Raw Aluminum Sheets - Aluminium Ceiling Panels for Sale in China Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

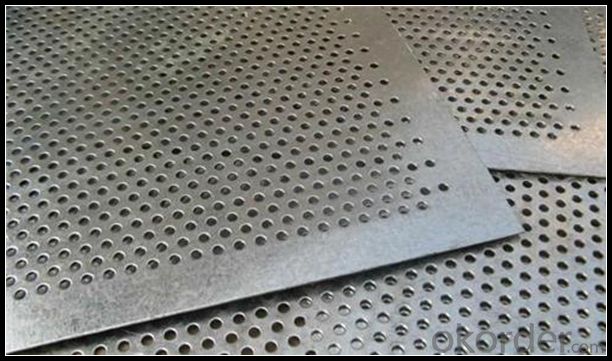

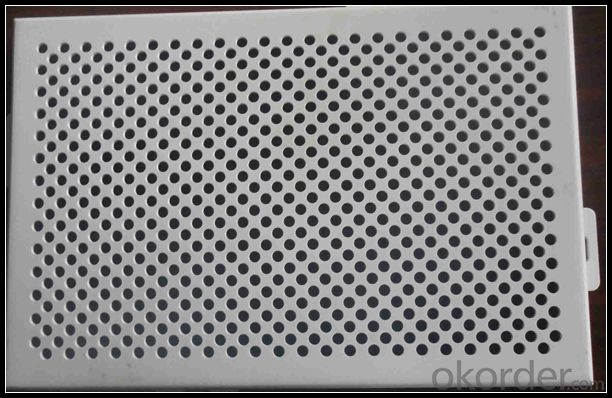

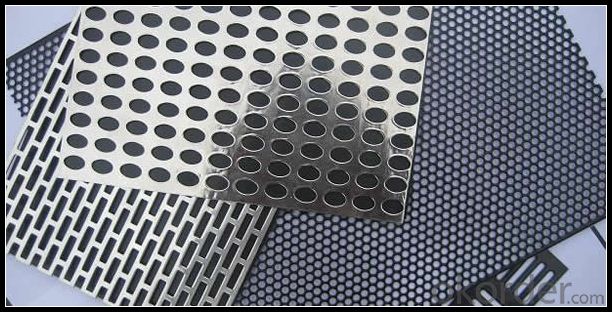

1.Structure of Aluminium Ceiling Panels for Sale in China Supplier

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminium Ceiling Panels for Sale in China Supplier

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

3. Aluminium Ceiling Panels for Sale in China Supplier Images

4.Specification of Aluminium Ceiling Panels for Sale in China Supplier

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Can aluminum sheets be used for packaging purposes?

- Aluminum sheets have the ability to serve as packaging material. Due to its exceptional barrier properties, durability, and lightweight nature, aluminum is a versatile and favored choice for packaging. It is commonly employed in various forms, such as aluminum foil, cans, and containers, to pack a diverse range of products like food, beverages, pharmaceuticals, and cosmetics. The utilization of aluminum sheets for packaging offers numerous advantages. These sheets possess resistance against moisture, oxygen, light, and bacteria, which ensures the protection and preservation of the packaged contents. Furthermore, aluminum sheets can be easily manipulated, shaped, or folded to create a variety of packaging designs, making it a preferred option for numerous packaging applications.

- Q: This question asks for methods to guarantee the safety and reliability of a project when using aluminum sheets.

- <p>To ensure your project's safety and reliability using aluminum sheets, follow these steps: 1. Choose high-quality aluminum sheets with the appropriate thickness and grade for your project's requirements. 2. Ensure proper design and engineering to withstand expected loads and stresses. 3. Use appropriate fasteners and joinery methods to secure the sheets, avoiding stress concentrations. 4. Implement corrosion protection measures such as coatings or anodizing, especially for outdoor applications. 5. Perform regular inspections and maintenance to check for signs of wear, corrosion, or damage. 6. Adhere to safety standards and regulations for aluminum construction. 7. Consult with professionals or engineers experienced in aluminum fabrication for guidance and validation.</p>

- Q: What is an aluminum sheet?

- An aluminum sheet refers to a flat, thin piece of aluminum that is usually rectangular in shape. It is commonly used in various industries and applications due to its lightweight, durability, and corrosion resistance properties. Aluminum sheets can be easily manipulated, cut, and formed into different shapes to meet specific requirements in construction, automotive, aerospace, and manufacturing sectors.

- Q: Can the aluminum sheets be bent or formed into different shapes?

- Yes, aluminum sheets can be easily bent or formed into different shapes due to their malleability and ductility.

- Q: What are the different methods of heat treating aluminum sheet?

- Aluminum sheet can undergo various heat treatment methods, each serving a specific purpose and achieving desired outcomes. Some commonly used methods include the following: 1. Solution Heat Treatment: The aluminum sheet is heated to a specific temperature, typically ranging from 900-1000°F (480-540°C), and kept at that temperature for a designated duration. This process aids in dissolving any soluble alloying elements present in the aluminum, resulting in a more uniform structure. 2. Quenching: Following the solution heat treatment, the aluminum sheet is rapidly cooled by immersing it in water, oil, or air. This rapid cooling helps retain the desired microstructure and properties, such as increased strength and hardness. 3. Aging: After quenching, the aluminum sheet undergoes an aging process. It is heated to a lower temperature, typically between 250-450°F (120-230°C), and maintained at that temperature for a specific period. This allows for the precipitation of fine particles within the aluminum, further enhancing its strength and hardness. 4. Precipitation Hardening: This method is specifically employed for certain aluminum alloys, such as the 2000 and 7000 series, which respond well to precipitation hardening. It involves a combination of solution heat treatment, quenching, and aging, resulting in a highly strengthened and durable aluminum sheet. 5. Annealing: Annealing is a heat treatment process that aims to soften the aluminum sheet and relieve any internal stresses. The sheet is heated to a specific temperature, typically around 600-700°F (315-370°C), and then slowly cooled. This enhances the formability and machinability of the aluminum. 6. Stress Relieving: Similar to annealing, stress relieving is specifically used to reduce residual stresses in the aluminum sheet after fabrication. The sheet is heated to a temperature below its annealing temperature and then slowly cooled. The choice of heat treatment method for aluminum sheet depends on the desired properties, alloy composition, and intended application. Each method offers unique advantages and can significantly enhance the mechanical and physical properties of the aluminum sheet.

- Q: Can aluminum sheets be used for reflective surfaces?

- Yes, aluminum sheets can be used for reflective surfaces. Aluminum is known for its high reflectivity, making it an excellent material for creating reflective surfaces. Due to its smooth and highly polished finish, aluminum sheets can effectively reflect light, heat, and other forms of radiation. This property makes them suitable for a wide range of applications, including solar panels, mirrors, lamp reflectors, and reflective insulation. The use of aluminum sheets as reflective surfaces is advantageous due to their durability, lightweight nature, and resistance to corrosion.

- Q: Can aluminum sheets be laser cut?

- Yes, aluminum sheets can be laser cut. Laser cutting is a popular method for cutting aluminum sheets due to its precision and efficiency. The laser cutting process involves using a high-powered laser to melt or vaporize the material, creating a clean and accurate cut. Aluminum is a highly reflective material, so it requires a higher-powered laser to effectively cut through it. However, once the correct laser settings are determined, aluminum sheets can be easily and precisely cut using a laser cutting machine. This method is widely used in industries such as automotive, aerospace, and manufacturing for various applications involving aluminum sheets.

- Q: Can aluminum sheets be hydroformed?

- Yes, aluminum sheets can be hydroformed.

- Q: What are the different alloys used in aluminum sheets?

- Aluminum sheets utilize a variety of alloys, each possessing its own distinct properties and characteristics. Some commonly employed alloys include: 1. Alloy 1100: Renowned for its exceptional corrosion resistance and superior electrical conductivity, this alloy finds extensive utilization in applications necessitating high formability and weldability. Examples include food packaging and electrical conductors. 2. Alloy 3003: Esteemed for its formidable formability, moderate strength, and outstanding corrosion resistance, this alloy enjoys widespread application in cooking utensils, chemical equipment, and general sheet metal work. 3. Alloy 5052: Recognized for its robust strength and commendable corrosion resistance, this alloy frequently finds application in marine settings, as well as aircraft fuel tanks and automotive components. 4. Alloy 6061: One of the most versatile and frequently employed aluminum alloys, this variant boasts excellent corrosion resistance, satisfactory weldability, and moderate strength. It is commonly utilized in structural components like frames and railings, as well as automotive and aerospace applications. 5. Alloy 7075: Distinguished by its impressive strength-to-weight ratio and exceptional fatigue resistance, this alloy is often chosen for applications necessitating formidable strength, such as aircraft and aerospace components, as well as high-performance sporting goods. These examples merely scratch the surface of the numerous alloys employed in aluminum sheets. The selection of a particular alloy hinges on the specific requirements of the application, encompassing factors such as strength, corrosion resistance, formability, and weldability.

- Q: Are aluminum sheets suitable for food contact applications?

- Yes, aluminum sheets are suitable for food contact applications. Aluminum is a non-toxic and non-reactive metal that does not leach harmful substances into food. It is widely used in the food industry for packaging, cooking utensils, and food storage containers. Additionally, aluminum exhibits excellent heat conductivity and can be easily cleaned, making it a popular choice for food-related applications.

Send your message to us

Raw Aluminum Sheets - Aluminium Ceiling Panels for Sale in China Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords