China Aluminum Coil - Aluminum Master Casting Coil 6-8mm in Alloys 1xxx, 3xxx, 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

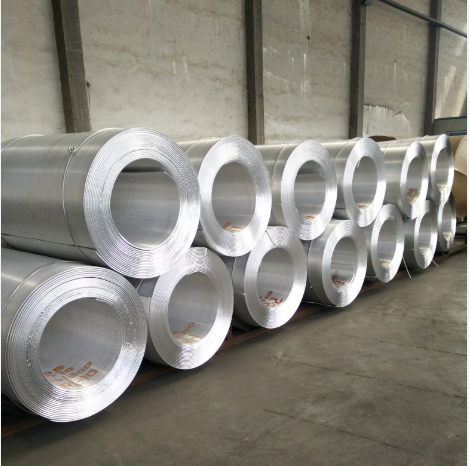

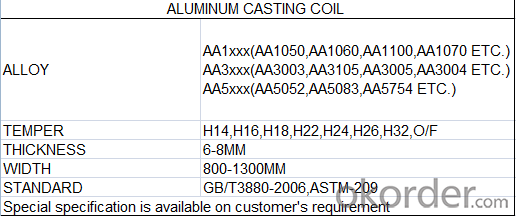

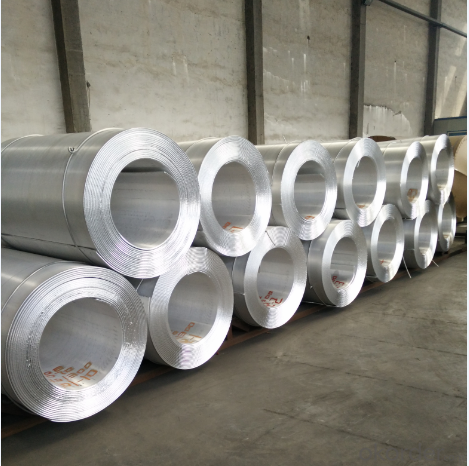

1.Structure of Aluminum Master Casting Coil 6-8mm in Alloys:

Aluminum Master Casting Coil 6-8mm in alloys is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. Hot rolled y cold rolled son available. The thickness of Aluminum Casting Coil for thin coil is about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the Aluminum Master Casting Coil 6-8mm in alloys:

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

3. Aluminum Master Casting Coil 6-8mm in Alloys

4. Production Process of Aluminum Master Casting Coil 6-8mm in Alloys

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of Aluminum Master Casting Coil 6-8mm in Alloys

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q: This question asks about the environmental friendliness of aluminum coils.

- <p>Aluminum coils are considered environmentally friendly for several reasons. They are highly recyclable, with the recycling process requiring significantly less energy compared to producing new aluminum. This reduces greenhouse gas emissions and conserves resources. Additionally, aluminum is a non-toxic material that does not leach harmful substances into the environment. However, the environmental impact also depends on the production process, which can consume energy and generate emissions. Overall, when properly recycled, aluminum coils have a lower environmental footprint than many other materials.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing spring steel wire coils.

- <p>Spring steel wire coils offer several advantages such as high strength and durability, making them ideal for applications requiring resilience and resistance to deformation. They are also known for their excellent elasticity, which allows for consistent performance in dynamic applications. Additionally, spring steel wire coils can be easily formed into various shapes, providing versatility in design and functionality. However, they also have disadvantages, including potential for corrosion if not properly treated, and they can be more expensive than other types of wire due to the material's properties. Furthermore, spring steel wire coils may require specialized tools and equipment for handling and installation, adding to the cost and complexity of their use.</p>

- Q: What’s the production standard of aluminum coil?

- GB/T3880-2006 mechanical standard GB/T3190-1996 chemical standard

- Q: How are aluminum coils protected during shipping?

- To guarantee the safety of aluminum coils during shipping and prevent any potential harm, various methods are employed. One frequently used approach involves the utilization of protective packaging materials, such as bubble wrap, foam, or corrugated cardboard, which are employed to envelop the coils. This wrapping creates a cushioning effect that absorbs any impact or vibration that may occur during transportation. In addition to these protective packaging materials, aluminum coils are often placed within robust shipping containers or crates. The design of these containers aims to provide enhanced security and stability during transit, thereby minimizing the risk of the coils being jostled or bumped. Furthermore, to maintain the coils' integrity and decrease the possibility of damage caused by friction with other objects, strapping or banding is frequently employed to secure the coils and prevent any shifting or movement during transportation. Moreover, shipping companies may also employ air-bag systems or dunnage bags to fill any empty spaces within the shipping container. This additional measure further reduces movement and adds an extra layer of protection for the coils. In summary, the protection of aluminum coils during shipping involves a combination of packaging materials, secure containers, and preventive measures to ensure their safe arrival at their intended destination.

- Q: This question asks for the most effective methods to clean an aluminum coil, which is a common component in various industries.

- <p>The best ways to clean aluminum coils involve a combination of mechanical and chemical processes. Mechanical cleaning can be done using brushes or pressure washing to remove loose dirt and debris. Chemical cleaning involves using a suitable aluminum cleaner or mild detergent solution to dissolve stubborn grime. Always rinse thoroughly with water to remove any residue. Avoid abrasive materials or harsh chemicals that could scratch the surface. Regular cleaning and maintenance can prevent buildup and extend the coil's lifespan.</p>

- Q: How do aluminum coils contribute to the insulation properties of products?

- The insulation properties of various products are greatly enhanced by aluminum coils, playing a crucial role. The utilization of aluminum coils in insulation systems leads to improved thermal efficiency, decreased heat transfer, and reduced energy consumption. To begin with, aluminum possesses excellent heat and electricity conducting abilities. This particular characteristic enables aluminum coils to distribute and dissipate heat effectively, preventing the transfer of thermal energy from one side of the product to the other. Consequently, aluminum coils act as a barrier, minimizing the loss or gain of heat, which is essential for maintaining optimal temperatures across different applications. Additionally, aluminum coils exhibit low thermal conductivity. This implies that they are not easily affected by temperature changes and do not efficiently transfer heat. As a result, products incorporating aluminum coils can better withstand external temperature fluctuations, providing superior insulation against hot or cold conditions. Moreover, aluminum coils are lightweight, allowing for easy handling and installation in various products. This lightweight attribute is advantageous as it does not impose significant weight on the overall structure, making it suitable for industries requiring portable or lightweight insulation solutions. Furthermore, aluminum possesses high resistance to corrosion, making it ideal for applications in humid or corrosive environments. This durability ensures that the insulation properties of products containing aluminum coils remain effective over an extended period, without deterioration or compromise in performance. Additionally, aluminum is a recyclable material, aligning with sustainable practices. The use of aluminum coils in insulation products promotes environmental consciousness by reducing waste and energy consumption associated with the manufacturing of new materials. In conclusion, aluminum coils contribute significantly to the insulation properties of products by effectively distributing and dissipating heat, minimizing heat transfer, and resisting temperature fluctuations. Their lightweight nature, durability, and recyclability further augment their effectiveness as an insulation component. Overall, aluminum coils represent a valuable addition to insulation systems, enhancing thermal efficiency and decreasing energy consumption.

- Q: Domestic production of color coated aluminum coil manufacturers which good?

- Color coated aluminum coil has two kinds of polyester color coating and fluorocarbon coating. It is widely used in the field of architectural decoration, such as aluminum ceiling, aluminum plate and so on. There are many manufacturers of color coated aluminum rolls, big and small.

- Q: This question asks about the environmental effects associated with the use of aluminum coils.

- <p>The environmental impacts of using aluminum coils include energy consumption during production, potential release of greenhouse gases, and waste generation. Aluminum production requires significant energy, contributing to carbon emissions. Additionally, the extraction of bauxite, the primary source of aluminum, can lead to habitat destruction and water pollution. However, aluminum is highly recyclable, and recycling it saves energy and reduces waste. Proper disposal and recycling practices can mitigate some of these impacts, making aluminum a more sustainable choice when managed correctly.</p>

- Q: How do aluminum coils perform in corrosive environments?

- Aluminum coils perform exceptionally well in corrosive environments due to their inherent properties and protective coatings. Aluminum has a natural oxide layer that forms on its surface when exposed to air, creating a protective barrier against corrosion. This oxide layer is highly resistant to many corrosive agents, such as saltwater, acids, and atmospheric pollutants. Additionally, aluminum coils can be further protected with various coatings and treatments to enhance their resistance to corrosion. These coatings can include organic coatings, such as paint or lacquer, or inorganic coatings like anodizing or chemical conversion coatings. The combination of aluminum's natural oxide layer and additional protective coatings makes aluminum coils highly durable and reliable in corrosive environments. This resistance to corrosion is particularly beneficial in industries such as marine, chemical processing, and coastal applications, where exposure to saltwater or aggressive chemicals is common. Moreover, aluminum coils are lightweight, which adds to their versatility and ease of installation, making them suitable for a wide range of corrosive environments. This lightweight property also contributes to reducing transportation costs and energy consumption during installation. In summary, aluminum coils are well-suited for corrosive environments due to their natural corrosion resistance and the availability of protective coatings. Their durability, lightweight nature, and resistance to corrosion make them an optimal choice for various industries and applications, where longevity and performance are crucial factors.

- Q: When they say to coat entire roof system with Aluminum coating, what does that mean? The area to coat is NOT the ceramic barrel tiles of a roof but the flat section covered with tar paper and granules of shiny sand. Is it a liquid? Clear? Good for the roof.? How is it applied?

- Why you would be coating a flat roof with Aluminum coating is beyond anything I have learned. Flat roofs should have a felt and tar coating to water proof them. Aluminum roof coating is used mostly on mobile homes to reflect heat because mobile homes don't have attics to trap the heat and carry it to vents. It also seals the water out at the metal seams. Aluminum coating is a type of polymer that has aluminum flakes in it. It is brushed on like a thick coat of paint and allowed to dry.

Send your message to us

China Aluminum Coil - Aluminum Master Casting Coil 6-8mm in Alloys 1xxx, 3xxx, 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords