6061-T6 Aluminum Coil for Wine/Medicine PP Cap

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

8011 HO Aluminum Coil for Wine/ Medicine PP Cap

l Product Introduction

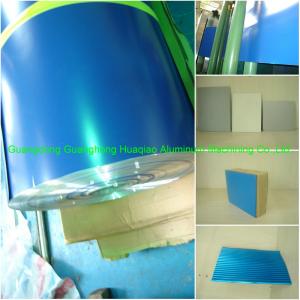

We offer 8011, 3105, 3003, 3005 HO, H14, H16, H18 aluminium coil for lids (caps) crystal segment is uniform, which makes its deep stamping property excellence. These products are widely used in Wine bottles, Pilfer-proof caps, ROPP cap, Pharmceutical cap, etc.

l Product Specification

1. Alloy: 8011, 3105, 3005, 3003

2. Temper: HO, H14, H24, H16, H26,H18

3. Pattern: rolled, degreased, pre-lubricated, pre-treated, lacquered

4. Thickness: 0.19-0.3 (0.23/0.22/0.27) mm

5. Width: 500-1200 (829/880/1085) mm

6. Length: as requirement, or in coil

7. Coil ID: 75, 150, 300, 500, etc

8. Payment Terms: 30% by TT in advance as deposit and the rest payment upon delivery or irrevocable, confirmed L/C at sight;

9. Lead Time: about 15~30 days after deposit

l Packaging & Delivery

Packaging detail: Seaworthy Export Standard Wooden Pallet and with damp proof film as first layer, Kraft paper as second layer, Cardboard card as third layer Criss-cross steel strip to fix outside

Delivery detail: About 25 days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

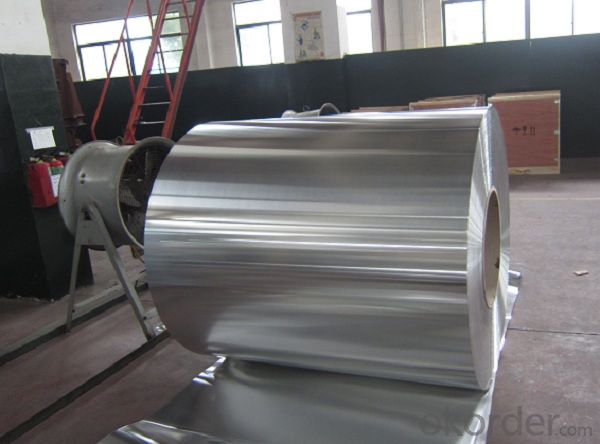

l Products Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: What causes tower after cutting aluminum coil

- Insulation aluminum coil will appear when the cooling bending phenomenon, reason is generally under the conditions of air cooling, the heat transfer coefficient of the aluminum coil insulation parts in contact with the air were flat, but because the wall thickness or different shapes, different parts of the heat dissipation rate is not balanced, resulting in thick wall or hollow tube heat faster than the thin Department of slow, resulting in insulating aluminum roll cooling occurs to the hollow part.

- Q: To put aluminum heads on my car do i have to add other things or basically can i just get them and put them on

- Aluminum heads will warp the first time the engine accidentally overheats. Why would you go with aluminum?

- Q: Dongying power plant with 0.6mm thick insulation aluminum coil, manufacturers can be divided into small volumes?

- Tolerable。 The price depends mainly on what you need to split into.

- Q: How heavy and long is the aluminum rolling on average?

- The blank aluminum coil of aluminum manufacturer is about 5-6 tons, while the aluminum coil of dealer or supplier depends on the feeding frame, about 1.5-2 tons or 3 tons.

- Q: How are aluminum coils used in the production of musical instruments?

- Aluminum coils are commonly used in the production of musical instruments, particularly in wind instruments like saxophones and trumpets. These coils are shaped into a specific design and attached to the instrument to create the desired sound. The aluminum material allows for a lightweight and durable construction, enhancing the instrument's playability and resonance.

- Q: What are the precautions to be taken while handling aluminum coils?

- To ensure safety and prevent potential accidents or damage, there are several precautions that should be taken when dealing with aluminum coils. First and foremost, it is essential to wear the appropriate personal protective equipment (PPE), including gloves, safety goggles, and protective clothing. This gear will help safeguard against cuts, abrasions, and exposure to chemicals. It is also crucial to handle aluminum coils with care to avoid any harm or deformation. Dropping or mishandling the coils can compromise their structural integrity and potentially lead to injuries. Furthermore, one must be mindful of the weight of the coils and employ proper lifting techniques. If the coils are too heavy to lift safely, seeking assistance or utilizing mechanical lifting equipment is imperative to prevent strain or injury. Moreover, aluminum coils should be stored and transported securely and stably. They should be placed on a flat and even surface and adequately secured to prevent any movement or rolling. During transportation, it is essential to ensure that the coils are well protected against potential damage or external forces. In addition, maintaining a clean work area, free from clutter or obstacles that may cause accidents, is of utmost importance. Any spills or leaks should be promptly cleaned up to prevent slips or falls. Lastly, it is crucial to adhere to all safety guidelines and procedures provided by the manufacturer or employer. This includes understanding the specific properties and hazards associated with aluminum coils and following any recommended handling or storage instructions. By following these precautions, individuals can minimize the risk of accidents, injuries, and damage while handling aluminum coils.

- Q: Are aluminum coils suitable for marine applications?

- Yes, aluminum coils are suitable for marine applications due to their excellent corrosion resistance properties in saltwater environments.

- Q: Is it possible to utilize a band saw for cutting an aluminum coil?

- <p>Yes, you can use a band saw to cut an aluminum coil. Band saws are versatile and can cut a variety of materials, including aluminum. However, it's crucial to use the right blade designed for metal cutting. Ensure the blade is sharp and has the appropriate teeth pitch for aluminum to avoid damaging the material or the blade. Adjust the speed to a lower setting to prevent overheating and ensure a clean cut. Always follow safety precautions and wear protective gear when operating power tools.</p>

- Q: What are the common surface finishes for aluminum coils in the aerospace industry?

- The common surface finishes for aluminum coils in the aerospace industry include mill finish, anodized finish, and painted finish.

- Q: I have a 1994 Impala SS with a 5.7L lt1 engine with cast iron heads. Which is better in horsepower gain? Aluminum heads or cast iron heads? People say cast iron heads downsize the hp from 300 to 260 hp. Also which of the two heads are more durable and less restrictive?

- If they are exactly the same with the exception of 1 being aluminum and the other being iron the iron one will make slightly more power. The 2 big differences are you can run higher compression with aluminum and there is a big weight difference.

Send your message to us

6061-T6 Aluminum Coil for Wine/Medicine PP Cap

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords