Aluminum Alloy Sheets for Spaceflight - Aluminium Back Coils for Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

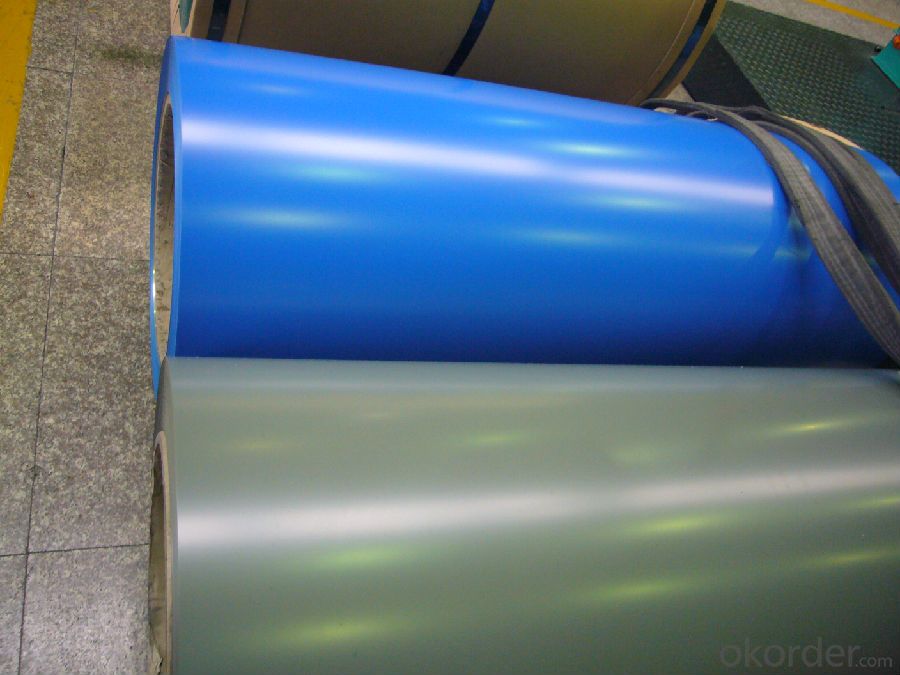

1.Structure of Aluminium Back Coils for Aluminium Composite Panel

Aluminium Back Coils for Aluminium Composite Panel are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of Aluminium Back Coils for Aluminium Composite Panel

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Coating | Coating Thickness | Weight |

| AA1050 | H14 | Polyester | 20-25microns | about 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: I want to use one aluminum bottle, rather than several plastic ones. And this may sound stupid, but will an aluminum water bottle be safe to put in the fridge?

- yea it would be safe because my brother does it all the time. Also you can just refill your plastic bottles with water and put in the fridge and the freezer because I do that all the time and i'm still using the same water bottles and they are in great shape and the fridge and freezer keep my water nice in cold.

- Q: how to process 0.3mm hole on aluminum material?

- punching wire-electrode cutting

- Q: Are 101 aluminum sheets suitable for chemical processing equipment?

- 101 aluminum sheets are not suitable for chemical processing equipment. While aluminum is a versatile and widely used material, it is not recommended for applications involving strong acids or bases. Aluminum is susceptible to corrosion when exposed to certain chemicals, and this can compromise the integrity of the equipment and potentially lead to leaks or other safety hazards. For chemical processing equipment, it is advisable to choose materials that are specifically designed and manufactured to withstand the corrosive effects of the chemicals being used.

- Q: i m not sure if aluminum hydroxide is a acid or base. if somebody could help me, i will really appreciate.If u can could you also tell me if im wrong or right about the following substances:- pepsi cola is acid- vinegar is a base- ammonia is a base- aluminum hydroxyde is ?thank u for your help.

- Aluminium is amphoteric, which means it can act as an acid or base depending on reaction conditions acid conditions it acts as a base Al(OH)3 s + 3HCl aq == AlCl3 aq + 3H2O Alkaline conditions Al(OH)3 s + OH- aq === Al(OH)4 - aq the aluminate ion in case of NaOH aq sodium aluminate is formed Pepsi acidic vinegar acidic ammonia base AlOH3 amphoteric as described

- Q: Can aluminum sheets be easily bent or shaped?

- Yes, aluminum sheets can be easily bent or shaped due to their malleability, making them ideal for various applications in industries such as construction, automotive, and aerospace.

- Q: I may use the copper or brass for an inlay on a decorative piece of aluminum I'm working on.....

- aluminum okorder / so what you are finding is that aluminum will melt before the copper or brass...

- Q: I have a problem when machining aluminium in my machine shop. There are times when the machines aluminium surface turns yellowish (somtimes brown). I do not know what is the main cause of the problem. Is it due to the coolant used?

- Aluminum oxides may appear in different colors depending on hydration states and other variables. Look in a CRC Handbook of Chemistry Physics if available for aluminum compounds and their colors. The colors that you see may also have as much to do with the surface finish as the color of the material on the surface. A microscopically rough surface will appear dark next to a polished surface due to light scattering. I will agree with Ling in principle, but not on details. EDS detection limits on homogeneous samples can be better than 0.1%, although not so good for elements at the light end of the detection range. Current detectors can detect chlorine (a common culprit for aluminum discoloration) at about 0.1%. Your problem with detection and one that Ling has addressed previously may be that a thin film of contamination would not be easily detected by EDS. As Ling suggests, SIMS is a good technique for detecting thin films and low concentrations. The problem with SIMS in this case may be that the detection limits are too good and the technique cannot be quantified. SIMS would detect 2 ppm of chloride and you couldn't tell for sure whether it was 2 ppm, which is probably not an issue here, or 2000 ppm, which would be significant. I would suggest x-ray photoelectron spectroscopy (ESCA or XPS) as an alternative for further study. The technique will analyze thin films (20 A) and detection limits are good enough (about 0.1%). In addition, XPS will give you information about the compounds present, e.g. whether the oxygen is aluminum oxide, aluminum hydroxide, etc. Good Luck.

- Q: how to distinguish the physical property of copper sheet from the one of aluminum sheet?

- physical property: copper sheet: golden, heavy, aluminum sheet: white, light.

- Q: Can 101 aluminum sheets be used in electrical or electronic components?

- Yes, 101 aluminum sheets can be used in electrical or electronic components.

- Q: Can aluminum sheet be used for electrical grounding applications?

- Indeed, aluminum sheet finds utility in electrical grounding applications. It possesses remarkable conductive properties, rendering it apt for employment in grounding systems. Its low resistance and exceptional electrical conductivity make it a common choice in diverse electrical applications. With the capability to proficiently transport electrical current and securely disperse it into the ground, aluminum sheet guarantees the safeguarding of electrical systems and averts potential electrical dangers. Moreover, the lightweight and corrosion-resistant attributes of aluminum establish it as a favored option for grounding applications across numerous industries, encompassing construction, automotive, and aerospace.

Send your message to us

Aluminum Alloy Sheets for Spaceflight - Aluminium Back Coils for Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords