Aluminum Led Profiles AA1050 Mill-Finished Aluminum Coils D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA1050 Mill-Finished Aluminum Coils D.C Quality Used for Construction Description

AA1050 Mill-Finished Aluminum Coils D.C Quality Used for Construction has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA1050 Mill-Finished Aluminum Coils D.C Quality Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA1050 Mill-Finished Aluminum Coils D.C Quality Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

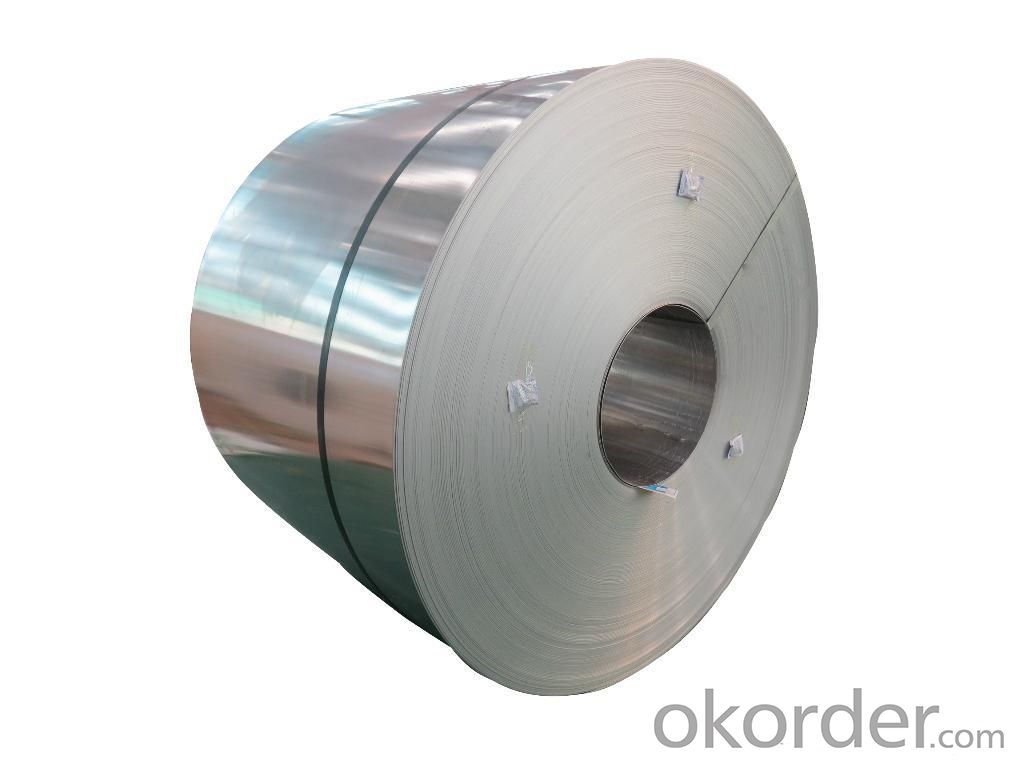

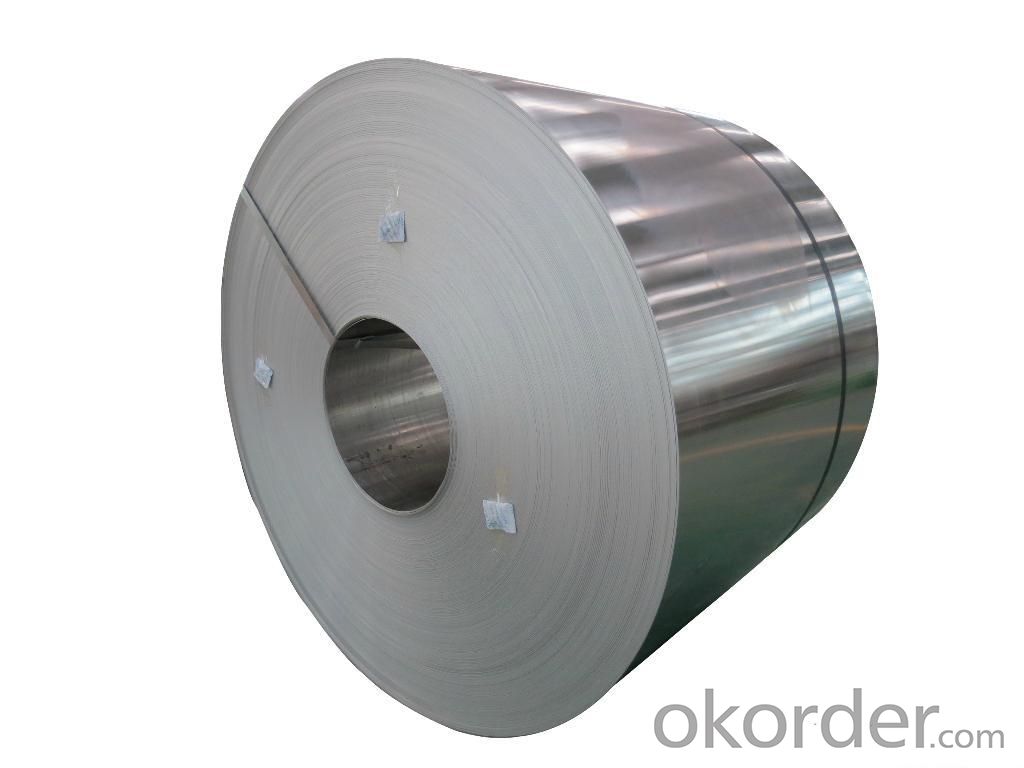

3.AA1050 Mill-Finished Aluminum Coils D.C Quality Used for Construction Images

4.AA1050 Mill-Finished Aluminum Coils D.C Quality Used for Construction Specification

Alloy | AA1050 |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA1050 Mill-Finished Aluminum Coils D.C Quality Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA1050 Mill-Finished Aluminum Coils D.C Quality Used for Construction.

B.When will you deliver the products?

AA1050 Mill-Finished Aluminum Coils D.C Quality Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: Are aluminum profiles suitable for use in pharmaceutical manufacturing?

- Yes, aluminum profiles are suitable for use in pharmaceutical manufacturing. They are lightweight, corrosion-resistant, and easily sanitized, making them ideal for maintaining high levels of cleanliness and meeting the stringent requirements of pharmaceutical manufacturing processes. Additionally, aluminum profiles offer excellent strength and durability, ensuring the safety and reliability of pharmaceutical equipment.

- Q: What are the ten brands of aluminum alloy profiles?

- Top ten list of Chinese aluminum profiles Enterprises1 、 aluminum material(China Aluminum Group, China's top ten aluminum enterprises, central management of large state-owned enterprises)2 - Asia - South Asia(China famous trademark, China famous brand, China aluminum profile enterprise ten, Guangdong Asia Aluminum Factory Co., Ltd.)3, the United States and aluminum(A Well-Known Trademark in China, China brand, China aluminum enterprise ten, Guangdong Jianmei Aluminum Profile Factory Co., Ltd.)4, South South aluminum(China famous brand, Guangdong famous brand, Guangdong famous brand product, Guangdong south south Aluminum Industry Co., Ltd.)5, Zhong Wang aluminum(China famous brand, China famous brand, Liaoning famous brand product, China Zhong Wang Holdings Limited)6, Hing Fat aluminum(China brand, A Well-Known Trademark in China, China aluminum enterprise ten, Xingfa Aluminum Holdings Limited)7, pillars of aluminum(listed companies, Chinese famous brands, China's well-known trademarks, China's aluminum enterprises ten, Zhejiang pillars, new materials, Limited by Share Ltd)8 、 Nanshan aluminum material(China famous brand, China well-known trademark, ten aluminum profile enterprises in China, Shandong Nanshan aluminum & Limited by Share Ltd)9, the court aluminum profiles(China's well known trademark, China's top ten aluminum enterprises, Polytron Technologies Inc, Shanghai aluminum Fair)10, Albert aluminum(China famous brand, Guangdong famous brand, Guangdong famous brand product, Guangdong Weiye aluminium factory Co., Ltd.)

- Q: This question asks about the various standards and specifications that govern the manufacturing and quality of aluminum profiles.

- <p>Aluminum profiles are governed by a variety of standards and specifications that ensure quality and consistency. These include international standards such as ISO 7599, which specifies tolerances for aluminum profiles, and ASTM B221, which covers aluminum and aluminum-alloy extruded bars, rods, and profiles. National standards like the European EN 573 or the Chinese GB/T 6892 also provide guidelines for aluminum profiles. Specifications cover dimensions, mechanical properties, surface finishes, and tolerances. Each standard may have specific requirements for different types of profiles, such as those used in construction, automotive, or aerospace industries. Compliance with these standards is crucial for ensuring the safety, performance, and reliability of aluminum profiles in various applications.</p>

- Q: Are aluminum profiles suitable for decorative applications?

- Yes, aluminum profiles are suitable for decorative applications. Aluminum is a versatile material that offers several advantages in decorative applications. Firstly, aluminum profiles can be easily shaped and formed into various designs, allowing for endless possibilities in decorative applications. They can be extruded into different shapes, sizes, and patterns, giving designers the freedom to create unique and aesthetically pleasing decorative elements. Moreover, aluminum profiles offer excellent durability and corrosion resistance, making them suitable for both indoor and outdoor decorative applications. Aluminum is known for its ability to resist rust and weathering, ensuring that decorative elements made from aluminum profiles will maintain their appearance for a long time. Additionally, aluminum profiles can be finished in various ways to enhance their decorative appeal. They can be anodized or powder-coated to add color, texture, and protection to the surface. These finishing options allow for customization and the ability to match the profiles with the overall design scheme. Furthermore, aluminum profiles are lightweight yet strong, making them easy to install and handle during the decorative application process. This characteristic also makes them suitable for applications where weight is a consideration, such as in suspended or wall-mounted decorative elements. Lastly, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable, and the production process of aluminum profiles requires considerably less energy compared to other materials. Choosing aluminum profiles for decorative applications aligns with sustainable design principles and contributes to reducing the environmental impact. In conclusion, aluminum profiles are highly suitable for decorative applications due to their versatility, durability, corrosion resistance, customization options, lightweight nature, and sustainability. Whether it's for interior or exterior decorative elements, aluminum profiles offer a wide range of possibilities to enhance the aesthetic appeal of any space.

- Q: What are the different color options for aluminum profiles?

- The different color options for aluminum profiles vary depending on the manufacturer and finish. Some common color options include natural silver, black, white, bronze, and various shades of metallic and anodized finishes.

- Q: Can aluminum profiles be used for retail displays?

- Yes, aluminum profiles can be used for retail displays. Aluminum profiles are lightweight, durable, and can be easily customized to fit various display needs. They provide a sleek and modern look, making them ideal for showcasing products in a retail setting. Additionally, aluminum profiles can be easily assembled, disassembled, and reconfigured, allowing for flexibility and adaptability in creating appealing retail displays.

- Q: Does the profiled bar include aluminum profiles? What are the differences between aluminum and profile?

- In fact, profile and profile now in concept, there is not much difference. Special non conventional means. In fact, the conventional shape shape materials generally have a special name: like bar, sheet, pipe, wire rod, angle, elliptical material and so on. So that the profile is actually refers to the profile.

- Q: Can aluminum profiles be used for soundproofing?

- Yes, aluminum profiles can be used for soundproofing to a certain extent. Aluminum profiles are commonly used in the construction industry for various purposes, including window frames and door frames. When used in soundproofing applications, aluminum profiles can help reduce noise transmission through windows and doors. Aluminum is a lightweight and durable material that can effectively block or dampen sound waves. It has good structural integrity, which allows for the creation of tight seals when installed properly. This helps in reducing sound leakage and improving sound insulation. To enhance soundproofing, aluminum profiles can be combined with other materials like rubber gaskets or weatherstripping, which further improves the sealing properties. Additionally, double or triple glazing with laminated glass can also be used in conjunction with aluminum profiles to provide better sound insulation. However, it is important to note that while aluminum profiles can contribute to soundproofing, they may not provide the same level of sound reduction as other specialized soundproofing materials such as acoustic panels or insulation. The effectiveness of aluminum profiles in soundproofing also depends on factors such as the thickness and quality of the profiles, the design of the window or door system, and the overall construction of the building. In conclusion, while aluminum profiles can help in reducing noise transmission through windows and doors, they should be considered as part of a comprehensive soundproofing strategy rather than the sole solution.

- Q: Are aluminum profiles suitable for interior design applications?

- Aluminum profiles are appropriate for interior design applications, offering numerous benefits in this field. Firstly, they are lightweight yet sturdy, facilitating easy installation and working processes. This grants designers the freedom to create intricate shapes and structures, adding flexibility to their designs. Moreover, aluminum possesses exceptional durability and resistance to rust and corrosion. Consequently, it is ideal for a wide range of interior design applications, including door frames, window frames, partitions, cabinets, and furniture. The ability of aluminum profiles to withstand wear and tear guarantees longevity and reduces maintenance requirements. Furthermore, aluminum profiles provide customization options and can be finished in various ways. They can be powder-coated or anodized, allowing for the achievement of different colors and textures. This versatility enhances the design possibilities and enables the creation of unique and aesthetically pleasing interiors. Additionally, aluminum is an environmentally friendly material that supports sustainability. It is highly recyclable and requires significantly less energy for production compared to other metals. Consequently, it aligns with the growing trend of eco-conscious design, making it a responsible choice for interior design applications. In conclusion, aluminum profiles are unquestionably suitable for interior design purposes. Their lightweight nature, durability, customization options, and sustainability aspects make them an ideal choice for creating functional and visually appealing interiors.

- Q: This question asks about the various methods employed in the production of aluminum profiles, which are long, extruded shapes made from aluminum.

- <p>Aluminum profiles are manufactured using several processes, primarily extrusion, which involves forcing aluminum through a die to create specific shapes. Other processes include casting, where aluminum is poured into molds, and rolling, used to create flat sheets or plates. Machining processes like cutting, drilling, and milling are also used for further shaping and finishing. Additionally, aluminum profiles can be fabricated through bending, which shapes the material into curves or angles, and welding, which joins pieces together. Surface treatments like anodizing, painting, or powder coating are also applied to enhance appearance and durability.</p>

Send your message to us

Aluminum Led Profiles AA1050 Mill-Finished Aluminum Coils D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords