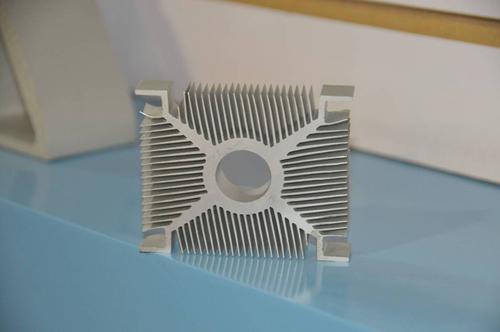

Aluminum Corner Extrusion Profiles for Industrial Field Equipment Chilling

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Aluminum extrusion radiator profile for industry field equipment chilling

1. Usage: Industrial radiator

2. Surface:Anodizing, Powder coating, Electrophoresis

3. Alloy:6063

4. Size:according to customer’s requirement

5. Advantage:Durability, good corrosion resistance and lightweight

6. Package:Normal paper package and soft plastic interleaving each profile to protect the surface. In case of any special package, additional packing cost will be charged.

- Q: Can aluminum profiles be used in curtain wall systems?

- Yes, aluminum profiles can be commonly used in curtain wall systems. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for constructing curtain walls. Its versatility allows for various design options and structural support, making it a popular choice in the construction industry.

- Q: Who would like to know, aluminum radiator mainly used in which instruments or equipment, trouble to say more detailed points, thank you

- Large, such as ZTE, HUAWEI communications control center, as well as the main table server, large cabinet

- Q: Can aluminum profiles be used in signage or display applications?

- Yes, aluminum profiles can be used in signage or display applications. Aluminum profiles are lightweight, durable, and versatile, making them suitable for various applications such as sign frames, display stands, and exhibition booths. Additionally, aluminum profiles can be easily customized and offer a sleek and modern appearance, making them a popular choice in the signage and display industry.

- Q: What are the different surface patterns or textures available for aluminum profiles?

- There are several surface patterns or textures available for aluminum profiles, each offering unique aesthetic and functional qualities. Some of the most common options include: 1. Smooth: This is the most basic and commonly used surface finish, providing a sleek and polished appearance. It is achieved through a process of grinding and polishing the aluminum surface. 2. Brushed: Brushed aluminum profiles have a linear texture that is created by brushing the surface with an abrasive material. This gives the metal a distinctive grain and a slightly matte appearance. 3. Anodized: Anodizing is an electrochemical process that enhances the natural oxide layer on the aluminum surface. This results in a durable and corrosion-resistant finish with a variety of color options. 4. Powder-coated: Powder coating involves applying a dry powder to the aluminum surface and then curing it with heat to create a hard and decorative finish. It can be customized with various colors and textures. 5. Textured: Textured aluminum profiles feature a patterned surface that adds visual interest and can provide improved grip or friction. These patterns can range from subtle to more pronounced, depending on the desired effect. 6. Wood grain: Wood grain finishes are achieved through a process called sublimation, where a high-resolution image of wood grain is transferred onto the aluminum surface. This allows for the appearance of wood without the maintenance requirements. 7. Embossed: Embossed aluminum profiles have raised or recessed patterns that are created through a mechanical or hydraulic process. These patterns can be decorative or functional, providing enhanced grip or structural strength. 8. Diamond plate: Diamond plate is a type of textured finish that features a raised diamond pattern on the surface. It is commonly used in industrial or high-traffic applications for its slip-resistant properties. Overall, the choice of surface pattern or texture for aluminum profiles depends on the specific application, desired aesthetic, and functional requirements. Manufacturers often offer a range of options to cater to varying needs and preferences.

- Q: Can aluminum profiles be used for modular systems or frameworks?

- Indeed, modular systems or frameworks can utilize aluminum profiles. These profiles possess the qualities of being lightweight, sturdy, and exhibiting exceptional structural integrity, rendering them an optimal selection for the construction of modular systems or frameworks. The ease with which these profiles can be assembled and disassembled grants designers the freedom to modify and adjust structures as needed. Moreover, aluminum profiles exhibit commendable resistance against corrosion, rendering them appropriate for both indoor and outdoor applications. Furthermore, their sleek and contemporary aesthetic appeal contributes to their popularity in architectural and industrial design. In conclusion, aluminum profiles represent a versatile and trustworthy choice for the creation of modular systems or frameworks.

- Q: Are there any differences between aluminum alloy and aluminum alloy?

- Aluminum alloy refers to the material, aluminum alloy refers to the productIt's like the difference between gold and gold

- Q: Can aluminum profiles be used in railway and transportation infrastructure?

- Yes, aluminum profiles can be used in railway and transportation infrastructure. Aluminum is a lightweight and durable material that offers excellent strength-to-weight ratio, corrosion resistance, and easy fabrication. It can be used in the construction of train bodies, windows, doors, and various structural components. Additionally, aluminum profiles are recyclable, making them environmentally friendly and cost-effective for transportation projects.

- Q: What is the terminology to explain the aluminum twist and bending and a sharp respectively.

- Curvature:1. longitudinal bending: the profile is placed on the platform, and when the weight is stable, the maximum gap between the bottom of the profile and the platform is measured along the length of the profile, that is, the longitudinal curvatureThe 2. longitudinal wave degree (or bend): the section on the platform, to achieve stability by self, the ruler will be 300mm long (or flat on the surface of the profile cutter) waves or hard along the length direction of a profile, profile measurement and rule (or ruler knife) between the maximum gap value that is, longitudinal wave degree (or bend).

- Q: What are the features of the poor aluminum profiles?

- Poor quality aluminum profile:1, chemical composition unqualified, seriously endanger the safety of construction projects.2 、 profile corrosion resistance function is low.3, the film thickness is thin. The national standard rules of construction of aluminum oxide film thickness not less than 10um (m). The thickness is not enough, aluminum looks easy to rust and corrosion. Some no name and address, production license, certificate of inspection in the aluminum oxide film, the thickness of only 2 to 4um, some even without film.

- Q: This question asks about the various methods employed in the production of aluminum profiles, which are long, extruded shapes made from aluminum.

- <p>Aluminum profiles are manufactured using several processes, primarily extrusion, which involves forcing aluminum through a die to create specific shapes. Other processes include casting, where aluminum is poured into molds, and rolling, used to create flat sheets or plates. Machining processes like cutting, drilling, and milling are also used for further shaping and finishing. Additionally, aluminum profiles can be fabricated through bending, which shapes the material into curves or angles, and welding, which joins pieces together. Surface treatments like anodizing, painting, or powder coating are also applied to enhance appearance and durability.</p>

Send your message to us

Aluminum Corner Extrusion Profiles for Industrial Field Equipment Chilling

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords