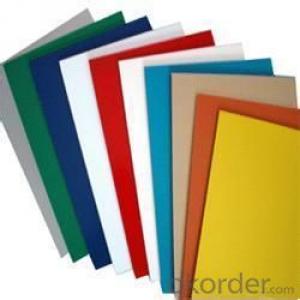

Pre Painted Aluminum Foil - Aluminum Sheets North Dakota

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is aluminium bronze (Cu-Al alloy).

- Q: Can aluminum sheets be used for heat dissipation?

- Yes, aluminum sheets can be used for heat dissipation. Aluminum is known for its excellent thermal conductivity, which allows it to efficiently transfer heat away from a source. This makes it a popular choice for heat sinks and heat exchangers in various industries. Aluminum sheets can be shaped and formed into different configurations to maximize surface area and enhance heat dissipation. The lightweight and corrosion-resistant nature of aluminum also make it a preferred material for heat dissipation applications.

- Q: Are aluminum sheets suitable for decorative lighting fixtures?

- Yes, aluminum sheets are highly suitable for decorative lighting fixtures. Aluminum is a lightweight and versatile material that is easy to work with and manipulate into various shapes and designs. It offers excellent corrosion resistance, making it suitable for both indoor and outdoor lighting fixtures. Additionally, aluminum can be easily coated or painted to achieve different finishes, allowing for endless design possibilities. Its reflective properties also contribute to enhancing the overall lighting effect, making it an ideal choice for decorative lighting fixtures.

- Q: What safety measures should be taken into account when installing aluminum sheets?

- <p>When installing aluminum sheets, it's important to follow safety precautions. Always wear appropriate personal protective equipment, including gloves and safety glasses. Ensure the work area is clear of debris and other hazards. Use the correct tools for cutting and handling aluminum sheets to prevent injuries. Be cautious of sharp edges and corners that can cause cuts. Ensure the aluminum sheets are properly secured to avoid them falling and causing harm. Follow all manufacturer guidelines for installation to ensure the stability and longevity of the aluminum sheets.</p>

- Q: How do aluminum plates drill?

- Can also be a self tapping screw drill, which can drill.

- Q: What type of aluminum plate does it contain?

- The 3 * * * series aluminum plate is mainly composed of manganese, and the content is between 1.0-1.5%.4 * * * series aluminum sheet: stands for 4A01. The 4 * * * series aluminum plate belongs to a series with high silicon content.5 * * * series aluminum sheet: stands for 5052, 5005, 5083, 5A05 series.

- Q: What safety measures should be considered when handling large quantities of aluminum sheets?

- <p>When working with large amounts of aluminum sheets, it's important to take several precautions. Always wear protective gloves and eyewear to prevent cuts and eye injuries. Ensure good ventilation to avoid inhaling aluminum dust, which can be harmful. Use proper lifting techniques to avoid back injuries, and never exceed the weight limits of any equipment. Store aluminum sheets in a dry, cool place to prevent corrosion. Be cautious of static electricity buildup, which can be a fire hazard, especially in dry conditions. Finally, be aware of the risk of aluminum dust igniting, so avoid open flames and sparks near stored or processed aluminum sheets.</p>

- Q: Can 101 aluminum sheets be used in the production of sporting goods?

- Yes, 101 aluminum sheets can be used in the production of sporting goods. Aluminum is a lightweight and durable material that is commonly used in the manufacturing of various sporting equipment such as baseball bats, tennis rackets, and bicycle frames.

- Q: which is the best bonding method for aluminum sheet and plastic?

- smear glue, there is a glue special for the bonding of plastic and steel materials.

- Q: What does aluminum plate "H12" mean?

- The utility model is suitable for the products with stable mechanical performance after work hardening, heat treatment or heat treatment in the process of processing. The H3 state is only applicable to the alloy gradually softening at room temperature (unless stabilized). H4 - the state of work hardening and coating treatment. The utility model is suitable for products with incomplete annealing after work hardening and after coating treatment.The second digits behind the H indicate the degree of work hardening of the product. The number 8 indicates a hard state. The minimum tensile strength of a hx8 is specified by the sum of the minimum tensile strength of the o state and the specified strength difference. For the states between O (annealed) and hx8 States, the numbers from 1 to 7 should be added after the HX code, adding the number 9 to the HX to indicate a more severe state of hardening than the hx8.

- Q: Can aluminum sheets be used for heat exchangers?

- Indeed, heat exchangers can utilize aluminum sheets. Aluminum, known for its remarkable heat conductivity, proves to be a perfect choice when it comes to heat exchangers. Its superior thermal conductivity facilitates exceptional heat transfer between fluids, leading to efficient heat exchange. Moreover, aluminum sheets possess the advantages of being lightweight, resistant to corrosion, and exhibiting commendable mechanical properties. These additional attributes further enhance their suitability for various heat exchanger applications.

Send your message to us

Pre Painted Aluminum Foil - Aluminum Sheets North Dakota

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords