Aluminum Sheets in North Dakota - Aluminum Bar Flat Welding with Aluminum Rod Bar for Aluminum Grating

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

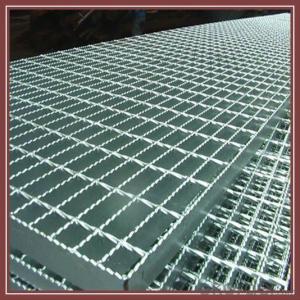

1.Description of Drainage trench cover:

Drainage trench cover is widely used in the urban road, the square, the botanical garden, the wharf, the airport, the parking lot, the road, each kind of industry, the civil project, etc.

2.Main features of Drainage trench cover:

I--Carrying 20 tons of weight

II—Carrying 14 tons of weight

III---carrying 6 tons of weight

IV---carrying 2 tons of weight

V---Carrying pedestrian weight

3.Glass Wool Blanket Images:

4. Drainage Trench Cover Technical Parameters:

These drain cover plate applies to the road cross-sectional and longitudinal drain. The drains width ranging from 200mm to 550mm.

A means the steel grating length

H means the steel grating height

A means the frame length

H means the frame height

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Drainage trench cover is

one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the advantages of using aluminum sheet in construction?

- Using aluminum sheet in construction offers several benefits. Firstly, its lightweight composition makes it easy to handle and transport on construction sites, reducing the need for heavy machinery and improving efficiency, ultimately leading to cost savings. Secondly, aluminum exhibits exceptional resistance to corrosion, unlike other metals such as steel, making it a durable and suitable material for outdoor applications like roofing or cladding. Additionally, aluminum's versatility allows for easy shaping and forming into various sizes and profiles, providing architects and engineers with greater design flexibility to create innovative and unique structures. Moreover, aluminum is a sustainable choice as it is 100% recyclable, helping reduce waste and minimize the carbon footprint. Furthermore, it possesses excellent thermal and electrical conductivity properties, reflecting heat and light to maintain comfortable indoor temperatures and reduce energy consumption. It also serves as an excellent conductor of electricity, making it ideal for electrical wiring and building components. Lastly, though aluminum may have a higher initial cost, its low maintenance requirements and long lifespan make it cost-effective in the long run. Structures made with aluminum sheet do not require regular painting or upkeep, saving both time and money. In conclusion, the advantages of utilizing aluminum sheet in construction encompass its lightweight nature, corrosion resistance, versatility, sustainability, thermal and electrical conductivity, and cost-effectiveness, making it highly desirable for a wide array of construction applications.

- Q: How do you prevent warping of aluminum sheets during bending?

- One way to prevent warping of aluminum sheets during bending is by using proper techniques and tools. This includes using the correct bending radius, ensuring even distribution of pressure along the sheet, and employing a suitable clamping method to hold the sheet in place during the bending process. Additionally, preheating the aluminum sheet can help to reduce the likelihood of warping.

- Q: What are the different methods of surface coloring aluminum sheets?

- There are several different methods to surface color aluminum sheets, each with its own advantages and limitations. Some of the most common methods include anodizing, powder coating, and painting. 1. Anodizing: Anodizing is a popular method for coloring aluminum sheets. It involves creating a controlled oxide layer on the surface of the aluminum through an electrochemical process. This oxide layer can be dyed in various colors, providing a durable and long-lasting finish. Anodized aluminum is resistant to corrosion, UV rays, and scratching, making it ideal for outdoor applications. 2. Powder coating: Powder coating is another widely used method for coloring aluminum sheets. It involves applying a dry powder coating to the surface of the sheet, which is then cured in an oven. The powder melts and forms a protective layer that adheres to the aluminum. Powder coating offers a wide range of colors and finishes, and it provides excellent durability, resistance to fading, and protection against scratches. 3. Painting: Painting is a traditional method of coloring aluminum sheets. It involves applying a liquid paint to the surface, which then dries and forms a protective layer. Painting offers a vast array of color options and can be used to achieve different finishes, such as matte, gloss, or metallic. However, painted aluminum sheets may require additional protective coatings to enhance durability and resistance to fading. 4. Cladding: Cladding is a technique that involves applying a thin layer of colored material, such as stainless steel, copper, or composite panels, to the surface of the aluminum sheet. This method allows for a wide range of colors and finishes, and it provides additional protection to the aluminum. Cladding can be used to achieve a unique aesthetic or to enhance the durability of the aluminum sheet. 5. Dye sublimation: Dye sublimation is a specialized method of coloring aluminum sheets that involves transferring designs or images onto the surface using heat and pressure. This process allows for high-resolution prints and vibrant colors, making it popular for decorative and signage applications. Each method of surface coloring aluminum sheets has its own advantages and considerations, such as durability, aesthetics, cost, and application requirements. It is important to carefully evaluate these factors to determine the most suitable method for a specific project.

- Q: Are aluminum sheets suitable for interior design applications?

- Yes, aluminum sheets are suitable for interior design applications. Aluminum is a versatile and durable material that can be used in various ways to enhance the aesthetics of interior spaces. It can be easily shaped, cut, and manipulated to create unique and modern designs. Aluminum sheets are available in different finishes, such as brushed, polished, or textured, which allows for a wide range of design possibilities. One of the main advantages of using aluminum sheets in interior design is their lightweight nature. This makes them easy to handle and install, reducing labor and transportation costs. Additionally, aluminum is resistant to corrosion, making it suitable for areas with high humidity or moisture, such as bathrooms or kitchens. Aluminum sheets can be used for various applications in interior design, including wall cladding, ceiling panels, room dividers, furniture, and decorative elements. They can be painted or coated in different colors to match any interior design scheme. Aluminum sheets can also be perforated or engraved to create patterns or intricate designs, adding a unique visual appeal to the space. Furthermore, aluminum is a sustainable material as it is highly recyclable. Its recycling process requires only a fraction of the energy needed to produce new aluminum, making it an eco-friendly choice for interior design applications. In conclusion, aluminum sheets are highly suitable for interior design applications due to their versatility, durability, lightweight nature, resistance to corrosion, and ability to be shaped and manipulated. They offer a wide range of design possibilities and can be used for various applications, making them a popular choice among designers and architects.

- Q: I am looking for info on grades of aluminum like 3003, 5053, 6160 what's the differance witch one are cheaper and weld easy please explain

- Grades okorder /

- Q: What type of aluminium sheet is a food grade?

- Pure aluminum, alloy aluminum can be. However, the majority of pure aluminum. Used by customers.

- Q: Aluminum knowledge. What is the model 3003 H24? What does H mean?

- 3003 is aluminium manganese alloy aluminum plate (Al--Mn), which is mainly composed of manganese.H24: continuous casting, continuous rolling, Zhang Liqiang and partial toughening.Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more). Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.Aluminium alloy is added in the process of aluminum alloy elements (main alloying elements copper, silicon, magnesium, zinc, manganese, minor alloying elements such as nickel, iron, chromium, titanium, lithium, etc.) in order to improve the mechanical properties of aluminum and chemical index. Alloy aluminum sheet has some special properties of pure aluminum plate, and is widely used in special environment, such as ship, refrigerator, mould, aerospace equipment, etc..

- Q: I have to repair a cracked aluminum engine block. What alumunum epoxy should I use?

- elmers glue! Lol. I believe you can have it welded. That will last for a while.or until you can get another one.

- Q: Is it possible to apply paint to an aluminum sheet roof after it has been installed?

- <p>Yes, you can paint your aluminum sheet roof after installation. However, it's crucial to ensure the surface is clean and free of any contaminants. Use a primer specifically designed for aluminum to enhance adhesion and durability. Apply a high-quality paint suitable for metal surfaces, following the manufacturer's instructions carefully. This process can help protect the roof from weathering and enhance its appearance, but it's recommended to consult with a professional to ensure the best results and longevity of the paint job.</p>

- Q: I just bought a cheap brand of pop tarts. One of the listed ingredients under Leavening is, sodium aluminum. I don't think Wal-Mart will take back the box, so should I just throw the whole box of 16, away. Or is the proportion of aluminum in the product so minute, that it will not make a difference to my health? Thanks.

- It's actually Sodium Aluminum Phosphate. It's used as a preservative in a lot of food actually. It's not exactly good for you, but it's really no more harmful than any other preservative. So basically, it's unhealthy, but you're not gonna die from eating them. EDIT: Yes I realize that Aluminum has been linked to Alzheimer's disease, but this isn't Aluminum. Aluminum is an element. This is Sodium Aluminum Phosphate. A completely different substance. When an element bonds with another element (or two) often its properties completely change. I think you'd be surprised to learn that Sodium by itself, is not only horribly volatile (it will explode in water) and will kill you if you ingested it. Iodine is also poisonous in fairly moderate doses. But when the two are bonded together (sodium iodide) it becomes an essential nutrient to the body.

Send your message to us

Aluminum Sheets in North Dakota - Aluminum Bar Flat Welding with Aluminum Rod Bar for Aluminum Grating

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords