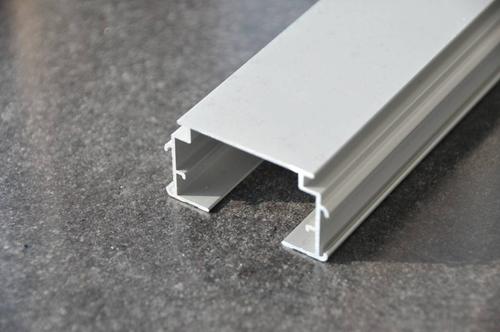

Aluminum Extrusions Profiles for Cable Trough

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Profile for Cable Trough

Usage:Cable trough

Surface:Anodizing,Powder coating, Electrophoresis

Alloy:6063

Size:according to customer’s requirement

Advantage:Durability, good corrosion resistance and lightweight

Package:Normal paper package and soft plastic interleaving each profile to protect the surface. In case of any special package, additional packing cost will be charged.

product details | |

Material | Alloy:6063,6061,6060,6005,7005 |

State | Mainly T5/T6 |

Thickness | above 1.0mm;recommend 1.2mm and above,customized available |

Normal Anodizing thickness | 8-12 micro |

Normal power coating thinkness | 600-100 micro |

Tensile strength | ≥ 16 mpa |

Yield strength | ≥ 110 mpa |

Extensibility | ≥ 8% |

Hardness(HW) | ≥ 8 |

Surface Treatment | 1) Mill finish |

Length | 1m-7m,Customized is available |

Packing | Kraft paper, EPE Fram, Shrink film, Composite paper,etc |

Standard | QC:ISO, SGS |

Time of samlple | 10-18days,including making mould |

Deep precessing ability | Drill holes,stretch bneding,milling,welding,fabrication etc |

Order process | 1.drawing/colors/price confirmed |

Trade terms | FOB Qingdao, CIF or CFR to the appointed port. |

Payment terms | T/T ,L/C,etc |

MOQ | 1*20 FCL |

- Q: What are the differences between the aluminum profile material and the anodized aluminum profile? Where are they used? If it is necessary to spray the fluorocarbon paint on aluminum, do it on the basis of anodic oxidation or on the aluminum profile material?

- The surface of the material is not oxidized. The oxidized aluminum profile has a smooth and beautiful surface. According to your requirements, choose material

- Q: This question asks for guidance on selecting a trustworthy supplier of aluminum profiles used in construction.

- <p>To choose a reliable supplier of aluminum profiles for building construction, consider the following: Check their industry reputation and customer reviews. Ensure they have the necessary certifications and quality standards compliance. Evaluate their product range and quality, comparing different suppliers' offerings. Assess their delivery times and reliability. Consider their after-sales service and warranty provisions. Finally, get quotes from multiple suppliers and compare prices while ensuring quality is not compromised.</p>

- Q: Are aluminum profiles suitable for use in automotive body structures?

- Yes, aluminum profiles are suitable for use in automotive body structures. Aluminum is a lightweight and durable material that offers several advantages in the automotive industry. Its high strength-to-weight ratio makes it an ideal choice for constructing body frames, panels, and other structural components. Using aluminum profiles in automotive body structures offers benefits such as improved fuel efficiency, as the lighter weight of the material reduces the overall weight of the vehicle. This, in turn, allows for better acceleration and handling. Additionally, aluminum possesses excellent corrosion resistance, which is crucial for withstanding harsh environmental conditions and extending the lifespan of the vehicle. Furthermore, aluminum profiles can be easily shaped and formed into complex designs, allowing for greater design flexibility in automotive body structures. This versatility enables manufacturers to create more aerodynamic and visually appealing vehicles. While aluminum profiles offer numerous advantages, there are also some considerations to be aware of. Aluminum can be more expensive than traditional steel, which may impact the overall cost of the vehicle. Additionally, the repair and maintenance of aluminum structures may require specialized equipment and expertise. However, these factors are outweighed by the benefits aluminum profiles bring to the automotive industry. In conclusion, aluminum profiles are indeed suitable for use in automotive body structures. Their lightweight, durable, and corrosion-resistant properties, along with their design flexibility, make them an excellent choice for constructing modern vehicles.

- Q: What are the potential effects on the environment when aluminum profiles are used in the construction of buildings?

- <p>The use of aluminum profiles in building construction has both positive and negative environmental impacts. On the positive side, aluminum is lightweight, which reduces the energy required for transportation and can contribute to a building's energy efficiency. It is also recyclable, with a high recycling rate, which helps to conserve resources and reduce waste. However, the production of aluminum is energy-intensive and generates greenhouse gas emissions. Additionally, the extraction of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. The environmental impact of using aluminum profiles in construction must therefore be balanced against these factors.</p>

- Q: Can aluminum profiles be used in agricultural machinery manufacturing?

- Yes, aluminum profiles can be used in agricultural machinery manufacturing. Aluminum is a lightweight and versatile material that offers various benefits for agricultural machinery. It is corrosion-resistant, which is essential for equipment exposed to harsh weather conditions and chemicals used in farming. Additionally, aluminum profiles provide excellent strength-to-weight ratio, allowing for the construction of sturdy and durable machinery without adding unnecessary weight. Aluminum's high thermal conductivity also enables efficient heat dissipation, preventing overheating of machinery components. Moreover, aluminum profiles can be easily formed, machined, and welded, providing flexibility in design and manufacturing processes. Overall, the use of aluminum profiles in agricultural machinery manufacturing can result in improved performance, fuel efficiency, and reduced maintenance costs.

- Q: What are the methods to protect aluminum profiles from corrosion during the installation and usage phases?

- <p>To prevent corrosion of aluminum profiles during installation and use, follow these steps: 1. Choose high-quality aluminum profiles with proper alloy composition that resists corrosion. 2. Ensure the surface is clean and free from contaminants before installation. 3. Apply a protective coating such as a clear anodized finish, powder coating, or paint to the aluminum surface. 4. Avoid contact with corrosive substances like saltwater or chemicals. 5. Regularly inspect and clean the profiles to remove dirt and debris that can lead to corrosion. 6. Use stainless steel fasteners and avoid dissimilar metal contact, as it can accelerate corrosion. 7. Maintain a dry environment to prevent moisture-induced corrosion. By following these practices, you can significantly reduce the risk of corrosion and prolong the lifespan of aluminum profiles.</p>

- Q: What are the potential health risks associated with handling aluminum profiles?

- <p>Working with aluminum profiles generally does not pose significant health concerns under normal conditions. However, there are a few considerations. Inhalation of aluminum dust can cause respiratory issues, and prolonged exposure may lead to a condition known as 'aluminum dust disease.' Additionally, aluminum can cause skin irritation in some individuals, especially with prolonged contact. It's important to use proper personal protective equipment (PPE), such as masks and gloves, to minimize these risks. Ingestion of aluminum is also a concern, as it can lead to health problems if it enters the body through contaminated food or water, although this is not directly related to handling aluminum profiles.</p>

- Q: This question is asking about the various types of aluminum profiles that are used for exterior cladding purposes.

- <p>Aluminum profiles for exterior cladding are diverse and serve various architectural and functional needs. Some common types include: 1. Flat Profiles: Used for simple, sleek designs. 2. Box Profiles: Ideal for creating a modern, industrial look. 3. Angle Profiles: Useful for corners and edges. 4. Channel Profiles: Often used for window and door frames. 5. T-Profiles: Commonly used for hidden fastening systems. 6. U-Channels: Suitable for cover applications. 7. Special Profiles: Custom designs for specific architectural requirements. Each type offers unique benefits in terms of aesthetics, strength, and weather resistance, making them suitable for different building facades and exterior applications.</p>

- Q: What are the noise insulation properties of aluminum profiles?

- Aluminum profiles have good noise insulation properties due to their density and ability to dampen sound vibrations. They can effectively reduce external noise and provide a quieter indoor environment.

- Q: What are the weight capacities of aluminum profiles for shelving systems?

- The weight capacities of aluminum profiles for shelving systems can vary depending on various factors such as the dimensions of the profiles, the design of the shelving system, and the quality of the aluminum used. Generally, aluminum profiles used for shelving systems can support a significant amount of weight. However, it is important to note that the weight capacity of a shelving system also depends on other components such as brackets, connectors, and the type of shelving material used (e.g., wood, glass, or metal shelves). It is recommended to consult the manufacturer or supplier of the specific aluminum profile and shelving system to obtain accurate weight capacity information. They can provide guidelines based on their product specifications, engineering calculations, and testing. Additionally, factors such as proper installation, distribution of weight, and regular maintenance also play a crucial role in ensuring the overall strength and stability of a shelving system.

Send your message to us

Aluminum Extrusions Profiles for Cable Trough

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords