al is normally coated with an oxide layer that protects the Al metal underneath. Assuming that the Al powder was good stuff, it should react as violently as the Zn and Mg mixtures. Why .. because it is a very reactive metal ... see further info below. However I needed tried it. 2. The difference is really about the reactivity. Iron, although a reactive metal, is far less reactive than Mg,Al, and Zn. I have tried the zinc and sulphur a number of times and it is really quite violent. With a fair quantityof reactants in the lab it produced an excellent mushroom smoke cloud. I've also seen the Al reactivity demonstrated by a mad Chemistry prof from Nottingham University. He mixed Al powder into a paste with liquid oxygen and ignited it! Wow ... what a reaction.I shall never forget it although it was about 35 years ago!

- Q: Do 101 aluminum sheets have any specific certifications or standards?

- Yes, 101 aluminum sheets typically have certifications and standards that ensure their quality and performance. These may include certifications like ASTM (American Society for Testing and Materials) and standards such as AA (Aluminum Association) standards, which verify the material's composition, mechanical properties, and manufacturing processes. Additionally, specific industry certifications like ISO 9001 (International Organization for Standardization) may be applicable to ensure consistent quality control during production.

- Q: Can aluminum sheet be used for aerospace structural components?

- Yes, aluminum sheet can be used for aerospace structural components. Aluminum is commonly used in the aerospace industry due to its desirable properties such as low density, high strength-to-weight ratio, and excellent corrosion resistance, making it suitable for various structural applications in aircraft and spacecraft.

- Q: Are the aluminum sheets available in different finishes (e.g., brushed, polished)?

- Aluminum sheets can be obtained in various finishes, such as brushed or polished, providing different surface textures and appearances. These finishes are achieved by employing diverse processes that modify the aluminum sheets. Brushed finishes, for instance, create a textured pattern by delicately brushing the surface with fine abrasive materials, resulting in a satin-like look. Conversely, polished finishes involve utilizing abrasive compounds or polishing wheels to buff the surface to a high shine. Consequently, these distinct finishes enable the customization and versatile utilization of aluminum sheets across different industries.

- Q: What is the fatigue strength of 101 aluminum sheets?

- The maximum stress level that 101 aluminum sheets can endure without experiencing fatigue failure is known as their fatigue strength. Typically, fatigue strength is determined by subjecting the material to repeated cyclic loading until failure occurs. However, it is important to understand that the fatigue strength can vary depending on various factors, such as the thickness of the sheet, its surface condition, heat treatment, and other mechanical properties. Therefore, it is not possible to provide an accurate value for the fatigue strength of 101 aluminum sheets without specific information about these variables. To obtain the fatigue strength of 101 aluminum sheets, it is recommended to refer to the material's technical datasheet or contact the manufacturer or supplier for precise information. They can provide details on the fatigue properties, including the endurance limit or the stress level at which the material can withstand an unlimited number of cycles without experiencing fatigue failure.

- Q: Can aluminum sheets be used for automotive applications?

- Yes, aluminum sheets can be used for automotive applications. Aluminum is a lightweight and corrosion-resistant material, making it ideal for various automotive components. It is commonly used in the construction of car bodies, engine parts, wheels, and other structural components. Aluminum sheets offer excellent strength-to-weight ratio, which helps improve fuel efficiency and overall performance of vehicles. Additionally, aluminum has good thermal conductivity, allowing for effective heat dissipation in automotive applications. Overall, the use of aluminum sheets in automotive manufacturing has become increasingly popular due to its numerous advantages.

- Q: Could ring-pull can be transformed as aluminum sheet?

- Ring-pull cans will be reused after recycle, there are parts of ring-pull cans be transformed as aluminum sheet.

- Q: Are aluminum sheets suitable for thermal insulation?

- No, aluminum sheets are not suitable for thermal insulation on their own. While aluminum is a good conductor of heat and electricity, it does not have good insulating properties. In fact, aluminum sheets can actually transfer heat instead of blocking it, making them ineffective for thermal insulation purposes. For proper thermal insulation, materials with low thermal conductivity, such as fiberglass, mineral wool, or foam boards, are commonly used. These materials are designed to trap air or create a barrier that reduces the transfer of heat, ensuring effective insulation.

Send your message to us

Alumco Manufactures Aluminum Sheets - Aluminium Coils AA3003 for Coated Coils Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords