Printable Aluminum Sheets AA1050/AA1100 for Aluminum Boats

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Sheets

Thickness | 0.2mm-8mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm |

Width | 20mm-2500mm |

inner diameter | 76mm / 152mm |

Material | AA1050, AA1060, AA1070, AA1100, AA1235, AA3003, AA3004, AA3005, AA5052, AA5005, AA5754, AA5083, AA8011, AA8079, etc |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38, |

Surface | Mill finish / Coated |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 30-35 days after the receiving L/C or deposit |

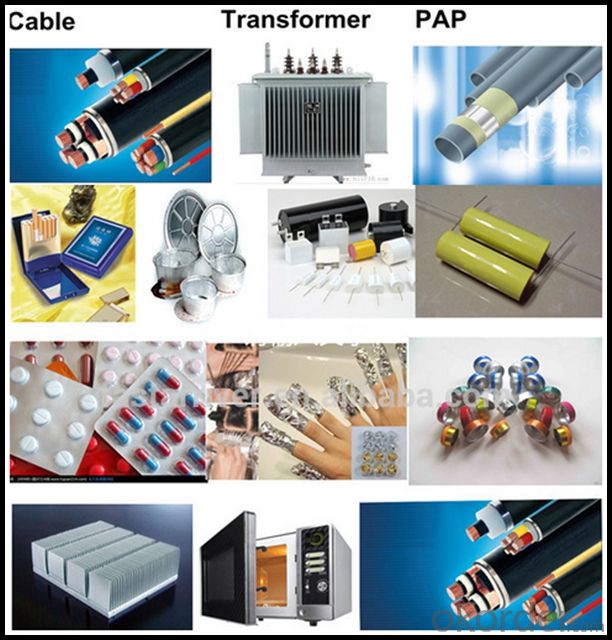

2. Application of Aluminum Sheets

(1) Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors, windows,

(2) Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations.

(3).Advertisement: display platforms, signboards, fascia, shop fronts.

3. Feature of Aluminum Sheets

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificates:

SGS and ROHS (if clients request, paid by client), MTC (plant provided), Certificate of Origin (FORM A, FORM E, CO), Bureau Veritas (if client request, paid by client), CIQS certificate and so on.

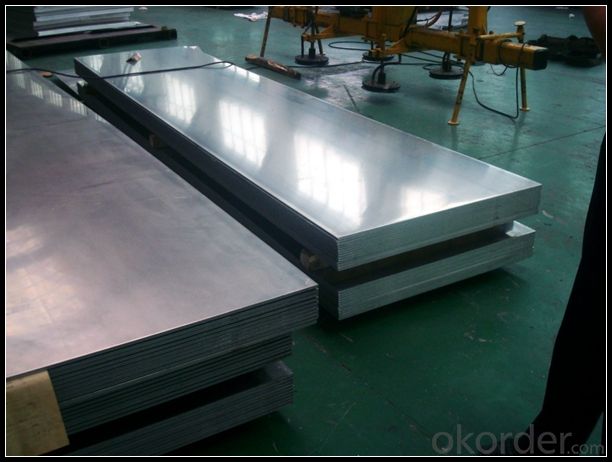

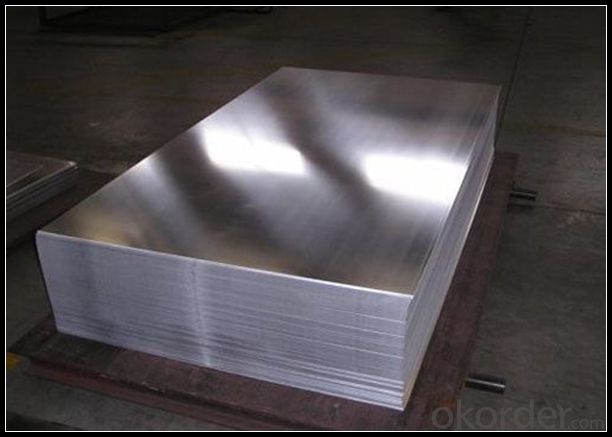

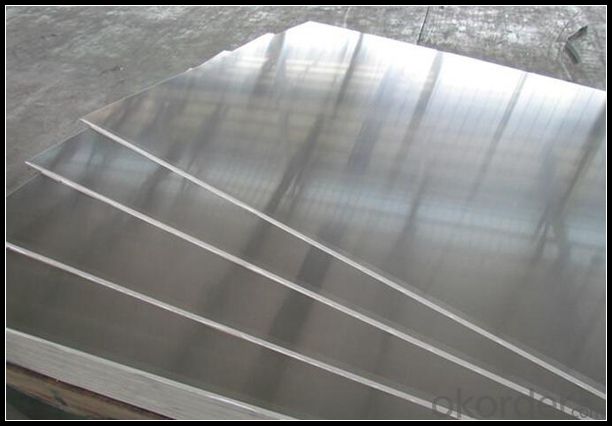

5. Image of Aluminum Sheets

6. Package and shipping of Aluminum Sheets

Eye to wall

Eye to the wall

With wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Depends on actual order, around 30 to 35 days

2) What is the QC system?

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the main influence of the spacing?What are the main effects of spacing?

- No specific requirements this is mainly based on the actual condition is decided from the basic glass 2-5 cm bar to say what is the effect of the distance away from the glass I guess few people considered but I feel far and near to the overall effect is very small but I feel close the glass produced heat explosion probability will be reduced...

- Q: What is the typical modulus of elasticity of aluminum sheets?

- The typical modulus of elasticity of aluminum sheets varies depending on the alloy and temper. However, a commonly used value is around 70 GPa (gigapascals) or 10 million psi (pounds per square inch). This value represents the stiffness or rigidity of the material, indicating its ability to withstand deformation under applied stress. It is important to note that different grades and conditions of aluminum may have slightly different modulus of elasticity values, so it is recommended to consult the specific material specifications for accurate information.

- Q: What are the common sizes of aluminum sheet?

- Some common sizes of aluminum sheet include 4x8 feet (48x96 inches), 4x10 feet (48x120 inches), and 5x10 feet (60x120 inches).

- Q: Can aluminum sheets be used for HVAC systems?

- Yes, aluminum sheets can be used for HVAC systems. Aluminum is a popular material choice for HVAC applications due to its many advantageous properties. It is lightweight, making it easier to handle and install. Aluminum is also highly resistant to corrosion, which is crucial for HVAC systems that are exposed to moisture and varying temperatures. Additionally, aluminum has excellent thermal conductivity, allowing for efficient heat transfer. This makes it ideal for heat exchangers and other components in HVAC systems. Overall, aluminum sheets are a reliable and durable option for HVAC systems.

- Q: Are aluminum sheets suitable for architectural applications?

- Yes, aluminum sheets are highly suitable for architectural applications. Aluminum is known for its lightweight yet strong properties, making it ideal for constructing various architectural elements such as roofing, cladding, windows, doors, and façades. It is corrosion-resistant, durable, and offers excellent thermal and electrical conductivity. Additionally, aluminum can be easily formed, bent, and fabricated, allowing architects to create intricate designs and shapes. Its versatility, aesthetic appeal, and sustainability make aluminum sheets a popular choice in the architectural industry.

- Q: Are 101 aluminum sheets suitable for conductive heat transfer applications?

- No, 101 aluminum sheets are not suitable for conductive heat transfer applications as they do not have good thermal conductivity properties.

- Q: Can aluminum sheets be bent without breaking?

- Yes, aluminum sheets can be bent without breaking. Aluminum is a highly malleable metal, which means it can be easily shaped and bent without fracturing or breaking. However, the degree of bendability may vary based on the thickness and alloy composition of the aluminum sheet.

- Q: Can aluminum sheets be embossed?

- Yes, aluminum sheets can be embossed.

- Q: i added aluminum sulfate to the soil from the bag with out mixing it with water and my hydrangeas look very sad. It burned them i guess... What is best thing to do to take some of it out or all if i can? will adding large amounts of water to the soil help it clear or will it make it worse? please before they die!!!10points!!!

- how much did you add i mix it with the soil for my hydrangeas and never have a problem.. blend it into the soil around the hydrangeas the burning you see may be related to something other than the aluminum sulfate

- Q: I am engaged in line cutting, because the cut aluminum plate conductive block wear more fierce, molybdenum wire is often broken card, I do not know that heroes have unique skills, say, we share. Thanks.

- Wire cutting is electrical discharge machining, which is developed on the basis of EDM, punching and forming. In some ways, EDM has been replaced by electrical discharge drilling. The processing object can be as long as the conductive metal parts. Cutting aluminum plate, steel plate effect is basically the same, but the cutting speed is different.

Send your message to us

Printable Aluminum Sheets AA1050/AA1100 for Aluminum Boats

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords