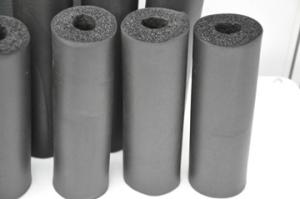

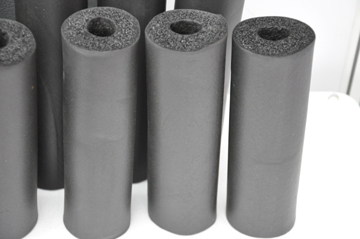

Construction Rubber Foam Insulation Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Air Conditioning Tie Description

Air Conditioning Tie is designed for Air conditioning and used for HVAC system. Air conditioning tie: general and domestic brand air-conditioning manufacturer for cable tie. We can support you with different color like grey and whited or bule.

2.Main Features of Air conditioning tie

our Air conditioning tie with good and environmental quality of the products for the customer design research and development of different types, different colors and different quality of air conditioning products.

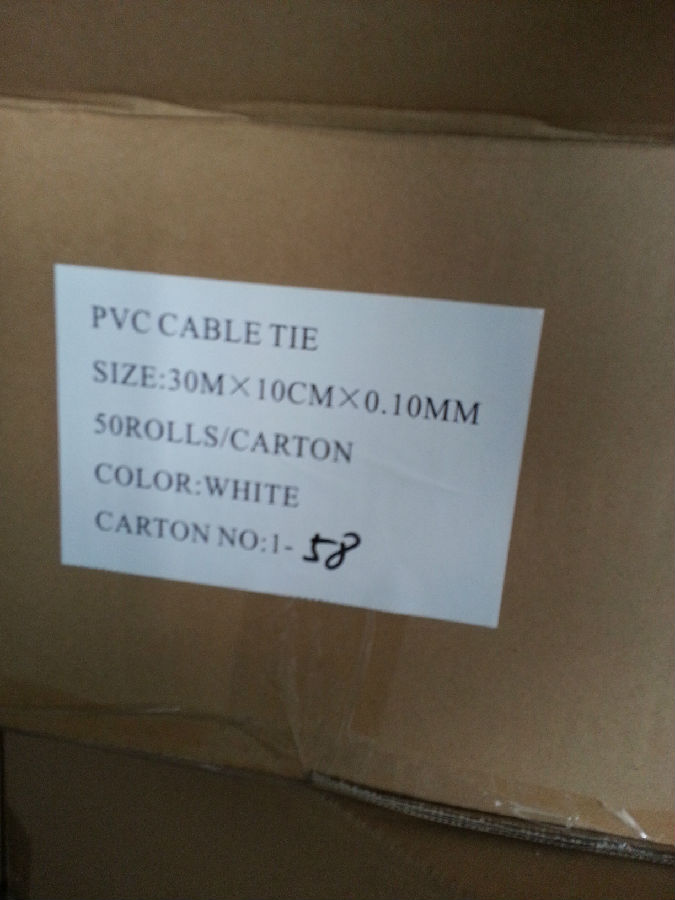

3.Air Conditioning Cable Tie Images

4.Air Conditioning Cable Tie Specification:

0.2 mm * 50 mm * 20 m (thickness * width * length)

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: This question asks about the proper way to store aluminum foil to keep it facing the right way for easy use.

- <p>To store aluminum foil facing the right way, first use up one side completely. Then, fold the remaining foil in half with the shiny side facing out. Place the folded foil back into the box or container, shiny side up. When you need to use it next, the shiny side will be facing you, making it easy to tear off. To keep it flat and wrinkle-free, you can place a piece of cardboard inside the box, or roll it around a clean, empty paper towel tube.</p>

- Q: Can an old aluminum foil facing be repurposed as a pizza stone for baking pizza crusts?

- <p>While it might be tempting to use an old aluminum foil facing as a pizza stone, it's not recommended. A proper pizza stone is made of materials like cordierite or ceramic, which can retain heat well and provide an even cooking surface. Aluminum foil conducts heat quickly and unevenly, which can lead to an unevenly baked crust and may even cause the foil to warp or melt. Instead, invest in a real pizza stone for the best results in baking pizza crusts.</p>

- Q: Is it possible to use aluminum foil facing material to create a bag for storing food items, specifically sandwiches?

- <p>While it is technically possible to use aluminum foil facing to create a makeshift sandwich bag, it is not recommended for long-term food storage. Aluminum foil is not airtight and does not provide a barrier to bacteria or moisture, which can lead to spoilage. For proper food storage, it's better to use food-safe plastic bags or containers designed for this purpose, which offer better protection against contamination and help maintain freshness.</p>

- Q: Is it possible to use aluminum foil with a reflective surface for storing fruits and vegetables?

- <p>Aluminum foil facing can be used for storing fruits and vegetables, but it's not the best choice. Aluminum foil is not breathable and can cause condensation, leading to spoilage. It's better to use perforated or micro-perforated films that allow for air exchange while keeping light and moisture out. These films help maintain the freshness of produce by slowing down the respiration process and reducing water loss.</p>

- Q: This question asks for guidance on preparing a nutritious meal using aluminum foil as a cooking method.

- <p>To make a healthy meal using aluminum foil, consider 'foil packet cooking'. Choose lean protein like chicken or fish, and pair it with a variety of colorful vegetables such as bell peppers, zucchini, and cherry tomatoes. Season with herbs, garlic, and a drizzle of olive oil. Fold the foil to create a sealed packet and bake in the oven at 400掳F (200掳C) for about 20-25 minutes or until the protein is cooked through and the vegetables are tender. This method retains nutrients and flavors while minimizing added fats.</p>

- Q: This question asks for a method to clean oil stains that have occurred on aluminum foil used to cover food in a microwave.

- <p>To clean oil stains from aluminum foil used in the microwave, first let the foil cool down to avoid burns. Then, gently wipe the surface with a paper towel to remove excess oil. For stubborn stains, mix a solution of warm water and dish soap. Dip a soft cloth or sponge into the solution and gently scrub the foil. Rinse with warm water and dry thoroughly. For severe stains, you can also use a mixture of baking soda and water to create a paste, apply it to the stain, let it sit for a few minutes, then scrub and rinse. Always check the manufacturer's guidelines for cleaning aluminum foil as some may have specific recommendations or restrictions.</p>

- Q: What are the primary applications or purposes of aluminum foil facing in various industries or everyday life?

- <p>Aluminum foil facing is primarily used for its heat reflective properties, making it ideal for insulation in construction and roofing. It also serves as a moisture barrier and vapor barrier in walls and ceilings, helping to prevent mold and mildew. In the HVAC industry, it's used for duct insulation, enhancing energy efficiency. Additionally, it's utilized in packaging for food and pharmaceuticals to protect contents from light, air, and moisture, thus preserving freshness and quality.</p>

- Q: This question asks if there are any potential issues or risks associated with storing food in plastic containers for extended periods.

- <p>Yes, there are concerns about using plastic containers for long-term food storage. Certain plastics can leach chemicals, such as BPA (Bisphenol A) and phthalates, which may be harmful when ingested over time. These chemicals can migrate into the food, especially with exposure to heat or over extended periods. Additionally, plastic containers can break down over time, potentially releasing harmful substances into the food. It's recommended to use food-grade, BPA-free plastics or alternatives like glass containers for long-term storage to minimize health risks.</p>

- Q: How should aluminum foil be properly stored when not in use to maintain its quality and usability?

- <p>The best ways to store aluminum foil when not in use include keeping it in a cool, dry place away from direct sunlight to prevent degradation. It's advisable to store it in its original box or a resealable plastic container to protect it from moisture and air exposure. Some people also use a paper towel roll as a dispenser by placing the aluminum foil around it, ensuring the shiny side is out for easy access. Keeping it in a drawer is also common, but it's important to prevent it from crumpling or tearing.</p>

- Q: This question asks for a comparison between domestic and foreign aluminum foil, specifically focusing on their differences.

- <p>The differences between domestic and foreign aluminum foil facing primarily lie in material quality, manufacturing processes, and market positioning. Domestic aluminum foil often uses locally sourced materials and may have variations in thickness and quality, while foreign foil might employ higher-grade materials for enhanced durability and consistency. Manufacturing processes abroad may incorporate advanced technology, leading to better surface smoothness and uniformity. Additionally, foreign aluminum foil is often marketed as premium, targeting niche segments with specific requirements for quality and performance. Domestic foil, on the other hand, is generally more affordable and caters to a broader market, including everyday household use.</p>

Send your message to us

Construction Rubber Foam Insulation Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords