China Aluminum Frame Extrusion Profiles - Large Cross Extrusion Section for Tubes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

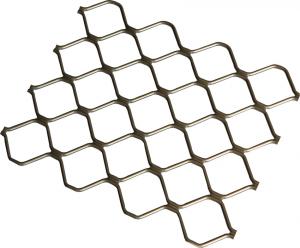

Large Cross Extrusion Section For Tubes

1. Surface: Mill surface treatment or others.

2. Alloy:6082T6 alloy temper

3. Size:various dimensions in order to meet customer’s requirement

4. Life time: Last for 50 years

5. Standard: EN755-9 standard

6. Advantage:

The tubes are resistant to water corrosion, many marine-based industries use these tubes to make parts. Tubes made from this metal are used to manufacture submarines, ships, boats and large ferries. Also many large industries have started using tubes made from aluminium because it is easy to make designs and shapes from these tubes. Another benefit of using these tubes is that their thickness can be varied depending on the specification required.

The alloy temper with 6082 T6 which allows this structure to maintain good formability, good weldability, high hardness, good workability and good interface characteristics. Easy processing, easy coating and good corrosion resistance, oxidation resistance.

7. Package:

Each profile is wrapped by the particular paper to avoid the scratching between each profile and also prevent the moisture in the air. Outside the bundle is fixed with the four wooden boards including support board vertically and base board on horizontal level. There are steel belts outside the boards to strap and tighten.

- Q: This question asks for the various types of aluminum profiles that are utilized in roofing systems.

- <p>Aluminum profiles for roofing systems come in various types, each serving specific purposes. Common types include: 1. <strong>Gutter Profiles</strong>: Used for collecting and directing rainwater from the roof. 2. <strong>Fascia Profiles</strong>: Cover the ends of rafters and provide a finished edge to the roof. 3. <strong>Soffit Profiles</strong>: Installed under the eaves to allow ventilation and conceal the underside of the roof. 4. <strong>Purlin Profiles</strong>: Support the roof sheeting and are placed perpendicular to the rafters. 5. <strong>Rafter Profiles</strong>: Mimic traditional wooden rafters and provide structural support. 6. <strong>Roof Ridge Profiles</strong>: Cap the ridge of the roof, where two slopes meet. 7. <strong>Hip and Valley Profiles</strong>: Used at the intersection of two sloping roof surfaces. Each profile is designed to withstand weather conditions and provide durability, with specific dimensions and shapes tailored to the roofing system's requirements.</p>

- Q: What are the various finishes or coatings that can be applied to aluminum profiles to enhance their appearance, durability, or functionality?

- <p>Aluminum profiles can be coated with a variety of options to improve their aesthetic appeal, corrosion resistance, and performance. These include anodizing, which creates a protective oxide layer; powder coating, offering a wide range of colors and textures; electrophoretic coating, known for its smooth finish; and thermal spraying, which involves applying a coating through a high-velocity flame. Other options are painting, which can be done in various colors, and polishing, which gives a shiny finish. Each coating option has its specific benefits and applications, depending on the requirements of the project.</p>

- Q: Are there any specific maintenance requirements for aluminum profiles?

- Yes, aluminum profiles require regular maintenance to ensure their longevity and performance. This includes cleaning the profiles regularly to remove dirt, dust, and debris. It is also important to check for any signs of corrosion or damage and address them promptly. Additionally, lubricating moving parts and hinges can help to maintain smooth operation. Finally, following the manufacturer's guidelines and recommendations for maintenance is essential to keep the aluminum profiles in optimal condition.

- Q: How do you prevent discoloration or fading of aluminum profiles?

- To prevent discoloration or fading of aluminum profiles, it is important to apply a protective coating or finish on the surface of the profiles. This can be done using methods such as anodizing, powder coating, or painting. These coatings act as a barrier, shielding the aluminum from exposure to UV rays, moisture, and other environmental factors that can cause discoloration and fading. Regular cleaning and maintenance also play a crucial role in preventing discoloration, as removing dirt, grime, and pollutants promptly can help preserve the appearance and integrity of the aluminum profiles.

- Q: Shenzhen aluminum profile manufacturers which good?

- How to choose the industrial aluminum profiles, this problem for the just contact with industrial aluminum profile friends, is really a serious problem to consider.That selection of industrial aluminum manufacturers is not good, money, goods is not good, he can give you redo is OK, but also take time; meet industrial aluminum manufacturers some black, and you may be wrangling, that egg pain.

- Q: Can aluminum profiles be used in marine environments?

- Yes, aluminum profiles can be used in marine environments. Aluminum is often chosen for its excellent corrosion resistance and lightweight properties, making it ideal for marine applications. It is commonly used in the construction of boats, shipbuilding, and offshore structures due to its durability and ability to withstand exposure to saltwater and harsh weather conditions.

- Q: Are aluminum profiles suitable for use in roofing or wall systems?

- <p>Yes, aluminum profiles are commonly used for both roofing and wall systems due to their durability, corrosion resistance, and lightweight properties. They offer a modern aesthetic and can be easily integrated into various architectural designs. Aluminum profiles are also known for their strength and flexibility, allowing for the creation of complex shapes and structures. Additionally, they require minimal maintenance and can withstand harsh weather conditions, making them a popular choice for construction projects.</p>

- Q: This question asks for the method to determine the quantity of aluminum profiles required for a construction project.

- <p>To calculate the amount of aluminum profiles needed for a building project, follow these steps: 1. Determine the architectural design and specifications of the project to understand where aluminum profiles will be used. 2. Measure the dimensions of the areas requiring aluminum profiles, such as window frames, door frames, or structural supports. 3. Calculate the total linear footage of aluminum needed by multiplying the length of each profile by the number of profiles required. 4. Factor in additional materials for joints, connections, and potential waste. 5. Consult with suppliers or use industry-standard conversion factors to determine the weight or volume of aluminum profiles based on the linear footage. 6. Review the calculations and adjust for any changes in the project design. This process ensures you have the correct amount of aluminum profiles for your construction needs.</p>

- Q: How do you clean and maintain aluminum profiles?

- Here are some straightforward steps to clean and maintain aluminum profiles: 1. Begin by eliminating loose dirt or debris from the aluminum profiles' surface using a soft brush or cloth. 2. Create a cleaning solution by combining warm water with mild dish soap or a non-abrasive cleaner. Avoid using harsh chemicals or abrasive cleaners since they can harm the aluminum finish. 3. Immerse a gentle cloth or sponge into the cleaning solution and delicately scrub the aluminum profiles, ensuring that all corners and crevices are thoroughly cleaned. 4. Rinse the profiles with clean water to remove any soap residue. You can accomplish this by using a hose or a bucket of water. 5. Dry the aluminum profiles entirely using a soft, lint-free cloth. This will prevent the formation of water spots or streaks. 6. For routine maintenance, you can employ a specialized aluminum cleaner or polish to restore the shine and safeguard the surface. Follow the product instructions for optimal outcomes. 7. It is crucial to refrain from using abrasive scrubbers, steel wool, or harsh chemicals as they can scratch or damage the aluminum finish. Additionally, never apply acidic cleaners or vinegar on aluminum since they can cause corrosion. 8. If you happen to notice any scratches or minor damages on the aluminum profiles, you can employ a touch-up paint specifically designed for aluminum to repair them. Follow the manufacturer's instructions for application. Always remember that regular cleaning and maintenance will aid in preserving the appearance and longevity of your aluminum profiles.

- Q: What are the different extrusion processes used for aluminum profiles?

- There are several different extrusion processes used for aluminum profiles, including hot extrusion, cold extrusion, indirect extrusion, and direct extrusion. In hot extrusion, the aluminum is heated to a high temperature and forced through a die to create the desired profile. Cold extrusion involves forming the aluminum at room temperature using high pressure. Indirect extrusion involves pushing the aluminum billet through a stationary die, while direct extrusion involves pushing the billet through a moving die. Each process has its own advantages and is used for different applications in the manufacturing of aluminum profiles.

Send your message to us

China Aluminum Frame Extrusion Profiles - Large Cross Extrusion Section for Tubes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords