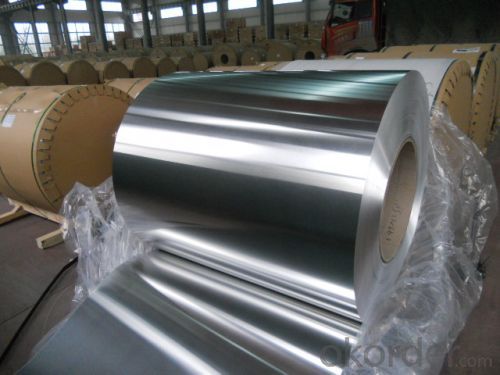

Roll Aluminum Coil for Building, Vehicle Construction, and Electronics Products 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Details: | Standard export packing or following customer's demand |

Delivery Detail: | Within 25-30 days or according to the order quantity |

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.05~10mm |

Width | <1600mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

Payment | L/C ,T/T |

Color coated Aluminum coil means coloring is processed onto the surface of aluminum coil by coating PE or PVDF paints. It is widely applied to many kinds of fields, like Aluminum composite panels, solid aluminum single panel, aluminum honeycomb panel, aluminum ceiling, aluminum roofing, pop-top cans, home appliance, electronic products etc.. By taking advantages of many features, such as stable property, anti-corrosion, 30years guarantee after special process, the lowest density in metals, the color coated aluminum become one of the most popular new materials.

| Aluminum Alloy Series | A1100, A3003, A3004, A3105, A5052, A8011 etc... |

| Coatings | PE or PVDF normally |

| Coating thickness | PE: no less than 18micron; PVDF: no less than 25micron; |

| Aluminum Thickness | 0.2mm ~ 1.5mm normally, could be custom-made |

| Width | For Coil:15mm ~ 1500mm normally; As per order For Sheet:500mm ~ 2000mm;As per order |

| Coil Interior Diameter | 150mm,405mm,505mm,508mm,510mm normally |

| Gloss | 10~90%, (EN ISO-2813:1994) |

| Other features | Please consult with us |

Coating Hardness (pencil resistance) | more than 2H |

| Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

| MEK resistance | More than 100 |

| Colors | RAL colors |

| Surface | embossed, mill finish, coated |

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

Our Services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3. We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

Photos

- Q: Can aluminum coils be used in the production of aluminum siding?

- Yes, aluminum coils can be used in the production of aluminum siding. Aluminum coils are commonly used in the manufacturing process of aluminum siding due to their durability, lightweight nature, and resistance to corrosion. These coils are usually processed through a coil coating line, where the aluminum is coated with a protective layer to enhance its performance and aesthetics. The coated aluminum coils are then formed and shaped into the desired siding panels, which can be installed on residential or commercial buildings. Aluminum siding is a popular choice for its low maintenance requirements, longevity, and ability to withstand various weather conditions.

- Q: The question asks if magnetic induction can be used to inspect the quality of an aluminum coil.

- <p>No, you cannot use magnetic induction to inspect the quality of an aluminum coil. Magnetic induction is a method used to detect flaws or discontinuities in ferromagnetic materials, such as steel, by inducing eddy currents. Aluminum is not a ferromagnetic material, so it does not retain magnetism or support the formation of eddy currents in the same way. Instead, other non-destructive testing methods like ultrasonic testing or radiographic testing may be more appropriate for inspecting the quality of aluminum coils.</p>

- Q: How are aluminum coils used in the production of beverage cans?

- Aluminum coils play a crucial role in the production of beverage cans. These coils are essentially flat, thin sheets of aluminum that are wound into a coil shape. Firstly, the aluminum coils are unwound and fed into a machine that coats them with a thin layer of a protective material, usually a polymer. This coating helps prevent the aluminum from reacting with the beverage and affecting its taste or quality. Next, the coated aluminum coils are passed through a series of rollers that gradually shape them into a cylindrical form. This process is known as cupping, where the flat coil is transformed into a cup-like shape. This cup will eventually become the body of the beverage can. Once the cups are formed, they are trimmed to the correct height and diameter. The excess aluminum is recycled to minimize waste. The cups are then cleaned and rinsed to remove any contaminants. After cleaning, the cups are passed through another machine that applies a liquid compound to their inner surface. This compound acts as a barrier between the aluminum and the beverage, preventing any potential reactions or contamination. Following this, the cups are shaped into the final can body by being pressed between a top and bottom mold. The molds are designed to give the cans their characteristic shape and ridges. Any excess aluminum is trimmed off, and the cans are once again cleaned to ensure their purity. Finally, the cans are sent for filling with the desired beverage, sealing, and labeling processes before being packaged and shipped for distribution. In summary, aluminum coils are used in the production of beverage cans by providing the raw material from which the cans are made. Through a series of processes including coating, cupping, shaping, and cleaning, the aluminum coils are transformed into the final can bodies. These cans are then filled, sealed, and labeled before they are ready for consumption.

- Q: Can aluminum coils be used in water treatment plants?

- Aluminum coils have a wide range of applications in water treatment plants due to their corrosion resistance and efficiency in heat transfer. They are commonly used in heat exchangers and condensers for optimal heat transfer. In water treatment plants, aluminum coils serve various purposes. For instance, they are utilized in cooling towers to effectively remove heat from water by circulating it over the coils. This process facilitates the transfer of heat from the water to the surrounding air, resulting in the cooling of the water. Moreover, aluminum coils are also employed in the construction of evaporators, which aid in the evaporation of water during the treatment process. These coils are designed to have a large surface area, maximizing contact between the water and the aluminum surface to enhance evaporation efficiency. Additionally, aluminum coils play a crucial role in air handling units (AHUs) within water treatment plants. AHUs help regulate temperature, humidity, and air quality in the facility. The aluminum coils in AHUs contribute to the overall efficiency of the system by cooling or heating the air passing through them. However, it is important to consider the compatibility of aluminum with the specific water being treated. Certain water compositions, such as those with low pH or high levels of certain chemicals, can cause corrosion or chemical reactions that may affect the performance and durability of aluminum coils. Therefore, it is essential to assess the water composition and seek guidance from experts or manufacturers to ensure the suitability of aluminum coils for a particular water treatment application.

- Q: What are the different color options for pre-painted aluminum coils?

- Pre-painted aluminum coils offer a multitude of color possibilities. The choices encompass solid colors like white, black, blue, red, green, yellow, and gray, among others. Moreover, there are metallic finishes, such as silver, gold, bronze, and copper, which create a captivating shimmer. Pastel shades, vibrant hues, and earth tones are also favored options. It is worth noting that the specific color range might differ depending on the manufacturer or supplier. Nevertheless, the overall assortment is extensive, ensuring that diverse design preferences and requirements are well accommodated.

- Q: Can aluminum coils be used for roofing applications?

- Yes, aluminum coils can be used for roofing applications. Aluminum is a popular choice for roofing due to its lightweight nature, durability, and resistance to corrosion. It is commonly used for both residential and commercial roofing projects.

- Q: I am looking for a place where I can have my aluminium channels anodized in Erode.

- KSR Agency Products Services Aluminum AnodisingAluminum ExtrusionsArchitectural GlassesBus BarComposite Panels Elevation Glass FittingsFalse CeilingHeat Sink Sections About Us KSR Agency is well-known, veteran-owned business enterprise. Our company is a promising manufacturer and supplier of wide range of Aluminum Extrusion channels and Anodizing Aluminum that includes the following products o Glass Fittings for Elevation o Bus Bars o Heat Sink Sections o Aluminum Extrusions o Architectural Glasses o False ceiling o Partitions o Composite Panels Our Anodizing methodologies: o Type I - Chromic Acid Anodize o Type II - Sulphuric Acid Anodize o Type III - Hard Anodize o Class 1 - Non-dyed o Class 2 - Dyed Our range of products has huge demand and widely accepted by many people all across for their outstanding features and are available in various patterns, designs, sizes, shapes. We use the best grade raw material and advanced methods of production in the process of manufacturing these products. Our products meet the international standards in quality that assures excellent performance in usage and customized as per the clients' specification and necessity. We deliver the orders within a stipulated time frame. Contact Details KSR Agency No. 45, Mudali Thottam, Bharathi Nagar, Sulai, Chittode Road, Erode - 638004, Tamil Nadu, India Mr. Sendhil Kumar +(91)-9739956109 Mr. Rajendran +(91)-9842876614

- Q: How are aluminum coils shipped and transported?

- Aluminum coils tend to be shipped and transported in various ways, depending on factors like size, weight, and destination. Below are a few common techniques: 1. Utilizing flatbed trucks: Flatbed trucks are frequently employed when shipping smaller aluminum coils for shorter distances. These coils are securely loaded onto the flatbed and fastened with straps or chains to prevent any movement during transportation. 2. Opting for intermodal containers: When shipping aluminum coils over longer distances, intermodal containers are a popular choice. These containers can be loaded onto trucks, trains, or ships, providing versatility. The coils are typically stacked and secured within the container using bracing or blocking materials to avoid any shifting. 3. Employing rail transport: Rail transport is also an option for transporting aluminum coils, particularly over longer distances. Coils are loaded onto flatcars or specialized coil cars that have built-in cradles or bolsters to securely hold the coils in place during transit. 4. Utilizing vessels: For international or distant shipments of aluminum coils, sea transport via cargo vessels is often used. Coils are carefully loaded into the cargo hold of the vessel and secured with lashings or other methods to prevent any movement or damage during the voyage. Regardless of the chosen transportation method, it is crucial to ensure that the aluminum coils are adequately protected from moisture, dust, and other potential sources of damage during transit. Packaging materials like moisture-resistant wrapping, protective covers, or crates are employed to safeguard the coils and maintain their quality until they reach their destination.

- Q: What are the different coil lengths available for aluminum coils?

- Aluminum coils come in a variety of lengths, depending on the specific application and requirements. Typically, these lengths range from a few feet to several hundred feet. The most commonly used coil lengths in industries like HVAC, automotive, and construction are 50 feet, 100 feet, and 250 feet. However, it is worth mentioning that custom coil lengths can also be produced to meet the customer's specific needs. These custom lengths may vary depending on factors such as coil thickness, width, and intended use. Ultimately, the available coil lengths for aluminum coils are adaptable and can be customized to meet the demands of various industries and applications.

- Q: Is it safe to use aluminum coil for storing food?

- <p>Aluminum coil can be used for food storage, but with certain considerations. Aluminum is a good conductor of heat and is often used in cookware, but for long-term food storage, it's not ideal. It's important to ensure that the aluminum is coated or lined with a non-reactive material to prevent direct contact with food, as aluminum can leach into food and may have health implications. Additionally, aluminum is not recommended for acidic foods as it can react with them. For best food storage practices, consider using materials specifically designed for food contact, such as glass or food-grade plastic containers.</p>

Send your message to us

Roll Aluminum Coil for Building, Vehicle Construction, and Electronics Products 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords