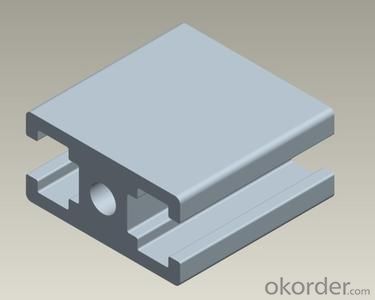

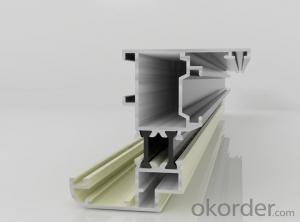

Aluminum Heat Sink Extrusion Profiles for Decoration

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Alu Profile:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Guangzhou/Shenzhen port

4. Delivery time?

15-20 days after client’s deposit

- Q: What are the different colors and finishes available for aluminum profiles?

- There are various colors and finishes available for aluminum profiles, including but not limited to natural (mill finish), anodized, powder-coated, and wood-grain finishes. These finishes can be applied in a wide range of colors, allowing for customization and versatility in design.

- Q: This question asks for an overview of the various types of aluminum profiles that are utilized in the construction of interior partitions and ceilings.

- <p>Aluminum profiles for interior partitions and ceilings come in various types, each serving specific purposes and functions. Common types include: 1. U-Channel profiles, used for creating the framework of ceilings and partitions. 2. T-profiles, often used as a cover for the joints between panels. 3. H-profiles, which are used as main beams in ceiling systems. 4. Angle profiles, used for corner connections and support. 5. Flat bar profiles, used for decorative or functional purposes in ceilings and partitions. 6. Box profiles, which can be used for both structural and aesthetic applications. 7. Special profiles, designed for specific applications such as lighting fixtures or air conditioning ducts. These profiles are chosen based on the design requirements, load-bearing needs, and aesthetic preferences for the project.</p>

- Q: Are aluminum profiles suitable for cleanroom applications?

- Indeed, cleanroom applications can benefit from the use of aluminum profiles. Due to its lightweight and durable nature, aluminum proves to be an ideal material that resists corrosion, which is crucial in environments where cleanliness and hygiene are of utmost importance. The ease of cleaning and sterilizing aluminum profiles, along with their smooth surface that prevents the accumulation of dirt, dust, or particles, ensures the preservation of a contamination-free atmosphere within cleanrooms. Moreover, aluminum profiles can be tailored to fit specific requirements and effortlessly integrated with other cleanroom elements, such as panels and doors, resulting in a seamless and hygienic environment. Ultimately, aluminum profiles possess the necessary strength, cleanliness, and adaptability essential for cleanroom applications.

- Q: Is it possible to recycle aluminum profiles and incorporate them into new construction projects?

- <p>Yes, aluminum profiles can be recycled and reused in new building projects. Aluminum is highly recyclable, and the recycling process is energy-efficient, requiring only 5% of the energy needed to produce new aluminum. Recycled aluminum maintains its properties, making it suitable for various applications in construction. This practice not only conserves resources but also reduces waste and environmental impact.</p>

- Q: What are aluminum profiles used for?

- Aluminum profiles are used for a wide range of applications across various industries. One of the primary uses of aluminum profiles is in construction and architecture. They are commonly used in the framing of windows, doors, and curtain walls due to their lightweight yet sturdy nature. Aluminum profiles are also used in the construction of modular structures, such as exhibition stands, trade show booths, and temporary shelters. In the automotive industry, aluminum profiles are utilized for manufacturing components such as vehicle frames, roof rails, and trim parts. The lightweight properties of aluminum make it an ideal choice for improving fuel efficiency and reducing overall vehicle weight. Another significant application of aluminum profiles is in the production of industrial machinery and equipment. These profiles are used for constructing machine frames, conveyor systems, and assembly lines. The versatility of aluminum profiles allows for easy customization and modification to meet specific industrial requirements. Additionally, aluminum profiles find extensive use in the manufacturing of furniture and interior design. They are widely employed for constructing shelving units, workstations, display cabinets, and partitions due to their aesthetics, durability, and corrosion resistance. Furthermore, aluminum profiles are extensively used in the electrical and electronics industry. They are used for manufacturing heat sinks, enclosures, and mounting brackets. The excellent thermal conductivity of aluminum helps dissipate heat effectively, making it an ideal choice for electronic devices. Overall, the versatility, lightweight nature, corrosion resistance, and ease of customization make aluminum profiles highly sought after in numerous industries, offering a wide range of applications in construction, automotive, machinery, furniture, and electronics sectors.

- Q: How is the tonnage of aluminum profile extrusion machine calculated? Do you have any formulas? For example, 30*60 industrial profiles, the need for a large tonnage of extrusion machine can be done?

- This section is almost the same as a 1500-2000 ton extruder.In general, the extrusion ratio of 6063 profiles will be controlled at around 30-150,That is, the section of rice weight / casting rod of rice weight, or section section area / aluminum bar cross-sectional area.

- Q: What are the different machining options available for aluminum profiles?

- There are several machining options available for aluminum profiles, including milling, drilling, tapping, turning, and sawing. These processes can be used to create various shapes, sizes, and features on the aluminum profiles, allowing for customization and precise fabrication. Additionally, advanced techniques such as CNC machining and laser cutting can also be employed for more complex and intricate designs.

- Q: This question asks for a list of various aluminum profiles that are specifically designed or used for roofing systems in regions with cold climates.

- <p>In cold climates, aluminum profiles for roofing systems are selected for their durability, strength, and resistance to harsh weather conditions. Common types include: 1. Standing Seam Profiles: These are popular for their weather-tightness and resistance to snow and ice. 2. Trapezoidal Profiles: Known for their strength and ability to handle heavy snow loads. 3. Box Rib Profiles: These provide excellent structural integrity and are suitable for areas with high wind uplift. 4. Snap-Lock Profiles: Easy to install and offer good resistance to snow and ice. 5. Corrugated Profiles: Provide a traditional look while being cost-effective and offering good drainage. 6. Panel Rib Profiles: These are designed for long spans and can withstand heavy snowfall. Each profile has specific applications and advantages, and the choice depends on the specific roofing requirements and local climate conditions.</p>

- Q: Are aluminum profiles suitable for food processing or storage facilities?

- Yes, aluminum profiles are suitable for food processing or storage facilities. Aluminum is a highly versatile material that offers several advantages in these environments. Firstly, aluminum is corrosion-resistant, ensuring that it remains unaffected by moisture, food acids, or cleaning agents commonly used in food facilities. This makes it ideal for use in areas where hygiene and cleanliness are crucial. Secondly, aluminum profiles are lightweight yet sturdy, making them easy to handle and install. This is especially beneficial in food processing facilities where regular equipment maintenance and reconfigurations are required. Additionally, aluminum is a non-toxic material, ensuring that it does not contaminate food products during processing or storage. It is also an excellent conductor of heat, allowing for efficient temperature control in processing facilities. Furthermore, aluminum profiles can be easily cleaned and sanitized, reducing the risk of bacterial growth and ensuring compliance with food safety regulations. Overall, the durability, corrosion resistance, lightweight nature, non-toxicity, and ease of maintenance make aluminum profiles an excellent choice for food processing or storage facilities.

- Q: Can aluminum profiles be used in the production of medical devices?

- Yes, aluminum profiles can be used in the production of medical devices. Aluminum is a lightweight and corrosion-resistant material that offers several advantages for medical applications. It can be easily machined, formed, and welded into various shapes and sizes, making it suitable for creating precise and complex components required in medical devices. Aluminum profiles also have excellent conductivity properties, which is essential for devices that require electrical connections. Additionally, aluminum is non-toxic, non-magnetic, and does not release harmful substances, making it safe for use in medical settings. It is widely used in the production of medical devices such as surgical instruments, hospital bed frames, wheelchair components, IV stands, and many others.

Send your message to us

Aluminum Heat Sink Extrusion Profiles for Decoration

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords