Decorative Color Coated Aluminum Sheets for Boat Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

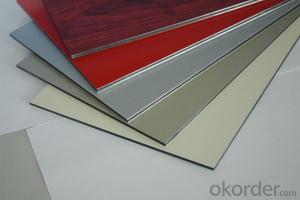

1.Structure of Color Coated Aluminium Foils for Decoration Package

Color Coated Aluminium Foils for Decoration Package is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Color Coated Aluminium Foils for Decoration Package

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

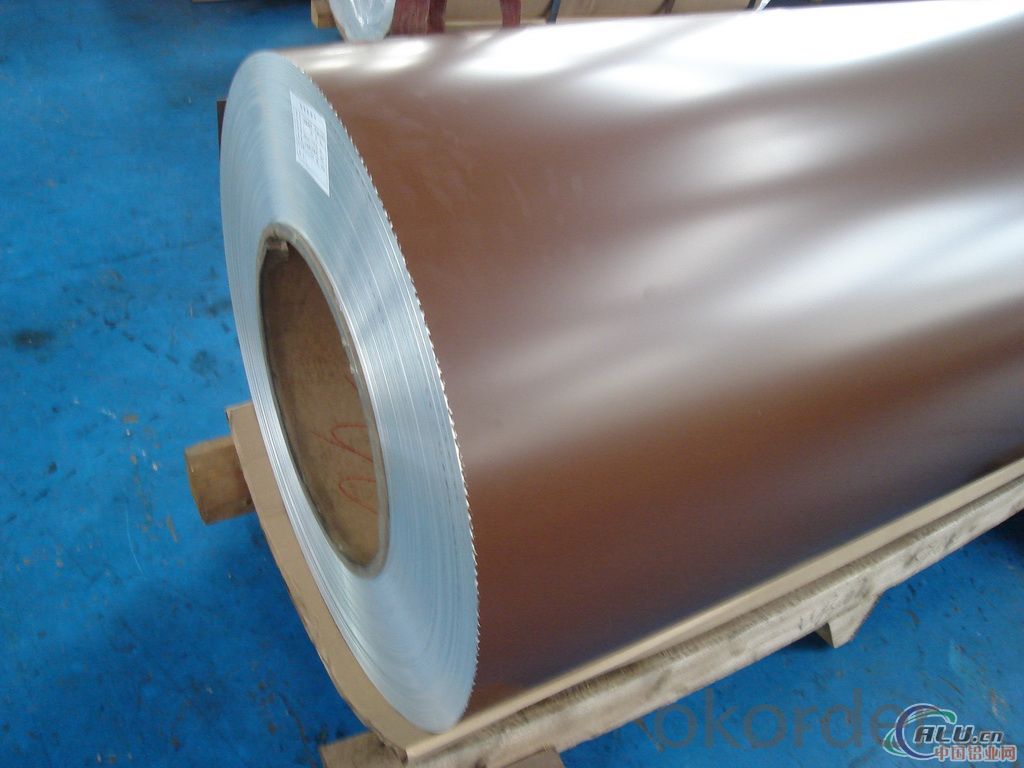

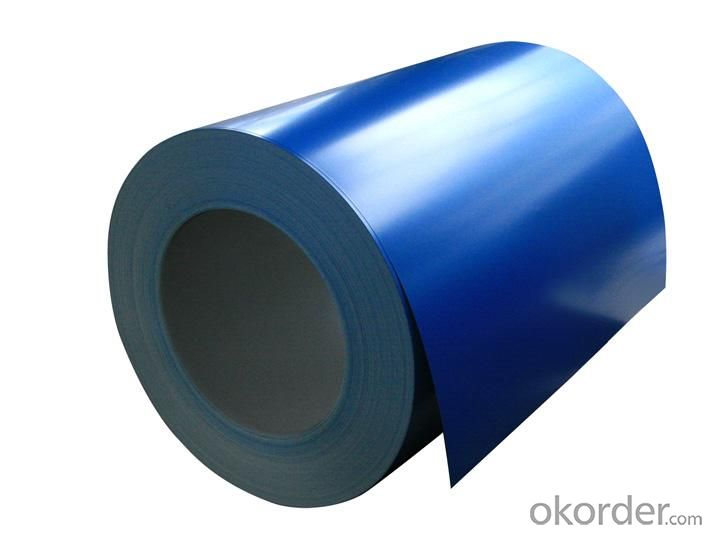

3. Image of Color Coated Aluminium Foils for Decoration Package

4. Product Specification of Color Coated Aluminium Foils for Decoration Package

| ALLOY | TEMPER | COATING | COATING THICKNESS | WEIGHT |

| AA3003 | H18 | PE | 22-25 MICRONS | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What is the lifespan of an aluminum sheet?

- The lifespan of an aluminum sheet can vary depending on various factors such as the thickness of the sheet, the quality of the aluminum, and the conditions it is exposed to. However, under normal circumstances, aluminum sheets can last for several decades or even longer if properly maintained and protected from corrosion.

- Q: Can you make tank armor using Aluminium, Polymers, Styrofoam, Explosive Reactive Armor to stop NATO DP rounds and/or HEAT rounds maybe RPG-7?

- Aluminium has a strength up to 800 N/mm2 (for its best Al-based alloys) while steels can go much higher... about 1400 N/mm2 if I recall well. The problem with aluminium is that is prompt to fatigue break which is not good with something vibrating like a rolling tank armor. Polymers are not strong enough unless you use composite materials, for ex. fibre glass or even better - carbon fibre reinforced. The problem is still that unlike steel, the strength is exceptionally high... in one direction - so pray for the impact to be mostly from this direction.

- Q: This question asks about the various types of paint that can be used specifically for aluminum sheets, indicating an interest in paint compatibility and options for this particular material.

- <p>There are several types of paints suitable for aluminum sheets, each offering unique properties. These include: 1. Acrylic Paints - Water-based, easy to apply, and offer good adhesion. 2. Epoxy Paints - Known for their durability and chemical resistance, they provide a strong bond to the metal. 3. Enamel Paints - Provide a hard, glossy finish and are resistant to chipping and scratching. 4. Polyester Paints - Offer excellent durability and UV resistance, making them suitable for exterior applications. 5. Powder Coatings - Applied electrostatically, they provide a tough, scratch-resistant finish. 6. Specialty Paints - Such as heat-resistant or anti-corrosive paints, designed for specific industrial applications. The choice of paint depends on the application, desired finish, and environmental conditions.</p>

- Q: on an hot day, which will stay cooler longer...aluminum, or copper? why?thanks!

- Aluminum conducts heat faster than copper, so if both are left in the sun, the copper will stay cooler longer. When they are removed from the sunlight, the aluminum will become cooler first.

- Q: Nissan A1100P aluminum plate is equivalent to what brand of domestic, where there are relevant information and instructions, mechanical design manuals or other materials manuals? Thank you.

- Other process properties are basically the same as those of 1050A. 1100 commonly used to have good machining performance, high corrosion resistance, high strength does not need not see, such as video and chemical handling and storage equipment, sheet metal products, hardware, hollow spinning drawing goods welding key combination, reflector, nameplate.

- Q: Are the aluminum sheets suitable for manufacturing electrical busbars?

- Indeed, electrical busbars can be manufactured using aluminum sheets. The remarkable electrical conductivity and lightweight nature of aluminum render it a preferred option for busbars. It effectively carries substantial electrical currents and boasts low resistance, making it exceptionally suitable for transporting electricity in power distribution networks. Moreover, aluminum sheets can be effortlessly manipulated and molded into diverse forms and dimensions, granting the opportunity for personalized designs and streamlined integration into electrical systems.

- Q: Are aluminum sheets suitable for medical equipment?

- Medical equipment can indeed utilize aluminum sheets. Aluminum, a lightweight and durable metal, is highly resistant to corrosion, making it a popular choice in the manufacturing of medical equipment. Surgical instruments, diagnostic tools, and patient monitoring systems all benefit from the use of aluminum. The malleability of aluminum sheets allows for the creation of intricate designs in medical equipment fabrication. Furthermore, aluminum is non-toxic and non-magnetic, both of which are crucial qualities in medical environments. Its ability to withstand sterilization processes, like autoclaving, only adds to its suitability for medical equipment. Overall, aluminum sheets prove to be a dependable and adaptable material for the production of medical equipment.

- Q: I have a project on the aluminum element. What are the advantages and disadvantages of this element?...What are the risks/dangers?...Thank you so much ---And please tell me where I could find this information too.

- Disadvantages: * Far more expensive that steel. * Limited to certain geometric features using economical processes. * Abrasive to tooling (aluminum oxide is very abrasive). * Difficult to weld. * Prone to severe spring back. Advantages: Aluminum is the preferred choice for fencing due to several inherent advantages of aluminum. The main advantage is that aluminum components do not rust as easily as iron. Aluminum fences are given a powder-coat finish that protects the surfaces. This kind of a finish also enhances its appearance and provides a smooth surface for painting, if desired. All the components of the fence are drilled and powder-coated prior to assembly. Extreme care is taken during assembly by using sturdy fasteners, brackets, and rivets. Wherever these fasteners, etc., need to be visible, attractive stainless steel ones are used. This provides both looks and strength. As aluminum is an easy metal to work with, a plethora of style choices and adornment options are made available to clients. The flexibility of the metal allows for several designs that can complement the facade of the structure they are installed around.

- Q: Can aluminum sheets be an alternative to glass in certain applications?

- Yes, aluminum sheets can be an alternative to glass in certain applications. Aluminum is lightweight, durable, and has excellent corrosion resistance, making it suitable for outdoor and industrial applications where glass may be prone to breakage or damage. Additionally, aluminum sheets can provide better insulation and soundproofing properties compared to glass. However, it is important to consider specific requirements and limitations of each application before choosing aluminum sheets as an alternative to glass.

- Q: What is the reflectivity of aluminum sheets?

- The reflectivity of aluminum sheets is quite high, typically ranging from 80% to 95%, which makes them excellent for various applications that require high levels of reflection, such as mirrors, solar panels, and decorative surfaces.

Send your message to us

Decorative Color Coated Aluminum Sheets for Boat Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords