125 Aluminum Sheets in Spfd Mo for Sale - Aluminum Boat for Fishing with Different Sizes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

| Place of Origin: | Shandong, China (Mainland) | Brand Name: | Allheart | Model Number: | HT625 |

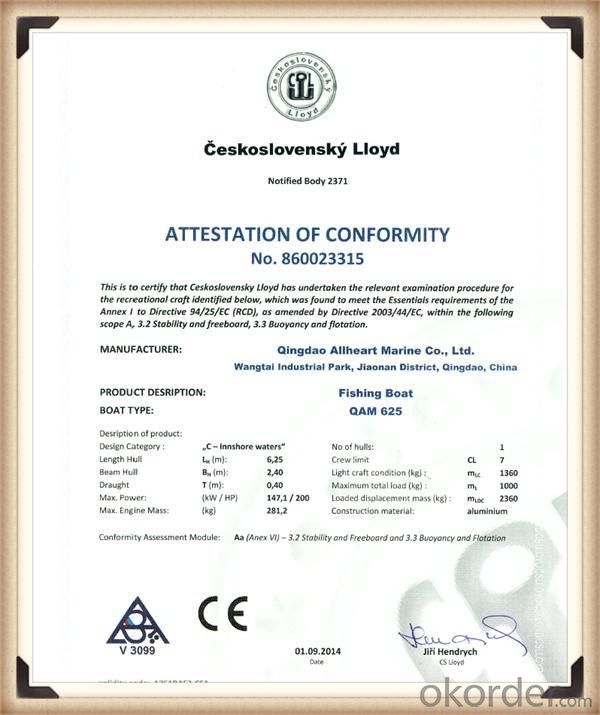

| Hull Material: | Aluminum | Certification: | CE | Capacity (Person): | 10 |

| Length: | 6.25-8m | color: | optional |

Packaging & Delivery

| Packaging Details: | 1)Fishing Boat package according to export standard 2)Fishing Boat package based on seaworthy standard 3)Special package as customer's request |

| Delivery Detail: | within 45 days after 30% deposit |

6.25m cuddy cabin | ||

SPECIFICATIONS | STANDARD FEATURES | STANDARD FEATURES |

Length of Hull: 6.25m | 3 Years Warranty | Seat: Ocean Pro & box storage |

Beam: 2.3m | Rear Ladder | Cleat on Front Deck |

Depth: 1.45m | Windscreen | Floor: Front Casting Platform |

Sides:4mm | Rod Holders (4) | Rail: Transom & Cabin Grabrail |

Bottomsides: 5.00mm | Bollard/Boweye | Rail:Long Side Rails & Low Bowrails |

Topsides: 4.00mm | Anchorwell | Transducer Brackets x 2 |

Transom Material: 5.00mm | Cabin and hard Top | Seat: Cabin Cushions |

Transom Shaft Length: L/L | Double chimes | Cleat On Transom Corners |

Weight (boat only):1155kg | Carpet wooden floor | Twin Battery Box & Switch |

Rec. HP: 150hp | TMC bilge pump | Underfloor Fuel Tank 200 Litres |

Max. HP: 200hp | Under the floor flotation | Seat: Folding Rear Lounge |

Main Motor Weight: 315kg | Cutting Board (Alloy) | fishing tank 60L |

umber of People (Level): N/A | Self Drain Floor Treadplate | Trim Tabs |

Number of People: 8 | Side Pockets (2) | Bait tank 30L |

FAQ

Q: What models do you have available?

A: We currently offer the following layouts for the 498 Series:

Angler 498A - Side Console Boat

Bay Fisher 498F - Center Console Boat

Bay Rover 498R - Runabout Boat

Sports Cuddy 498S - Cuddy Cabin Boat

We also offer 4.6m versions of these boats, they are identical except for the twin rear swimming platforms.

Q: I want to see the boats in person, where can I find them?

A: We have showrooms in Japan (Osaka), Australia (Sydney, Brisbane and Melbourne), and other countries. Please see our website at www.MorningstarBoats.com for a complete list. We are also happy to organize factory tours for you if you would like to come to Taiwan for a visit.

Q: Could you pre-install outboard engines for me?

A: Yes, we can provide Mercury and Evinrude outboards, from 40HP to 115HP.

Q: Could you provide boat trailers?

A: Yes, we have boat trailers specially designed for our aluminum boat hulls.

Q: Do I need drainage for my boat?

A: Aluminium floor without drainage is like most small boats, when you moor it in the harbour and it keeps raining, water will start to accumulate. Once the water level from under the deck is high enough, the automatic bilge pump will be triggered and starts pumping out water.

Our Services

We provide the following products:

14ft, 15ft, 16ft and 17ft aluminum luxury boats (4.6m ~ 4.98m). This is our most popular range.

10ft, 11ft, 12ft, and 13ft small aluminum fishing boats (car toppers and open boats, 3.2m ~ 4.1m) Guranteed low prices!

5.5m Rigid-Hulled Inflatable Boats (RIBs) with aluminum hulls

We provide many customization options.

Contact us NOW for the best boat money can buy!

- Q: I am trying to find away of turning aluminum oxide or alumina into just aluminum. Please post all ideas i dont care how crazy.

- usually, in industy, the common way used is electrolysis...aluminium oxide, Al2O3 is heated until it's molten...then cryolite is added to bauxite (aluminium oxide) to lower its melting point before electrolysis is carried out to obtain pure Al metal...

- Q: What are the advantages of using aluminum sheet in construction?

- There are several advantages to using aluminum sheet in construction. Firstly, aluminum is a lightweight material, making it easier to handle and transport on construction sites. This reduces the need for heavy machinery and equipment, resulting in cost savings and improved efficiency. Secondly, aluminum has excellent corrosion resistance properties. Unlike other metals, such as steel, aluminum does not rust or corrode when exposed to moisture or harsh weather conditions. This makes it highly durable and suitable for outdoor applications, such as roofing or cladding. Additionally, aluminum is a highly versatile material that can be easily shaped and formed into different sizes and profiles. This allows for greater design flexibility, enabling architects and engineers to create innovative and unique structures. Moreover, aluminum is a sustainable material. It is 100% recyclable, meaning that it can be reused indefinitely without any loss in quality or performance. This makes it an environmentally friendly choice for construction projects, as it helps reduce waste and minimize the carbon footprint. Furthermore, aluminum has excellent thermal and electrical conductivity properties. It reflects heat and light, helping to maintain comfortable indoor temperatures and reduce energy consumption. It is also an excellent conductor of electricity, making it ideal for electrical wiring and components in buildings. Lastly, aluminum is a cost-effective material in the long run. Although it may have a higher initial cost compared to other building materials, its low maintenance requirements and long lifespan offset these costs over time. It does not require painting or regular upkeep, saving both time and money in the maintenance and repair of structures. In conclusion, the advantages of using aluminum sheet in construction include its lightweight nature, corrosion resistance, versatility, sustainability, thermal and electrical conductivity, and cost-effectiveness. These qualities make it a highly desirable material for a wide range of construction applications.

- Q: what is aluminum pigment paint in the scratch cards of lottory?is it metalic or organic sabstance like latex?

- Yes its aluminium metal. Finely divided aluminium powder is dispersed in a polymer resin as used for paint.

- Q: This question asks for methods to protect aluminum sheets from damage during transportation and storage.

- <p>To prevent damage to aluminum sheets during transportation or storage, follow these guidelines: 1) Use protective packaging such as bubble wrap or padded covers to prevent scratches and dents. 2) Store aluminum sheets in a dry, cool place away from moisture and direct sunlight to avoid corrosion. 3) Stack sheets with soft padding between them to prevent surface damage. 4) Securely strap or brace the sheets during transport to prevent movement and potential damage. 5) Handle aluminum sheets with clean, dry hands or use gloves to avoid leaving fingerprints or oils that can cause corrosion. 6) Ensure that transportation vehicles are clean and dry to prevent any contaminants from coming into contact with the aluminum. By adhering to these practices, you can minimize the risk of damage to aluminum sheets.</p>

- Q: How does the surface treatment of aluminum sheet affect its appearance?

- The surface treatment of aluminum sheet can greatly affect its appearance. Different treatments such as anodizing, coating, or polishing can alter the texture, color, and shine of the aluminum surface. Anodizing can create a protective oxide layer while also providing a range of colors. Coatings can add a layer of paint or protective film, giving the aluminum a smooth or textured finish and providing various color options. Polishing can enhance the reflectivity of the aluminum, giving it a shiny and mirror-like appearance. Overall, the surface treatment plays a crucial role in determining the final look and visual appeal of the aluminum sheet.

- Q: Is this aluminium plate ceiling dark keel or bright keel?

- I see you're a layman...... Where is the ceiling keel now?.... Now they are made of dark keel, so it's better to look at comfort, and we need to go through the lines and some pipes

- Q: Can aluminum sheets be used for outdoor furniture?

- Yes, aluminum sheets can be used for outdoor furniture. Aluminum is a popular choice for outdoor furniture due to its durability, lightweight nature, and resistance to rust and corrosion. It is commonly used to make outdoor tables, chairs, and other furniture pieces.

- Q: What are the physical properties of aluminum sheets?

- Aluminum sheets possess several physical properties, including being lightweight, corrosion-resistant, and having a high strength-to-weight ratio. They are also ductile, meaning they can be easily shaped or formed without breaking. Additionally, aluminum sheets have excellent thermal and electrical conductivity, making them suitable for various applications in industries such as construction, aerospace, and automotive.

- Q: Are aluminum sheets suitable for architectural louvers?

- Indeed, aluminum sheets prove to be a fitting option for architectural louvers. The advantageous properties of aluminum make it a favored material for louvers in the field of architecture. To begin with, aluminum possesses the desirable combination of being lightweight and yet sturdy, which makes it an ideal material for architectural louvers. It has the ability to withstand external forces such as wind and various weather conditions while maintaining its structural integrity. This becomes crucial for louvers as they are required to provide ventilation and airflow, all the while retaining their form and functionality. Furthermore, aluminum displays a high level of resistance against corrosion and rust. Considering that louvers are frequently exposed to outdoor elements like rain, moisture, and sunlight, the corrosion resistance of aluminum ensures the longevity and durability of the louvers, even in harsh environmental conditions. In addition, aluminum is an adaptable material that can be easily customized and fabricated into different shapes and sizes. This flexibility allows architects and designers to fashion louvers with unique designs and configurations that suit the specific requirements of the building. Aluminum louvers can be personalized to optimize airflow, control light, and enhance aesthetic appeal. Moreover, aluminum stands out as a sustainable and environmentally friendly material. It is widely recyclable, which means that aluminum louvers can be easily repurposed or reused at the end of their life cycle. Opting for aluminum in the construction of architectural louvers aligns with sustainable building practices and contributes to the overall reduction of environmental impact. In conclusion, aluminum sheets are indeed a suitable choice for architectural louvers. Their lightweight yet robust nature, resistance to corrosion, ability to be customized, and sustainability make them an excellent option in terms of functionality, durability, and aesthetics.

- Q: Are 101 aluminum sheets suitable for medical equipment?

- No, 101 aluminum sheets are not suitable for medical equipment. Medical equipment requires materials that are highly durable, corrosion-resistant, and have excellent biocompatibility. While 101 aluminum is a strong and versatile alloy, it does not possess the necessary characteristics for medical equipment. Instead, medical equipment manufacturers typically use specialized alloys such as stainless steel or titanium, which offer superior strength, resistance to corrosion, and compatibility with the human body. It is essential to prioritize the safety and effectiveness of medical equipment by selecting appropriate materials that meet the specific requirements of the healthcare industry.

Send your message to us

125 Aluminum Sheets in Spfd Mo for Sale - Aluminum Boat for Fishing with Different Sizes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords