Aluminum Frame Extrusion Profiles for Light Application - Best Price and Quality Aluminium Circles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Circle for Light Application Best Price and Best Quality Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Circle for Light Application Best Price and Best Quality:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

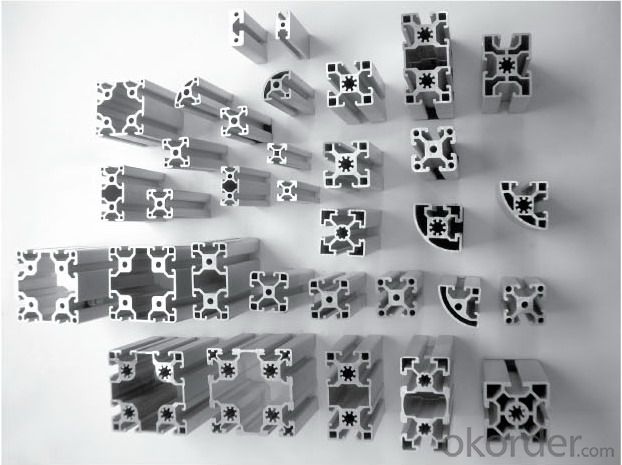

Images of theAluminium Circle for Light Application Best Price and Best Quality:

Aluminium Circle for Light Application Best Price and Best Quality Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: This question asks whether aluminum profiles are susceptible to damage from moisture and corrosion.

- <p>Aluminum profiles are generally resistant to moisture and corrosion due to their natural protective oxide layer. However, this resistance can be compromised in certain conditions. For instance, in highly corrosive environments or when exposed to aggressive chemicals, the protective layer may not be sufficient. Additionally, if the aluminum is not properly sealed or coated, it can still be affected by moisture over time. It's important to maintain the integrity of the protective layer and consider the specific environment when using aluminum profiles to ensure their longevity and resistance to corrosion.</p>

- Q: How do you prevent discoloration or fading of aluminum profiles?

- To prevent discoloration or fading of aluminum profiles, there are several steps that can be taken: 1. Regular cleaning: It is essential to regularly clean aluminum profiles to remove any dirt, dust, or contaminants that can cause discoloration or fading. This can be done using a mild detergent or a specialized aluminum cleaner, followed by rinsing with clean water. 2. Avoid abrasive cleaners: Harsh or abrasive cleaners can cause damage to the surface of aluminum profiles, leading to discoloration or fading. It is important to use gentle cleaning products specifically designed for aluminum. 3. Protective coatings: Applying a protective coating to the surface of aluminum profiles can help prevent discoloration and fading. There are different types of coatings available, such as clear coats or anodizing, that provide a protective barrier against environmental factors. 4. Avoid exposure to harsh elements: Aluminum profiles should be protected from prolonged exposure to harsh elements like direct sunlight, extreme temperatures, or chemicals. These factors can accelerate the discoloration or fading process. If the profiles are installed outdoors, consider providing adequate shading or protective covers to minimize exposure. 5. Regular maintenance: Regular inspection and maintenance of aluminum profiles can help identify any early signs of discoloration or fading. Promptly addressing any issues, such as scratches or surface damage, can prevent further deterioration. 6. Proper storage: If aluminum profiles are not immediately installed, it is important to store them in a dry and well-ventilated area, away from moisture or direct sunlight. Proper storage can help maintain the integrity of the profiles and prevent premature discoloration or fading. By following these preventive measures, it is possible to prolong the lifespan and maintain the aesthetic appeal of aluminum profiles, minimizing the risk of discoloration or fading.

- Q: Inquire about the various uses of aluminum profiles within the field of architecture.

- <p>Aluminum profiles have a wide range of applications in architecture due to their strength, durability, and lightweight properties. They are commonly used in curtain walls, which are the exterior coverings of buildings, providing both aesthetic appeal and structural integrity. Aluminum profiles are also utilized in window and door frames for their resistance to corrosion and ability to withstand various weather conditions. They are employed in structural glazing to hold glass in place securely. Furthermore, aluminum profiles are used in sun shading systems to control the amount of sunlight entering a building, enhancing energy efficiency. They are also found in handrails, balustrades, and other safety features for their strength and low maintenance requirements. Overall, aluminum profiles contribute to the sustainability and modern design of architectural projects.</p>

- Q: Can aluminum profiles be used for solar panel mounting systems?

- Yes, aluminum profiles can be used for solar panel mounting systems. Aluminum is a popular choice for solar panel mounting systems due to its numerous advantages. Firstly, aluminum is lightweight, making it easier to handle and install. This is especially important when considering the weight that solar panels can add to a structure. Secondly, aluminum is corrosion-resistant, which is crucial as solar panel mounting systems are exposed to various weather conditions. Additionally, aluminum is a durable material that can withstand high winds, snow loads, and other environmental factors. Furthermore, aluminum profiles can be easily customized and fabricated to fit specific project requirements. They are available in various sizes and shapes, allowing for flexibility in design and installation. Overall, aluminum profiles provide a reliable and efficient solution for solar panel mounting systems.

- Q: Can aluminum profiles be used in the construction of curtain walls?

- Yes, aluminum profiles can be commonly used in the construction of curtain walls. Aluminum offers durability, lightweight properties, and excellent corrosion resistance, making it a popular choice for curtain wall systems. Additionally, aluminum profiles can be easily fabricated and installed, allowing for flexibility in design and efficient construction processes.

- Q: Are aluminum profiles suitable for architectural design that demands a distinctive visual appeal?

- <p>Yes, aluminum profiles can be effectively utilized in architectural design to achieve a unique aesthetic look. They offer versatility in terms of shape and size, allowing for the creation of distinctive designs. Their lightweight nature and high strength make them ideal for various architectural applications. Additionally, aluminum profiles can be easily finished or coated to match specific design requirements, enhancing their visual appeal. Their durability and resistance to corrosion also make them a sustainable choice for long-lasting architectural projects.</p>

- Q: Are aluminum profiles suitable for constructing energy-efficient buildings?

- <p>Yes, aluminum profiles can be used to create energy-efficient building designs. They are lightweight, strong, and have excellent thermal conductivity, which can be utilized to design structures with reduced heat transfer, thereby improving energy efficiency. Aluminum profiles can also be used in combination with insulating materials to enhance thermal insulation. Their recyclability and low maintenance requirements contribute to sustainability, further supporting energy-efficient construction practices.</p>

- Q: What are the different bending machines or tools used for aluminum profiles?

- There are several bending machines and tools that are commonly used for aluminum profiles. These tools are designed to manipulate aluminum profiles into various shapes and angles to meet specific project requirements. 1. Manual Tube Bender: This is a hand-operated bending tool that is commonly used for smaller aluminum profiles. It consists of a lever and a bending shoe that is used to bend the profile manually. 2. Hydraulic Tube Bender: This machine is equipped with hydraulic power to bend larger and thicker aluminum profiles. It offers more precision and control compared to manual benders, making it suitable for industrial applications. 3. CNC Tube Bending Machine: This is a computer-controlled machine that uses a combination of hydraulic power and computer programming to accurately bend aluminum profiles. It can produce complex and precise bends, making it ideal for high-volume production and intricate designs. 4. Roll Bending Machine: This machine is specifically designed for bending aluminum profiles into curved shapes. It consists of three rolls, with the profile passing through the middle roll while the other two rolls apply pressure to bend it into the desired curve. 5. Mandrel Bender: This tool is used for bending aluminum profiles without deforming or collapsing the inner diameter. It uses a mandrel (a rod inserted into the profile) to support the inner wall during the bending process, ensuring a smooth and consistent bend. 6. Rotary Draw Bender: This machine uses a combination of bending dies and a rotating arm to produce accurate and repeatable bends in aluminum profiles. It is commonly used for bending tubes and pipes, but can also be adapted for aluminum profiles. These bending machines and tools offer different levels of precision, control, and production capacity, allowing manufacturers and fabricators to choose the most suitable option based on their specific needs and requirements.

- Q: This question asks about the typical applications of aluminum profiles within the field of architectural design.

- <p>Aluminum profiles are commonly used in building design for various structural and aesthetic purposes. They are utilized in curtain walls, window frames, and door systems for their strength and lightweight properties. Additionally, aluminum profiles are employed in the construction of balconies, handrails, and sunshades due to their durability and resistance to corrosion. They are also used in interior design for creating partition walls, ceiling systems, and decorative elements. The versatility of aluminum profiles allows them to be easily adapted to different architectural styles and requirements, making them a popular choice in modern construction.</p>

- Q: What are the various standards and regulations governing the use of aluminum profiles in construction?

- <p>Aluminum profiles in construction are governed by a variety of standards and regulations that ensure their quality, safety, and performance. These include ISO standards such as ISO 7039 for anodized aluminum and ISO 9001 for quality management systems. National standards like ASTM B221 in the USA and EN 755 in Europe specify mechanical properties and chemical composition. Building codes such as the International Building Code (IBC) and Eurocode 9 also provide guidelines for the use of aluminum in construction. Additionally, there are specific regulations for fire resistance, sustainability, and environmental impact, like the European CE marking for construction products. Compliance with these standards is crucial for manufacturers and builders to ensure the reliability and safety of aluminum profiles used in construction projects.</p>

Send your message to us

Aluminum Frame Extrusion Profiles for Light Application - Best Price and Quality Aluminium Circles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords