Aluminum Coils Tampa Fl - Alu Coil for Casting Stock 6-8mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

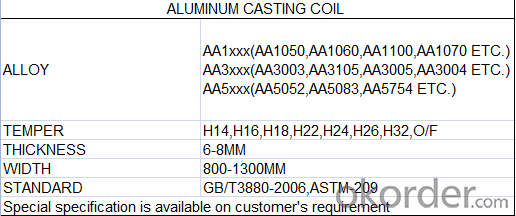

Alu Coil for Casting Stock from 6-8mm Thick

1.Structure of Alu Coil for Casting Stock from 6-8mm Thick

Alu Coil for Casting Stock fron 6-8mm Thick is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. The thickness of Aluminum Coil for Casting to Thinner Coils is about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the Alu Coil for Casting Stock from 6-8mm Thick

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

3. Alu Coil for Casting Stock from 6-8mm Thick

4. Production Process of Alu Coil for Casting Stock from 6-8mm Thick

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of Alu Coil for Casting Stock from 6-8mm Thick

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q: How are aluminum coils joined together to form larger panels?

- Aluminum coils are joined together to form larger panels through a process known as coil joining or coil-to-panel joining. This process typically involves the use of a coil joining machine, which is designed to connect multiple coils of aluminum together seamlessly. The first step in this process is to feed the individual coils into the machine. The machine then unwinds the coils and brings them together, aligning them side by side. The edges of the coils are typically overlapped slightly to ensure a secure and continuous connection. Once the coils are aligned, the machine uses various techniques to bond them together. One common method is through the use of heat and pressure. The machine applies heat to the overlapping edges of the coils, softening the aluminum and allowing it to fuse together. Simultaneously, pressure is applied to ensure a strong bond is formed. Another method of joining aluminum coils is through the use of mechanical fasteners. In this case, the machine will punch holes through the overlapping edges of the coils and insert fasteners, such as screws or rivets, to hold them together securely. After the coils are joined, the machine continues to feed the connected coils forward, allowing for continuous production of larger panels. The excess material from the overlapping edges is typically trimmed off, resulting in a smooth and seamless panel. Overall, the process of joining aluminum coils to form larger panels requires precision and specialized machinery. The resulting panels are durable, lightweight, and commonly used in various industries such as construction, automotive, and aerospace.

- Q: I recently had to have a course of B-12 injections (my digestive system was not properly absorbing other forms). While I felt a significant improvement in mood, energy and memory, I was very concerned to discover that the B-12 shot came with a little something extra: aluminum! I'm wondering if the benefits outweigh the potential risks - why is aluminum placed in the injection? (Are there metal free versions out there?)

- Aluminum salts have been used in vaccines for over 80 years now. They are thought to increase the body's immune response to the vaccines although it is not clear to researchers how this works. However, there is no evidence that it is harmful and the only side effect seems to be increased reddness. The odd thing is that there is usually some sort of metal in any vaccine/shot. If not aluminum salts, there's thimerosal (a mercury-based preservative). The CDC says, btw, that there is no proof that thimerosal causes any harm. However, some studies show a link between thimerosal, aluminum, and a host of other preservatives added to vaccines to autism in children. No news on how it affects adults, but research is being done with respect to Alzheimer's disease. Speak to your doctor to find out he/she has 'metal free' versions of vaccines and about your concerns. Such vaccines are available but are usually very costly to obtain manufacture so doctors usually don't order them as a result.

- Q: Are aluminum coils suitable for architectural facades?

- Yes, aluminum coils are suitable for architectural facades. They are lightweight, durable, corrosion resistant, and can be easily formed into various shapes and sizes. Additionally, aluminum coils offer a wide range of finishes and colors, making them a versatile choice for architectural facades.

- Q: Can aluminum coils be painted or printed on?

- Yes, aluminum coils can be painted or printed on. Aluminum is a versatile material that can be coated or painted to achieve various finishes and colors. The surface of aluminum coils can be prepared through a process called pre-treatment, which involves cleaning, etching, and applying a primer. This prepares the surface for painting or printing. Painting aluminum coils involves applying a coating system that typically consists of a primer, a color coat, and a topcoat for protection. The paint can be applied using various methods such as spraying, roll coating, or coil coating. Coil coating, in particular, is a commonly used method where the paint is applied to the coil before it is formed into the desired shape. This ensures a uniform and consistent finish. Printing on aluminum coils is also possible using different techniques such as screen printing, digital printing, or lithography. These methods allow for detailed designs, patterns, or even photographs to be printed onto the surface of the aluminum coil. It is important to note that the choice of paint or printing method may depend on the specific requirements of the application, such as durability, weather resistance, or aesthetic preferences. Additionally, proper surface preparation, selection of suitable coatings, and adherence to recommended application guidelines are essential for ensuring a successful and long-lasting paint or print finish on aluminum coils.

- Q: I have the Samp;W Mamp;P 15 rifle and was wondering if I should oil the exterior of the rifle. The receiver material is 7075 T6 Aluminum and the finish is Hard Coat Black Anodized (specifications on website). Any advice or tips are welcome! Thanks!

- As chris w said, aluminum doesn't rust and anodizing prevents corrosion. Have you considered simply reading the manual that comes with your rifle? The manual includes instructions for cleaning and care, and if you don't have one, you can download it from SW's website.

- Q: I would like to know because I'm getting a sword with an aluminum sheathe.

- wouldnt advise,it might bend Aluminium is a soft, lightweight metal with appearance ranging from silvery to dull gray, depending on the surface roughness. Aluminium is nontoxic, nonmagnetic, and nonsparking. The yield strength of pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from 200 MPa to 600 MPa.[1] Aluminium has about one-third the density and stiffness of steel. It is ductile, and easily machined, cast, and extruded.

- Q: How are aluminum coils typically stored and transported?

- Aluminum coils are typically stored and transported in a horizontal position. They are often secured with straps or bands to prevent movement during transportation. Additionally, they are usually stored in a covered or enclosed area to protect them from environmental factors such as moisture or dust.

- Q: What are the potential applications of patterned aluminum coils?

- Patterned aluminum coils possess a wide array of possible applications across diverse industries. The construction industry, in particular, benefits greatly from the utilization of patterned aluminum coils. These coils find use in roofing, siding, and cladding applications. The patterned surface serves to augment the visual appeal of buildings while also providing added strength and durability. Another industry that can benefit from the implementation of patterned aluminum coils is transportation. These coils can be employed in the manufacture of automotive parts such as body panels, trims, and decorative accents. The patterned surface imparts a distinctive and stylish appearance to vehicles, all the while offering corrosion resistance and lightweight properties. Patterned aluminum coils can also be employed in the production of household appliances and furniture. They can be utilized to create decorative panels, cabinets, and countertops. The patterned surface can add a contemporary and sophisticated touch to these products, thereby rendering them more visually appealing to consumers. Moreover, patterned aluminum coils find applications in the packaging industry. They can be utilized in the fabrication of packaging materials such as cans, containers, and lids. The patterned surface can make the packaging more captivating, thereby aiding in attracting customers and bolstering sales. Furthermore, patterned aluminum coils can be incorporated into the production of signage and advertising materials. The patterned surface offers a unique and attention-grabbing appearance, which makes it ideal for crafting signage that stands out and effectively communicates messages. In summary, the potential applications of patterned aluminum coils are extensive and diverse. From construction to transportation, household appliances to packaging, and signage to advertising, these coils offer a versatile solution for enhancing aesthetics, durability, and functionality across various industries.

- Q: Supposably water ozidies it what ever that means so how in the world do i clean an aluminum bike if i cant use water? i like to use water and soap on my carbon bike so what do i use on a aluminum?

- For painted metal, supports, grips, vinyl seat, tires and spokes, use a solution of 1-part Simple Green to 30-parts water — spray onto soiled areas. Wipe immediately with damp cloth to rinse, followed by dry towel — making sure to completely dry the area cleaned. My point is to show that you are supposed to cut the Simple Green with 30 parts of water. MOST people don't do this step. Simple Green (and many other cleaners) are very concentrated. NEVER clean a bicycle with this kind of cleaner without proper dilution. Read labels. Follow directions. Full strength Simple Green has enough butyl solvent to corrode bare aluminum on brake surfaces on wheels and if the wheel is too wet it can actually melt the glue of the rim strip by seeping in the spoke holes. I have seen this at bike shops a lot. The cleaner (if sprayed full strength around bearings) over spray has the potential to break down the grease -- after all it is a degreaser. Always dampen a cloth or sponge in your cleaning solution and wipe down a bike. Don't spray it.

- Q: Are there any limitations to the maximum coil length of aluminum coils?

- The maximum length of aluminum coils is subject to certain limitations. Factors that affect the maximum coil length include the thickness and width of the coil, the strength and tensile properties of the aluminum alloy, the equipment used for coil processing, and the intended application of the coil. One limitation is the strength and ductility of the aluminum alloy. Aluminum alloys with higher strength and lower ductility may have restrictions on the maximum coil length due to the risk of coil breakage or deformation during processing or handling. Another limitation is the coil processing equipment. The maximum coil length is often determined by the size and capabilities of the equipment used for slitting, cutting, or forming the coils. If the equipment has limited capacity or is not designed for longer coils, it may not be able to effectively handle or process longer lengths. The intended application of the coil can also impose limitations. For example, in the automotive industry, there may be restrictions on the maximum coil length based on the size and weight limitations of the vehicles. Moreover, logistical factors such as transportation and storage can also impose limitations. Longer coils may be more challenging to handle, transport, and store, which can increase the risk of damage or pose challenges in terms of logistics and space requirements. Therefore, it is crucial to consider various factors such as alloy properties, equipment capabilities, application requirements, and logistical considerations to determine the practical limitations of coil length for a specific situation, as there is no specific universal limit to the maximum coil length of aluminum coils.

Send your message to us

Aluminum Coils Tampa Fl - Alu Coil for Casting Stock 6-8mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords