Aluminum Foil Facing Flexible Ducts and Bubble Foil AL+PET+LDPE AL+PET AL+PET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Aluminum Foil Mylar Description:

The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

2.Main Features of the Aluminum foil Mylar:

• High manufacturing accuracy

• Small inertia resistance

• High strength

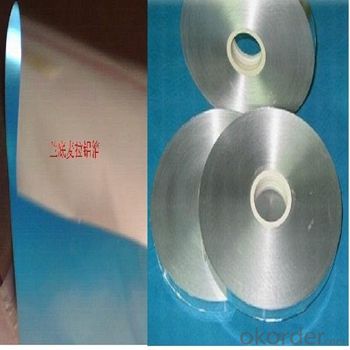

3.Aluminum Foil Mylar Images

4.Aluminum Foil Mylar Specification

TYPICAL PHYSICAL PROPERTIES:

Name:AL+LDPE | |||

Structure | Thickness(mic) | Weight(g/m2) | Yield(m2/kg) |

AL7+ LDPE12 | 21mic | 36 | |

AL7+ LDPE15 | 24 mic | 39 | |

AL9+ LDPE12 | 23mic | 43 | 23 |

AL9 +LDPE15 | 26mic | 48 | 21 |

AL9 +LDPE19 | 30mic | 54 | 19 |

AL9 +LDPE23 | 34mic | 60 | 17 |

AL12 +LDPE12 | 26mic | 52 | 19 |

AL12 +LDPE15 | 29mic | 56 | 18 |

AL12 +LDPE19 | 33mic | 62 | 16 |

AL12 +LDPE23 | 37mic | 67 | 15 |

AL12 +LDPE36 | 50mic | 87 | 12 |

AL15 +LDPE19 | 36mic | 70 | 14 |

AL25 +LDPE12 | 39mic | 87 | 12 |

AL40 +LDPE36 | 78mic | 161 | 6 |

AL50 +LDPE12 | 64mic | 154 | 6 |

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

- Q: Is it possible for aluminum foil facing to induce allergic reactions in certain individuals?

- <p>Yes, aluminum foil facing can cause allergic reactions in some people. Aluminum is a common allergen, and individuals with a sensitivity to it may experience contact dermatitis or other allergic responses when exposed to aluminum-containing products. Symptoms can include redness, itching, and rashes. People with a known allergy to aluminum should avoid direct skin contact with aluminum foil and products containing aluminum.</p>

- Q: The user is asking if they can reuse their old aluminum foil facing to create new ones once it becomes worn out.

- <p>No, you cannot create new aluminum foil facings from old, worn-out ones. Aluminum foil facings are typically made from a specific type of aluminum that is bonded to a substrate. Once it wears out, the aluminum layer is compromised and cannot be reused to make new facings. Recycling old aluminum foil is the best option to reduce waste and conserve resources. You can recycle aluminum foil, which will then be processed and turned into new aluminum products.</p>

- Q: This question asks for instructions on how to clean aluminum foil facing after it has been used in cooking or baking.

- <p>To clean aluminum foil facing after use, first let it cool down to avoid burns. Then, gently scrape off any food residue with a spatula or the edge of a knife. For stubborn stains, mix a solution of warm water and dish soap, and wipe the surface with a soft cloth or sponge. Rinse with clean water and dry thoroughly. For baked-on food, you can use a plastic scraper or an old toothbrush to gently remove it. Avoid using abrasive materials that could scratch the surface. Regular cleaning will help maintain the integrity and appearance of your aluminum foil facing.</p>

- Q: Is it possible to use aluminum foil with a facing layer to create a pie crust or tart crust?

- <p>Using aluminum foil facing to make a pie crust or tart crust is not recommended. Aluminum foil is not designed for baking and can react with acidic foods, potentially releasing harmful substances. Additionally, it won't provide the same texture or structure as a traditional pie crust. Instead, use materials specifically designed for baking, such as pie dough, tart shells, or parchment paper, which are safe and designed to withstand high temperatures without compromising the taste or quality of your baked goods.</p>

- Q: What are the potential health risks associated with cooking food using aluminum foil?

- <p>Cooking with aluminum foil can potentially lead to the leaching of aluminum into the food, which may have health implications. While the body naturally eliminates small amounts of aluminum, excessive intake can be harmful. Aluminum has been linked to neurological disorders, including Alzheimer's disease, although the connection is not definitively proven. It's also important to note that the amount of aluminum that leaches into food during cooking is generally considered to be low. However, for those concerned about aluminum exposure, it's advisable to minimize the use of aluminum foil in cooking, especially for acidic foods which can increase the rate of aluminum leaching.</p>

- Q: Is it possible to use aluminum foil with a facing layer to create a sandwich?

- <p>Using aluminum foil facing to make a sandwich is not recommended. Aluminum foil is not designed for direct food contact, especially when heated, as it can leach aluminum into the food, which is potentially harmful. Instead, use materials specifically designed for food contact, such as wax paper, parchment paper, or plastic wrap, which are safe for contact with food and can withstand the temperatures involved in making a sandwich.</p>

- Q: What are the potential health hazards linked to cooking with aluminum foil?

- <p>Cooking with aluminum foil is generally considered safe, but there are some potential health risks. Aluminum can leach into food, especially when it comes into contact with acidic or salty foods at high temperatures. This could lead to increased aluminum intake, which has been linked to neurological disorders like Alzheimer's disease, although more research is needed to establish a definitive link. Additionally, aluminum foil can cause burns or injuries if not handled properly. It's important to use foil responsibly, avoiding direct contact with food when possible, and to follow proper food safety guidelines.</p>

- Q: Can aluminum foil be used as a material for crafting a pot holder or pot lid holder?

- <p>While aluminum foil is heat resistant to a certain extent, it is not recommended for making a pot holder or pot lid holder due to its low melting point and potential to conduct heat, which could lead to burns or damage to the foil. Instead, consider materials designed for heat resistance such as silicone, fabric with heat-resistant properties, or insulated materials specifically made for kitchen use. These materials are safer and more effective for handling hot pots and lids.</p>

- Q: Is it safe and effective to use aluminum foil with a reflective side to wrap vegetables when grilling?

- <p>Yes, you can use aluminum foil facing to wrap vegetables for grilling. Aluminum foil helps to retain moisture and heat, ensuring that the vegetables cook evenly and remain tender. The reflective side of the foil can also help to distribute heat more evenly. However, be cautious not to let the foil touch the flame directly, as it can cause flare-ups. Make sure to poke some holes in the foil to allow steam to escape and prevent the vegetables from becoming too soggy.</p>

- Q: Is it possible to use aluminum foil as a cooking surface? If yes, what are the methods of using it?

- <p>Yes, aluminum foil can be used for cooking. It's commonly used for wrapping foods to retain moisture and heat, such as when baking potatoes or fish. You can also create a foil packet (en papillote) by placing food in the center of a large piece of foil, seasoning it, and then folding the foil to seal the edges. This method steams the food, keeping it moist. For grilling, use heavy-duty foil to prevent tearing and place food directly on it. Remember, avoid using aluminum foil with acidic foods as it can react and leach aluminum into the food.</p>

Send your message to us

Aluminum Foil Facing Flexible Ducts and Bubble Foil AL+PET+LDPE AL+PET AL+PET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords