1060 Anti-Corrosion Color Coated Aluminum Coil for Roofing and Cladding System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1060/1050 Aluminium Coil for Transformer/ Electronic Components

l Product Description

Alloy: | A1100, A1050, A1060,A3003, A3004, A3005, A3105 , A5052, , A5754, A8011 etc. | |

2 | Temper: | H14, H16, H18, H24 etc. |

3 | Thickness: | 0.2mm - 2.0mm |

4 | Width: | 15mm - 1600mm |

5 | Color: | chromic,white,metallic and so on(Customized, choose from RAL color chart or refer to customers' counter sample.) |

6 | Coating: | Polyester(mainly),Fluorocarbon(mainly),polyurethane and epoxy coating ect. |

7 | Coating thickness: | PVDF≥25 micron; PE≥18 micron. |

8 | Surface Quality: | be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use. |

9 | Mechanical Property: | Chemical Composite and Mechanical Property are meted with GB/T, ASTM, ENAW Standard. |

10 | Interior diameter: | 105mm or 405mm or 505mm |

11 | Coating hardness: | (pencil hardness) more than 2H |

12 | Impact resistance: | no cracking and peeling(≥50kg/cm) |

13 | Flexibility(T-bend) : | ≤ 2T |

14 | MEK resistance: | more than 100 |

15 | Packaging Detail: | standard export packing in carton and wooden pallet |

16 | Payment Detail: | 30% deposit by T/T in advance,70% balance should be paid upon BL copy |

18 | Application: | roofs, facade cladding, ceilings, aluminum curtains, composite panels, pipe wrap, advertisement plates, instrument panels, and other uses. |

l Packaging & Delivery

Packaging detail: pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: within 30 days after we get your 30% deposit or L/C

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

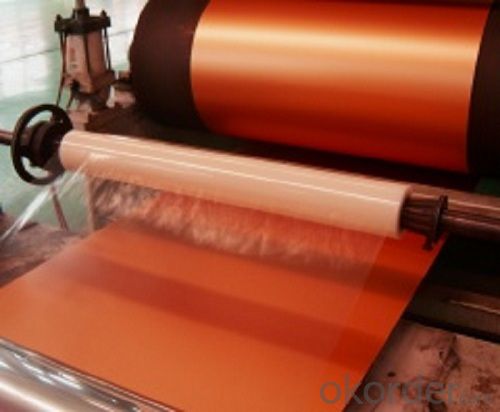

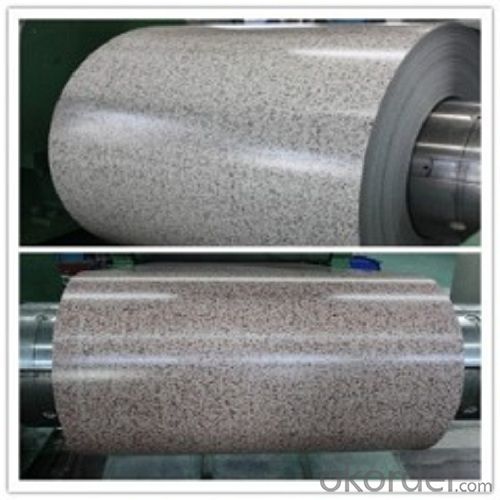

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: What are the advantages of using aluminum coils over other materials?

- There are several advantages of using aluminum coils over other materials. Firstly, aluminum is a lightweight material, making it easier to handle and transport. This lightweight nature also makes it more cost-effective as it requires less energy to manufacture and install. Secondly, aluminum has a high level of corrosion resistance. It does not rust, even when exposed to harsh environmental conditions, making it suitable for outdoor applications. This durability ensures a longer lifespan and reduces maintenance costs in the long run. Additionally, aluminum coils provide excellent heat transfer properties. They have a high thermal conductivity, allowing for efficient heat exchange. This makes them ideal for applications such as heating, ventilation, and air conditioning systems, where effective heat transfer is crucial. Moreover, aluminum is a highly recyclable material. It can be recycled repeatedly without losing its quality or performance. This not only reduces waste and contributes to environmental sustainability but also lowers production costs. Lastly, aluminum coils offer versatility in terms of design and customization. They can be easily formed, shaped, and coated to meet specific requirements. This flexibility allows for a wide range of applications in various industries, from automotive and construction to electronics and aerospace. Overall, the advantages of using aluminum coils, including its lightweight nature, corrosion resistance, heat transfer properties, recyclability, and versatility, make it a preferred choice over other materials.

- Q: Is it possible to utilize aluminum coil in the welding process?

- <p>Yes, aluminum coil can be used for welding. It is commonly used as a filler material in processes like MIG (Metal Inert Gas) welding, where it is fed continuously into the weld pool to create a joint. Aluminum welding requires specific techniques and equipment due to its high thermal conductivity and the need to prevent oxidation. The aluminum coil must be of high quality and clean to ensure a strong, corrosion-resistant weld.</p>

- Q: What are the rules and regulations regarding the use of aluminum coil in commercial kitchen settings?

- <p>Yes, there are regulations on the use of aluminum coil in commercial kitchens. These regulations often relate to food safety, hygiene, and the material's suitability for contact with food. Aluminum is generally safe for food contact, but it must meet specific standards to ensure it does not leach harmful substances into food. Regulations may vary by country or region, with some areas having strict guidelines on the types of aluminum alloys allowed and their intended use. Compliance with these regulations is crucial to avoid health risks and legal penalties. It's important for commercial kitchens to use food-grade aluminum and to follow local health department guidelines.</p>

- Q: What are the bending and forming capabilities of aluminum coils?

- Aluminum coils have excellent bending and forming capabilities due to their inherent flexibility and malleability. They can be easily bent, shaped, and formed into various complex shapes and designs without losing their structural integrity. This makes them highly versatile and suitable for a wide range of applications in industries such as construction, automotive, aerospace, and manufacturing.

- Q: I don't know, I see a metal is a metal. I understand that a bike shop bike has better service and the bike has better components. Yet I just feel the frame of a $500 bike store bike and a $100 bike from Walmart using aluminum is the same. It's like people charging $100 for audio/video cables when a $1 no-name cable works the same for tv. Is this the same marketing ploy in the bike industry?I see a Mongoose bike for $500 to $1000 on their website, yet I see one with the same frame metal at Walmart/Kmart for only $100. Mongoose is a reputable name. What gives?What do you think? Is the metal quality in a $500 aluminum bike shop bike the same as a $100 aluminum department store bike?

- Customer service is a very important reason to buy a bike shop quality bike. A bike shop will have staff who actually know something about bicycles. They will make sure the bike is the right size for you fits you comfortably. They won't mind changing over parts (such as a saddle or a stem) to make the bike has comfortable as possible. They provide a bike with a decent warranty (on both the frame components) some free bike check-ups from a qualified mechanic. The mechanics don't mind adjusting the bike gears brakes for you, usually free of charge. And they have a wealth of knowledge, and don't mind answerering any questions you may have. These are all very good reasons to not buy a bike at a walmart store. EDIT - The dual suspension on cheap bikes are usually not very good quality. Don't expect to be able to do any real mountain biking with that kind of bike. It'll also have low quality gears brakes. Be prepared to learn how to do basic adjustments maintenance yourself, so it stays roadworthy. The metal quality might be similar, but the welding will not be as good as more expensive bikes. And what's the point in having a good frame if the components are low quality. It's the components which make the bike function as a bike.

- Q: Can aluminum coils be used for cladding purposes?

- Yes, aluminum coils can be used for cladding purposes. Aluminum is a popular choice for cladding due to its durability, lightweight nature, and resistance to corrosion. The coils can be formed into various shapes and sizes, making them suitable for cladding applications in industries such as construction, architecture, and manufacturing.

- Q: Can aluminum coils be used in heat sinks?

- Yes, aluminum coils can be used in heat sinks. Aluminum is a commonly used material for heat sinks due to its excellent thermal conductivity properties, which allow it to efficiently transfer heat away from the source. The coil shape helps to increase the surface area, enhancing heat dissipation.

- Q: Is there any legislation or regulation governing the use of aluminum coils within specific industrial sectors?

- <p>Yes, there are regulations on using aluminum coils in certain industries. These regulations often vary by country and industry. For instance, in the food and beverage industry, aluminum coils may be subject to food safety standards to ensure they do not contaminate products. In construction, they might need to meet building codes and specifications for strength and durability. The aerospace industry has stringent regulations regarding the materials used in aircraft parts, including aluminum coils. Compliance with these regulations is crucial to ensure safety, quality, and to avoid legal penalties.</p>

- Q: Are aluminum coils resistant to fire?

- Yes, aluminum coils are generally resistant to fire due to their high melting point and low flammability.

- Q: Are aluminum coils suitable for food and beverage packaging?

- Yes, aluminum coils are highly suitable for food and beverage packaging. Aluminum is a safe and durable material that helps protect the quality and freshness of food and beverages. It is non-toxic, corrosion-resistant, and provides an effective barrier against moisture, oxygen, and light. Additionally, aluminum coils are lightweight, easily moldable, and can be easily shaped into various packaging formats, making it a popular choice for the food and beverage industry.

Send your message to us

1060 Anti-Corrosion Color Coated Aluminum Coil for Roofing and Cladding System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords