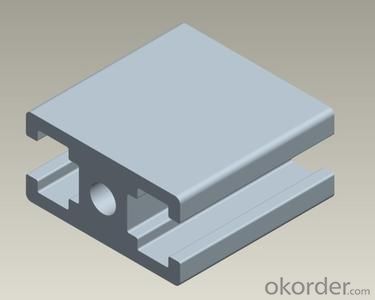

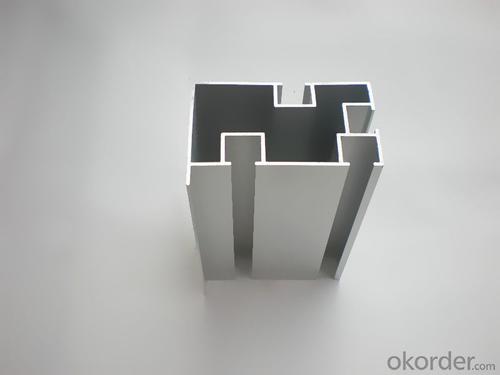

Aluminum Fascia Profiles 6063 T5 Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

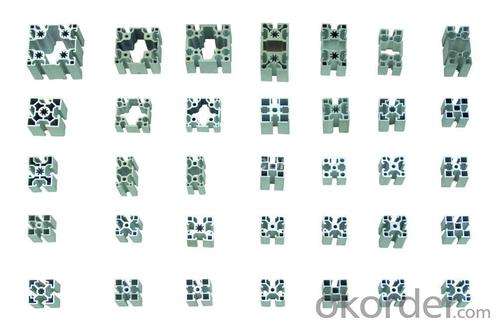

Aluminum Profile

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: What are the vibration damping properties of aluminum profiles?

- Aluminum profiles have excellent vibration damping properties. Due to their high stiffness-to-mass ratio, aluminum profiles effectively absorb and dissipate vibrations, reducing their magnitude and preventing their transmission to surrounding structures. This property makes aluminum profiles ideal for applications where vibration control is critical, such as in the aerospace, automotive, and construction industries. The inherent damping characteristics of aluminum profiles help in minimizing noise, minimizing wear and tear, and ensuring structural integrity. Additionally, aluminum's ability to dampen vibrations also enhances the overall comfort and safety of various products and structures.

- Q: Explain the various methods used to install aluminum profiles in construction projects.

- <p>There are several methods to install aluminum profiles in construction: 1. Bolting: Aluminum profiles can be secured with bolts and nuts, providing a strong and adjustable connection. 2. Welding: For permanent and rigid connections, aluminum profiles can be welded together. 3. Adhesive bonding: Using specialized adhesives, aluminum profiles can be bonded together for a secure fit. 4. Clipping: Some profiles come with clip-on connectors that allow for quick and easy assembly. 5. Screwing: Self-tapping screws can be used to join aluminum profiles, providing a strong hold without the need for pre-drilled holes. 6. Mortise and tenon: A traditional woodworking joint that can be adapted for aluminum profiles, creating a tight and secure fit. Each method has its advantages and is chosen based on the specific requirements of the construction project.</p>

- Q: Can aluminum profiles be used in construction?

- Indeed, construction can benefit from the utilization of aluminum profiles. This material boasts properties such as being lightweight, durable, and resistant to corrosion, thereby rendering it suitable for a multitude of construction purposes. Common applications encompass the construction of windows, doors, curtain walls, and roofing systems. Notably, the versatility of aluminum profiles permits the realization of intricate designs and structures. Furthermore, it is crucial to acknowledge that aluminum is an eco-conscious option for construction endeavors due to its high recyclability.

- Q: In aluminum processing, countersunk holes and via holes what difference?

- Through the hole, as the name suggests, that is, through, through the appropriate size of objects or liquid holes, the role is: A, used for connection, can be threaded through holes. B, a cylinder for a piston engine. C, in the distribution of pump for transporting liquid, gas and dust loading objects etc.. D, in life, we are wearing clothes, trousers and hole application examples.

- Q: What are the different bending radii available for aluminum profiles?

- The different bending radii available for aluminum profiles can vary depending on the specific profile and its dimensions. However, common bending radii for aluminum profiles typically range from 1.5 to 3 times the profile's wall thickness.

- Q: Are aluminum profiles suitable for use in the telecommunications industry?

- Indeed, the telecommunications industry finds aluminum profiles to be a fitting option. Aluminum, a lightweight and durable material, offers numerous advantages in this field. Firstly, aluminum profiles possess corrosion-resistant qualities, rendering them ideal for outdoor installations like telecommunication towers and antennas which endure harsh weather conditions. This resistance to corrosion ensures the equipment's longevity and reliability. Secondly, aluminum profiles exhibit exceptional thermal conductivity properties, enabling efficient heat dissipation. This attribute holds significant importance in the telecommunications sector, where electronic components generate heat that can impair their performance. By adopting aluminum profiles, cooling systems can be optimized, guaranteeing the equipment's proper functioning. Moreover, aluminum profiles are remarkably versatile, allowing easy customization and fabrication to meet specific requirements. This empowers telecommunications companies to design and construct tailored structures, enclosures, and mounting solutions. Aluminum profiles can be conveniently assembled, disassembled, or modified as needed, offering flexibility in installation and maintenance. Additionally, aluminum profiles provide electromagnetic shielding properties, playing a crucial role in minimizing interference between different communication systems. This shielding helps maintain the quality and reliability of transmitted signals. Furthermore, aluminum stands as a sustainable material, being 100% recyclable and possessing a low carbon footprint compared to other metals. This renders it an environmentally friendly choice for the telecommunications industry, aligning with the increasing emphasis on sustainability and reducing environmental impact. In conclusion, due to their corrosion resistance, thermal conductivity, versatility, electromagnetic shielding properties, and sustainability, aluminum profiles prove to be highly suitable for implementation in the telecommunications industry. These qualities establish aluminum profiles as a dependable and efficient choice for various applications in telecommunications infrastructure.

- Q: How to calculate the spraying powder of aluminium profile?

- Ask not detailed, do not know what you want to ask is how?

- Q: How do aluminum profiles compare to other materials used for construction and manufacturing?

- Aluminum profiles offer numerous advantages compared to other materials used in construction and manufacturing. Firstly, aluminum is lightweight yet strong, making it easier to handle and transport while maintaining structural integrity. Additionally, aluminum profiles are highly corrosion-resistant, making them suitable for outdoor and marine applications. Furthermore, aluminum is non-combustible, providing a significant safety advantage. Moreover, aluminum profiles are versatile and can be easily customized to meet specific design requirements. Lastly, aluminum is highly recyclable, making it a sustainable choice for environmentally conscious projects.

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum profiles in the construction of buildings.

- <p>Aluminum profiles in building construction offer several advantages such as high strength-to-weight ratio, corrosion resistance, and ease of fabrication. They are lightweight, which reduces the load on structures, and they are recyclable, contributing to sustainability. Additionally, aluminum profiles can be easily shaped and joined, making them versatile for various architectural designs. However, they also have disadvantages. Aluminum is a good conductor of heat, which can lead to thermal bridging and energy inefficiency if not properly insulated. It can also be more expensive than some traditional materials like steel or wood. Moreover, aluminum's light color can cause glare issues, and it may require additional protective coatings to prevent weathering and maintain its appearance over time.</p>

- Q: This question asks about the various types of aluminum profiles that are utilized in the construction of exterior wall systems.

- <p>Aluminum profiles for exterior wall systems include several types: 1. <strong>Vertical and Horizontal Mullions</strong>: These are the main structural components that form the framework of the system. 2. <strong>Transoms and Muntins</strong>: These profiles divide the large glass panes into smaller sections, providing structural support and aesthetic appeal. 3. <strong>Cover Caps</strong>: Used to cover the joints and intersections of the profiles, enhancing the visual appearance and weatherproofing. 4. <strong>Sill Channels</strong>: Installed at the base of windows to direct water away from the building. 5. <strong>Head Channels</strong>: Positioned at the top of the window or door openings. 6. <strong>Jamb Liners</strong>: These are used to reinforce the sides of the openings. 7. <strong>Gaskets and Seals</strong>: Essential for weatherproofing and insulation. Each type serves a specific function in ensuring the stability, durability, and aesthetic of the exterior wall system.</p>

Send your message to us

Aluminum Fascia Profiles 6063 T5 Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords