Aluminum Strip Coils for Metal Curtain Wall 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

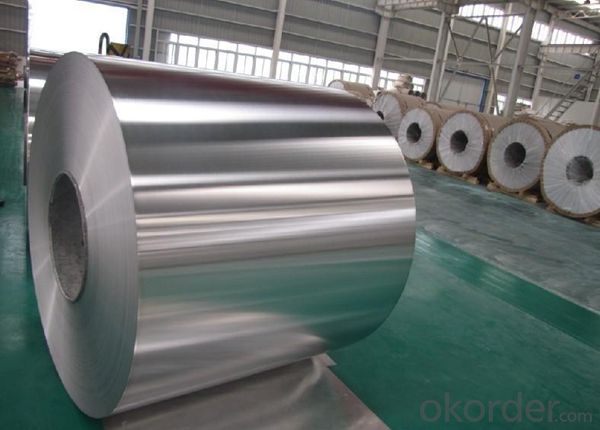

Aluminum Coil for Metal Curtain Wall 1XXX 3XXX 5XXX

1.Structure of Aluminum Coil for Metal Curtain Wall 1XXX 3XXX 5XXX

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminum Coil for Metal Curtain Wall 1XXX 3XXX 5XXX

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

3. Aluminum Coil for Metal Curtain Wall 1XXX 3XXX 5XXX Images

4.Specification of Aluminum Coil for Metal Curtain Wall 1XXX 3XXX 5XXX

Alloy Number | AA5XXX 1XXX 3XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ of Aluminum Coil for Metal Curtain Wall 1XXX 3XXX 5XXX

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Describe the various types of coatings applied to steel coils and their applications.

- <p>Steel coils can be coated with several different types of materials to enhance their properties for various applications. Common coatings include: 1) Galvanized coating, which provides corrosion resistance and is used in construction and automotive industries. 2) Pre-painted or color-coated steel, which is coated with organic paint and used for aesthetic purposes in buildings and appliances. 3) Aluminized coating, offering high-temperature resistance and used in heat-treating processes. 4) Zinc-iron alloy coating, which combines the benefits of zinc and iron for enhanced corrosion protection. 5) Organic coatings such as epoxy or polyurethane, used for specific chemical resistance or additional protection in harsh environments. Each type of coating is chosen based on the specific requirements of the end product and the environmental conditions it will face.</p>

- Q: What is the difference between hot-rolled and cold-rolled aluminum coils?

- The main difference between hot-rolled and cold-rolled aluminum coils lies in the production process. Hot-rolled aluminum coils are produced at high temperatures, which makes them more malleable and ductile. This process also results in a scaly surface finish. In contrast, cold-rolled aluminum coils are processed at lower temperatures, making them harder and more rigid. Cold-rolled coils have a smoother and more polished surface finish. Ultimately, the choice between hot-rolled and cold-rolled aluminum coils depends on the specific application and desired properties.

- Q: How are aluminum coils cut and shaped?

- Aluminum coils are cut and shaped using various methods and tools, depending on the desired shape and size. The most commonly used techniques include slitting, shearing, and laser cutting. Slitting is the process of cutting a wide coil into narrower strips. It involves feeding the coil through a set of circular blades that make precise cuts along the length of the coil. This method is commonly used to produce thin strips of aluminum that are then further processed or used in various applications. Shearing is another common method used to cut aluminum coils. It involves using a machine with a moving blade to cut through the coil. The blade applies pressure to the coil, resulting in a clean and straight cut. Shearing is often used for cutting thicker aluminum coils and is suitable for producing straight cuts without any deformation. Laser cutting is a more advanced technique used to cut and shape aluminum coils. It involves using a high-powered laser beam to melt or vaporize the metal along a predetermined path. This method offers high precision and allows for complex shapes and designs to be cut into the aluminum. Laser cutting is commonly used in industries where intricate and detailed cuts are required. After the cutting process, the aluminum coils can be further shaped using various methods such as bending, rolling, stamping, or forming. These techniques allow the aluminum to be shaped into different geometries and forms according to the specific requirements of the desired application. Overall, the cutting and shaping of aluminum coils involve a range of techniques and tools, each suited for different requirements. The chosen method depends on factors such as the thickness of the coil, the desired shape, and the precision needed for the final product.

- Q: Can aluminum coils be used for HVAC condenser coils?

- Yes, aluminum coils can be used for HVAC condenser coils. In fact, aluminum coils have become increasingly popular in recent years due to their numerous advantages over traditional copper coils. Aluminum coils are lighter, more durable, and more resistant to corrosion. They also have excellent heat transfer properties, allowing for efficient cooling of the refrigerant. Additionally, aluminum coils are more cost-effective and environmentally friendly compared to copper coils. Overall, using aluminum coils for HVAC condenser coils is a viable and beneficial option.

- Q: If you were to make something from each of these.which is more expensive? aluminum or carbon fiber ?which is stronger?What would the advantages or disadvantages of each be?

- Aluminum Vs Carbon Fiber

- Q: Are aluminum coils suitable for soundproofing applications?

- Typically, soundproofing applications do not involve the use of aluminum coils. Although aluminum is an effective conductor of heat and electricity, it lacks the sound-dampening properties found in other commonly used soundproofing materials like foam, rubber, or dense fibers. These materials are designed to absorb and block sound waves, thereby reducing noise transmission. Conversely, aluminum coils are commonly utilized in HVAC systems or as a building exterior material due to their durability and heat transfer capabilities. Consequently, if the primary goal is soundproofing, it is advisable to explore alternative materials specifically engineered for that purpose.

- Q: I know when you stick weld aluminum you're more brazing than actually welding but i was just wondering about this, i want some electrodes just in case i need a temporary repair. Also what Amperage should i run it at,and what polarity?? my friend told me to run hotter than usual but hes only 14, and I dont know how reliable he is. Im 14 by the way also and have been welding for two years now and im always out running around the ranch doing small repairs. thanks ahead of time!

- yep, okorder .

- Q: Can aluminum coils be used in food packaging?

- Yes, aluminum coils can be used in food packaging. Aluminum is a popular choice for food packaging due to its excellent barrier properties, lightweight nature, and ability to maintain the freshness and quality of food products. It is widely used in various forms, including coils, for packaging food items like beverages, snacks, and canned goods.

- Q: How are aluminum coils used in the aerospace industry?

- Aluminum coils are extensively used in the aerospace industry for various applications. One of the primary uses of aluminum coils is in the construction of aircraft structures. Aluminum is a lightweight material with excellent strength-to-weight ratio, making it an ideal choice for the aerospace industry where weight reduction is crucial. These coils are often formed into sheets or plates and used to build aircraft fuselage, wings, and other structural components. In addition to structural applications, aluminum coils are also used in the manufacturing of heat exchangers and cooling systems in aircraft. Aluminum's high thermal conductivity and corrosion resistance make it an excellent material for dissipating heat generated by engines and electronic systems. The coils can be shaped into tubes or fins, allowing efficient heat transfer and ensuring optimal performance of the aircraft's cooling systems. Another important use of aluminum coils in the aerospace industry is for electrical applications. Aluminum is a good conductor of electricity, and its coils are used in the production of electrical wiring, connectors, and cables. These components are crucial for the proper functioning of various systems in an aircraft, including power distribution, communication, and navigation systems. Furthermore, aluminum coils are also employed in the construction of fuel tanks and hydraulic systems in aircraft. Aluminum's resistance to corrosion and its ability to withstand high pressure and temperature make it a reliable choice for these critical components. The coils can be shaped and welded to form tanks or piping systems that store and transport fuel and hydraulic fluids safely and efficiently. Overall, aluminum coils play a vital role in the aerospace industry by providing lightweight, strong, and corrosion-resistant materials for structural, thermal, electrical, and fluid management applications. Their versatility, durability, and excellent performance characteristics make them indispensable in the design and construction of modern aircraft, ensuring safety, efficiency, and reliability in air transportation.

- Q: What are the common sizes of aluminum coils used in roofing?

- The common sizes of aluminum coils used in roofing can vary depending on the specific needs and requirements of the project. However, some popular sizes include 24-inch, 36-inch, and 48-inch widths. These sizes are often chosen for their compatibility with standard roofing systems and their ability to cover a wide surface area efficiently. Additionally, the thickness of the aluminum coil can also vary, with common options ranging from 0.019 inches to 0.032 inches. Ultimately, the size of the aluminum coil used in roofing will depend on factors such as the size of the roof, the desired aesthetic, and the local building codes and regulations.

Send your message to us

Aluminum Strip Coils for Metal Curtain Wall 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords