Aluminum Foil Facing Uninsulated Insulated Flexible Ducts in Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Features and Characters of Aluminium Flexible Duct:

-Applied in Heating, Ventilation and Air Conditioning

-Non-insulated and insulated Flexible Duct offered

-Up to 150℃ and 250℃ high temperature

-Fire Retardant

-Corrosion Resistant

-High flexibility

-Convenient installation

-Non- toxic

Description of Aluminium Flexible Duct

Flexible Duct is widely used in Heating, Ventilation and Air Conditioning (HVAC) systems for air ventilation applications. Flexible Duct provides greater thermal efficiency to save energy. The product is also covered in a heavy duty, silver jacket for durability. The vapor barrier prevents condensation forming on the outside of ducts carrying air. Because it is flexible, it is easy to run around and through obstacles in the building.

Specification of Aluminium Flexible Duct:

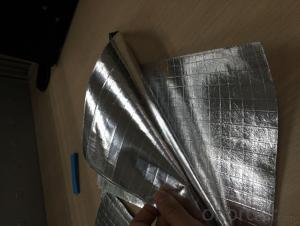

Non-insulated Flexible Duct: Structure: Two-layer aluminum foils +1 layer of PET film.

Pictures of Aluminium Flexible Duct:

FAQ of Aluminium Flexible Duct:

1. What temperature maximum? Our products: 150℃ and 250℃

2. What MOQ? Our MOQ: 500 pcs

3. What payment terms? We accept T/T and L/C

4. Lead time: 10 days

5. Packing: Nest packing for non-insulated flexible duct, then into plastic bag for non-insulated flexible duct or packed in individual carton box.

- Q: This question asks for instructions on how to store aluminum foil after it has been used.

- <p>To store aluminum foil facing after use, first, wash and dry it thoroughly to remove any residue. Roll it up tightly, starting from the end that has been used, to keep the cleanest part of the foil on the outside. You can also use a rubber band or a piece of tape to secure the roll. Store it in a cool, dry place, away from direct sunlight to prevent it from losing its shine and becoming brittle. If you have a dispenser, you can also reinsert the foil back into the dispenser for neat and organized storage.</p>

- Q: This question asks for a method to determine the thickness of an aluminum foil sheet.

- <p>To measure the thickness of an aluminum foil sheet, you can use a digital caliper or a micrometer. Place the foil between the jaws of the caliper and take the measurement. If you don't have these tools, you can use the 'multiple fold' method: fold the foil in half repeatedly and measure the total thickness after several folds, then divide by the number of layers to estimate the single layer thickness. For a more precise measurement, especially for thinner foils, consider using a thickness gauge designed for measuring thin materials.</p>

- Q: Is it possible to use aluminum foil with a reflective side to cover leftover food?

- <p>Yes, aluminum foil facing can be used to wrap leftovers. The reflective side of aluminum foil is often used for its heat-reflective properties in cooking, but it is also suitable for wrapping and storing leftovers. It provides a barrier to air, helping to keep food fresh and preventing freezer burn if used in the freezer. However, it's important to ensure that the foil is tightly sealed around the food to maintain its freshness and prevent contamination.</p>

- Q: This question asks for instructions on how to clean aluminum foil facing after it has been used in cooking or baking.

- <p>To clean aluminum foil facing after use, first let it cool down to avoid burns. Then, gently scrape off any food residue with a spatula or the edge of a knife. For stubborn stains, mix a solution of warm water and dish soap, and wipe the surface with a soft cloth or sponge. Rinse with clean water and dry thoroughly. For baked-on food, you can use a plastic scraper or an old toothbrush to gently remove it. Avoid using abrasive materials that could scratch the surface. Regular cleaning will help maintain the integrity and appearance of your aluminum foil facing.</p>

- Q: Is it possible to use aluminum foil with a reflective surface for storing fruits and vegetables?

- <p>Aluminum foil facing can be used for storing fruits and vegetables, but it's not the best choice. Aluminum foil is not breathable and can cause condensation, leading to spoilage. It's better to use perforated or micro-perforated films that allow for air exchange while keeping light and moisture out. These films help maintain the freshness of produce by slowing down the respiration process and reducing water loss.</p>

- Q: Is it possible for metal shavings to contaminate food when using aluminum foil with a shiny side?

- <p>There is minimal risk of metal shavings getting into food when using aluminum foil facing. Aluminum foil is designed to be safe for food contact and is generally resistant to shedding particles. However, if the foil is damaged or handled roughly, small particles could potentially come off. To mitigate this risk, ensure the foil is in good condition, avoid tearing it, and handle it carefully to prevent any metal contamination.</p>

- Q: Is it safe to use aluminum foil facing to wrap food for cooking methods like roasting or grilling?

- <p>Yes, you can use aluminum foil facing to wrap food before roasting or grilling. Aluminum foil is a common and safe material used in cooking, especially for wrapping foods to retain moisture and flavor. It's important to ensure the foil is food-grade and not damaged, as this can affect the food's safety and taste. When using foil, make sure it's sealed properly to prevent juices from leaking and to keep the food moist. Avoid direct contact with the heat source as much as possible to prevent the foil from burning and potentially releasing any harmful substances into the food.</p>

- Q: What are the various uses of aluminum foil facing across different sectors?

- <p>Aluminum foil facing is widely used across various industries due to its properties such as heat resistance, moisture barrier, and durability. In construction, it's used for insulation and moisture protection in walls and roofs. In the food industry, it's essential for packaging to preserve freshness and extend shelf life. In the automotive sector, it's used for heat shielding and soundproofing. Additionally, it's utilized in aerospace for lightweighting and heat protection, and in pharmaceuticals for blister packaging. Its versatility makes it indispensable in many manufacturing processes and product applications.</p>

- Q: What are the various materials used as facings for aluminum foil, and how do they differ from one another?

- <p>Aluminum foil facing materials are used in construction and insulation to provide a barrier against air and moisture. The different types include: 1) Kraft paper facing, which is a strong, absorbent paper used for general purposes; 2) Glassine facing, a thin, glossy paper with good water resistance; 3) PE-coated facing, where a layer of polyethylene is applied for enhanced water resistance; 4) Aluminum foil facing, which is a thin layer of aluminum for superior barrier properties; 5) Silicone-treated glass fabric, offering high-temperature resistance and used in high-performance applications. Each type has unique properties affecting their use in various applications.</p>

- Q: This question asks for a comparison between domestic and foreign aluminum foil, specifically focusing on their differences.

- <p>The differences between domestic and foreign aluminum foil facing primarily lie in material quality, manufacturing processes, and market positioning. Domestic aluminum foil often uses locally sourced materials and may have variations in thickness and quality, while foreign foil might employ higher-grade materials for enhanced durability and consistency. Manufacturing processes abroad may incorporate advanced technology, leading to better surface smoothness and uniformity. Additionally, foreign aluminum foil is often marketed as premium, targeting niche segments with specific requirements for quality and performance. Domestic foil, on the other hand, is generally more affordable and caters to a broader market, including everyday household use.</p>

Send your message to us

Aluminum Foil Facing Uninsulated Insulated Flexible Ducts in Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords