Aluminum Siding Profiles - AA3XXX Mill-Finished Aluminum Coils D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

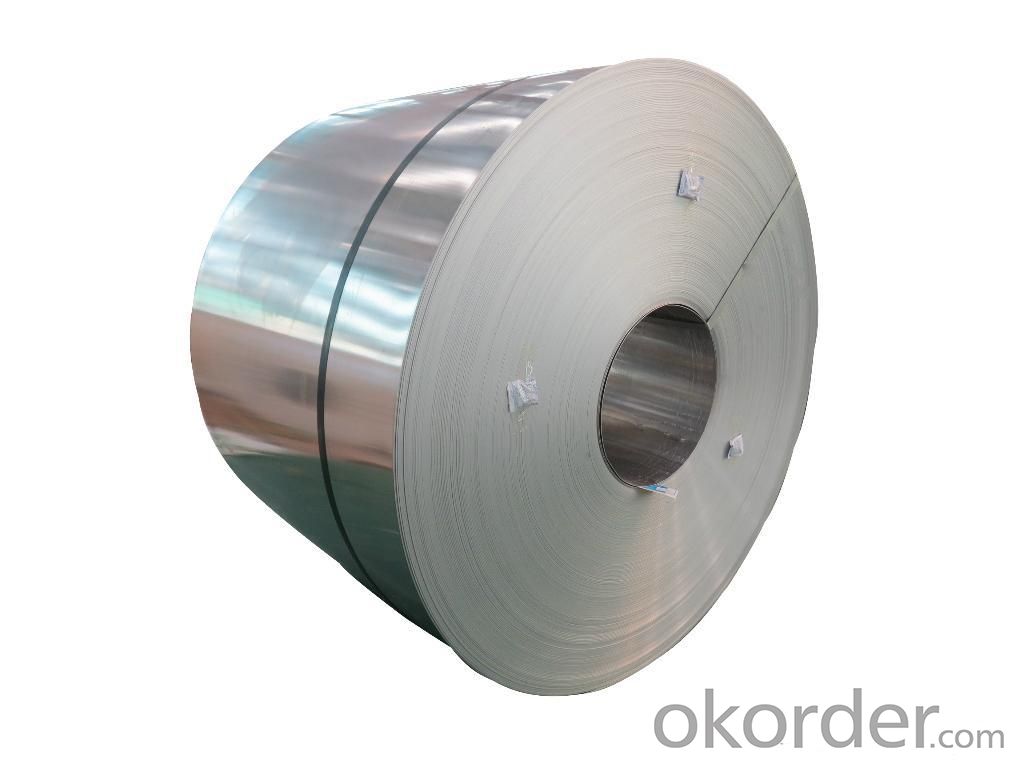

1.Structure of AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction Description

AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction Images

4.AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction Specification

Alloy | AA3xxx (AA3003, AA3105 etc.) |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction.

B.When will you deliver the products?

AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: Is it possible to utilize aluminum profiles in the construction or structure of commercial buildings and factories?

- <p>Yes, aluminum profiles are commonly used in commercial buildings and factories due to their strength, durability, and lightweight properties. They are ideal for constructing frameworks, window and door frames, and support structures. The corrosion resistance of aluminum also makes it suitable for industrial environments where exposure to harsh chemicals or weather conditions is a concern. Additionally, aluminum profiles are easy to maintain and can be recycled, contributing to the sustainability of construction projects.</p>

- Q: Can aluminum profiles be used for display cases or cabinets?

- Yes, aluminum profiles can definitely be used for display cases or cabinets. Aluminum profiles are lightweight, durable, and have a sleek, modern appearance which makes them a popular choice for displaying products or storing items in cabinets. They can be easily customized and come in various sizes and shapes to meet specific design requirements. Additionally, aluminum profiles are corrosion-resistant, making them suitable for both indoor and outdoor applications. They also offer excellent thermal conductivity, which can be beneficial for controlling temperature in display cases or cabinets. Overall, aluminum profiles provide a versatile and attractive solution for creating display cases or cabinets.

- Q: What are the different shapes available for aluminum profiles?

- Aluminum profiles come in a variety of shapes, each designed to cater to different needs and applications. Some commonly used shapes include T-Slot profiles, square profiles, rectangular profiles, round profiles, L-shaped profiles, U-shaped profiles, and custom profiles. T-Slot profiles are widely used in construction, robotics, and industrial applications due to their easy assembly and integration of other components. Square profiles provide excellent strength and rigidity, making them ideal for structural applications like building frames and support structures. Rectangular profiles offer versatility and can be used in enclosures, partitions, and conveyor systems. Round profiles are commonly utilized for applications that require a smooth and aesthetically pleasing finish, such as architectural purposes. L-shaped profiles, on the other hand, are often used for corner joints, edges, and brackets, providing structural support and stability. U-shaped profiles resemble an open channel and are frequently used to house and guide cables, wires, or other components. In addition to these standard shapes, aluminum profiles can also be custom-designed and manufactured to meet specific project requirements. This allows for greater flexibility in ensuring that the profiles perfectly fit the intended application. Overall, the availability of different shapes for aluminum profiles empowers engineers, designers, and manufacturers to choose the most suitable shape for their specific needs. This ensures optimal performance, functionality, and aesthetics.

- Q: Can aluminum profiles be utilized for creating distinctive architectural designs, and if yes, what are the ways to achieve this?

- <p>Yes, aluminum profiles can be used to create unique architectural designs. They are favored for their strength, light weight, and corrosion resistance, which allow for innovative and sustainable building solutions. Architects can use aluminum profiles in various ways: as structural components in curtain walls, as decorative elements in facades, or as supports in roof structures. The profiles can be custom-cut and shaped to fit specific design requirements, and they can be combined with glass or other materials to create a harmonious blend of aesthetics and functionality. Additionally, aluminum's recyclability and low maintenance make it an environmentally friendly choice for architectural projects.</p>

- Q: What does T6 mean in aluminum alloy sections?

- The aluminum alloy heat treatment process of the broken bridge aluminum profile: the specific content is as follows:T6 is the deformation of Aluminum Alloy (distinguished from casting Aluminum Alloy) a heat treatment process, is "solid solution treatment (for steel in this process is called" quenching ", everyone should be very familiar with) + artificial aging process", of which the main factor is the solid solution temperature, quenching rate (determined by the quenching medium) and the aging temperature, holding time, time series (an aging or ageing).For different alloys, the same heat treatment code, such as T6, contains values that vary from one factor to another.This process is distinguished from what is commonly known as an annealing process.This process is the key to solving the problems of strength, plasticity, reasonable collocation (high strength and sufficient plasticity) and corrosion resistance.Without deformation of alloy Txxx processing, is absolutely can not be used as a structural material, will be mine, so please rest assured that your car frame (if not from the black hearted miners workshop) must have been processed.2014 aluminum alloy commonly used heat treatment state code has T6, T62, T651 (E), different product shape processing process is slightly different.My MOSSO car shelf is 7005 alloy, the usual process is T53 (V), do not write above also know.Handlebar and handlebar immediately 6061 aluminum alloy T6The above aluminum alloys are all foreign brands

- Q: Are there various ways to install aluminum profiles?

- <p>Yes, aluminum profiles can be installed using different methods. Common installation techniques include direct fastening with screws or bolts, using adhesives or sealants, and employing clip or channel systems. The choice of method depends on the specific application, load-bearing requirements, and aesthetic considerations. Some methods may provide quicker installation, while others might offer better structural integrity or visual appeal. It's important to consult with a professional or follow manufacturer guidelines to ensure the proper installation method is used for the intended application.</p>

- Q: Are aluminum profiles suitable for signage and advertising displays?

- Yes, aluminum profiles are suitable for signage and advertising displays. They are lightweight, durable, and corrosion-resistant, making them ideal for indoor and outdoor applications. Aluminum profiles can be easily customized and fabricated to create various shapes and sizes, allowing for versatile and eye-catching signage and advertising displays. Additionally, they offer a sleek and modern appearance, enhancing the overall aesthetics of the display.

- Q: What is the limitation of aluminum bending

- Because the aging hardness will increase, and then take the bend, one is not easy to bend, and the other out of the bend, the effect is not good. So generally speaking like hanging rail is the first bend reaging.

- Q: What is the nitriding process of aluminum extrusion die?

- The principle of nitridation:Gas nitrocarburizing, that is gas nitrocarburizing, refers to low temperature nitrocarburizing based on gas nitriding and carburizing. Commonly used media have 50% ammonia, +50% endothermic gas (Nitemper method); 35%-50% ammonia, +50-60% exothermic gas (Nitroc method) and ammonia through the drip ethanol or formamide and so on. In soft nitriding, because of the high solubility of carbon atoms in the epsilon phase, the soft nitrided surface is a common compound of carbon and nitrogen, which is good in toughness and wear resistant.In the process of gas nitrocarburizing, due to the extremely low solubility of carbon atoms, it quickly reaches saturation state and precipitates many super micro cementite points. These cementite particles, as the core of the crystallization of nitrides, contribute to the formation of nitrides. When the surface nitrogen concentration reaches a certain level, the epsilon phase is formed, while the carbon solubility of the epsilon phase is very high, which in turn accelerates the dissolution of carbon.After gas nitrocarburizing, its structure is composed of epsilon phase, gamma phase and nitrogen containing cementite Fe3 (C, N), carbon will reduce the diffusion rate of nitrogen, so the thermal stress and the stress of the tissue are hard, the nitriding is large and the layer is thinner. But at the same time, because the soft nitride layer does not exist. Therefore, the nitride layer, better toughness than hard nitriding

- Q: How do aluminum profiles perform in fire-resistant structures?

- Fire-resistant structures have found aluminum profiles to be highly effective. The inherent properties of aluminum profiles make them excellent for fire resistance and they are widely used in applications where fire protection is crucial. One of the main advantages of aluminum profiles in fire-resistant structures is their ability to maintain their structural integrity even under high temperatures. Aluminum has a high melting point of approximately 660 degrees Celsius, making it highly resistant to heat. This characteristic ensures that the profiles retain their shape and strength during a fire, thereby ensuring the overall stability and safety of the structure. Additionally, aluminum profiles have low thermal conductivity, meaning they do not easily transfer heat. This property helps to contain the spread of fire and minimize its impact on the surrounding areas. By acting as a barrier against heat transfer, aluminum profiles effectively compartmentalize the fire, preventing rapid spread and providing occupants with more time to evacuate. Moreover, aluminum profiles are lightweight and durable, further contributing to their suitability in fire-resistant structures. Their lightweight nature makes them easy to handle during construction and reduces the overall weight of the structure. The durability of aluminum ensures that it can withstand the test of time and maintain its fire-resistant properties throughout the lifespan of the structure. Furthermore, aluminum profiles can be treated with special coatings or finishes to enhance their fire resistance. These additional layers of protection further delay the ignition of the aluminum and improve its fire performance. Overall, aluminum profiles are a reliable and efficient choice for fire-resistant structures. They offer exceptional fire resistance, heat containment, and durability, making them a preferred option for architects, engineers, and builders who prioritize fire safety in their designs.

Send your message to us

Aluminum Siding Profiles - AA3XXX Mill-Finished Aluminum Coils D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords