Aluminum Coil for Sandwich Panel Material - Aluminum Sheets for Boats

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 360 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

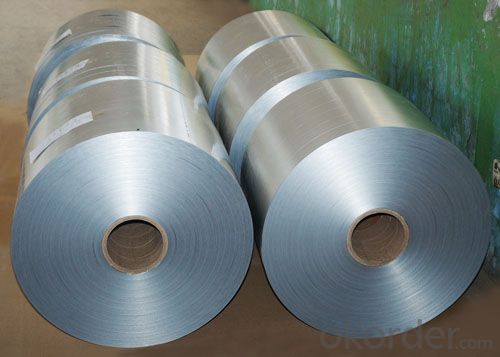

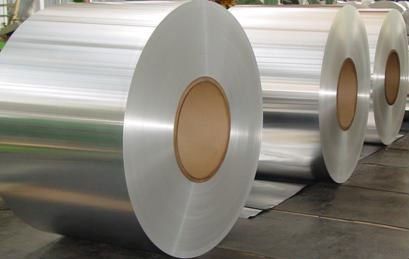

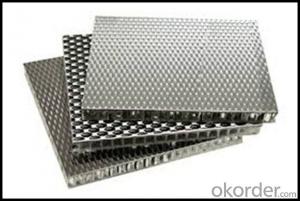

Aluminum Coil for Sandwich Panel Material

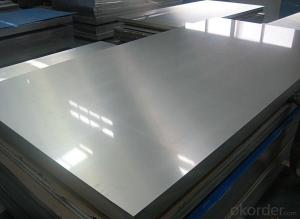

Hot-rolled High Quality Low Price Aluminum Coil is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

Temper: O, F, HXX

Thickness: Thickness

Width: 1000-1500mm

Type: Coil/Roll

Surface Treatment: mill finished

Application: Decoration, packaging, printing, covering

Standard size: Upon customer's demand

Quantity: 18tons(±10%)in one 20 feet container

Hot Rolled Aluminium coil | ||||||||||||||||

Aluminium Coils, non-alloy and alloy products have many different applications, they are used windly throughout construction, building, decoration, lighting, metal nameplate, aircraft and aerospace structures, etc. | ||||||||||||||||

Specification | ||||||||||||||||

ALLOY | TEMPER | THICKNESS | WIDTH(mm) | LENGTH(mm) | ||||||||||||

1050,1060,1070, | O,F, H12, 114,H18,H22, H24,H26,H32, H34,H36,H111, | 3.0-10.0 | 1000--1500mm | in Coil | ||||||||||||

chemical composition | ||||||||||||||||

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ca | V | Ti | Other | Min.Al | |||

1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.50 | |||

1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.60 | |||

1070 | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | - | - | 0.04 | - | 0.05 | 0.03 | 0.03 | 99.70 | |||

1100 | 0.95 | 0.05-0.2 | 0.05 | - | - | - | 0.10 | - | - | - | 0.05 | 99.00 | ||||

3003 | 0.60 | 0.70 | 0.5-0.2 | 1.0-1.5 | - | - | - | 0.10 | - | - | - | 0.15 | 96.95-96.75 | |||

3004 | 0.30 | 0.70 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | - | 0.25 | - | - | - | 0.15 | 96.55-95.55 | |||

Packaging detail: First, plastic cloth; Second, Pearl Wool ; Third, wooden cases with dry agent ,without fumigation, wooden pallets

Delivery detail: Within 25days

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

- Q: What specific treatments or coatings are required for exterior applications to ensure durability and protection?

- <p>Yes, for exterior applications, special coatings or finishes are often necessary to protect against weathering, UV radiation, and other environmental factors. These may include weather-resistant paints, UV-resistant coatings, and corrosion-resistant finishes. For example, in construction, exterior walls might be treated with a water-repellent coating to prevent water damage, while metal structures may require anti-corrosion coatings to withstand harsh weather conditions. The choice of coating depends on the material, climate, and specific requirements of the application.</p>

- Q: What is the maximum temperature resistance of aluminum sheets?

- The maximum temperature resistance of aluminum sheets is typically around 600 degrees Fahrenheit (315 degrees Celsius). However, this can vary depending on various factors such as the alloy composition, thickness, and treatment of the aluminum sheets. It is always important to consult the manufacturer's specifications or obtain professional advice when considering the use of aluminum sheets in high-temperature applications.

- Q: What are the dimensions and thickness options for aluminum sheets?

- Depending on specific requirements and applications, the dimensions and thickness options for aluminum sheets can vary. There is a wide range of sizes and thicknesses available to cater to different needs. Concerning dimensions, aluminum sheets come in various widths and lengths, typically ranging from 36 inches to 72 inches in width and 96 inches to 144 inches in length. However, these dimensions may vary depending on the supplier and the specific product. The thickness options for aluminum sheets also differ. Thickness is usually measured in gauge, where lower gauge numbers indicate thicker sheets. Aluminum sheets can be obtained in various gauges, ranging from 0.006 inches (very thin) to 0.5 inches (thicker) or even thicker for specialized applications. It is important to note that the specific dimensions and thickness options may vary depending on the supplier and the grade of aluminum being used. It is always advisable to consult with a supplier or manufacturer to obtain precise information about the available dimensions and thickness options for aluminum sheets.

- Q: is aluminum foil spacer poisonous after heating?

- many baked food will use aluminum foil.

- Q: Are aluminum sheets suitable for electrical transformers?

- Indeed, electrical transformers can certainly make use of aluminum sheets. Aluminum, being a highly conductive material, presents numerous benefits when employed in transformers. Primarily, its electrical resistance is lower in comparison to other materials such as copper, enabling efficient transmission of electrical energy. Consequently, this leads to reduced energy losses and enhanced overall performance. Furthermore, aluminum possesses the advantage of being lightweight, rendering it easier to handle and install. Moreover, it is also more economical than copper, thus making it the preferred option for extensive transformer applications. All in all, aluminum sheets offer a dependable and effective resolution for electrical transformers.

- Q: i know what aluminum is but oxide is not found on the periodic table, and the teacher also gave us a list of common oxidation numbers for polyatomic ions and it is not there also, can anyone help me?

- Aluminum Oxide is just the name of an ionic compound. Kind of like Sodium Chloride. While there is no chloride atom, we know it's just that's the traditional way to name NaCl (table salt.) Aluminum Oxide just means it is aluminum and oxygen combined to form a charge neutral ionic compound. Since we know aluminum has a charge of 3+ (this can be obtained from the periodic table or a chart of cations) and Oxygen has a charge of 2- ( we can obtain this from the periodic table or a chart of anions), all we have to do is make a charge neutral species. In this case Al_2O_3 (those are subscripts) is the correct species because it is neutral. So now we just calculate the weight. Al = 26.98 O= 15.99 so we have 2 Al and 3 O 2 * (26.98) + 3 * (15.99) = 101.9 grams/mol

- Q: Can aluminum sheet be used for packaging applications?

- Yes, aluminum sheet can definitely be used for packaging applications. Aluminum is widely used in the packaging industry due to its excellent properties. It is lightweight, strong, durable, and malleable, making it ideal for packaging various products. Aluminum sheets can be easily formed into different shapes and sizes, allowing for custom packaging solutions. Additionally, aluminum has excellent barrier properties, providing protection against moisture, gases, and light, which helps to maintain the freshness and quality of the packaged goods. Furthermore, aluminum is non-toxic and can be easily recycled, making it a sustainable choice for packaging applications. Overall, aluminum sheet is a versatile and reliable material for packaging various items, including food, beverages, pharmaceuticals, cosmetics, and many others.

- Q: Are aluminum sheets suitable for lightweight structures?

- Indeed, aluminum sheets prove to be a fitting choice when it comes to lightweight structures. Renowned for its low density and impressive strength-to-weight ratio, aluminum emerges as an optimal material for applications requiring reduced weight. Industries such as aerospace, automotive, and construction frequently rely on aluminum sheets due to their exceptional corrosion resistance, durability, and malleability. These properties facilitate effortless fabrication and installation. Moreover, the versatility of aluminum sheets extends to their effortless joining through diverse welding and adhesive methods, thereby bolstering their aptness for lightweight structures.

- Q: Can the aluminum sheets be used for manufacturing aircraft parts?

- Aluminum sheets are indeed suitable for the production of aircraft parts. They are a lightweight and durable material commonly utilized in the aerospace sector. With its exceptional strength-to-weight ratio, corrosion resistance, and excellent formability, aluminum is ideal for various applications in aviation. It is effortless to fabricate aluminum sheets into intricate shapes, making them perfect for manufacturing aircraft wings, fuselages, panels, and structural supports. Moreover, aluminum's high conductivity facilitates efficient heat dissipation in crucial areas of the aircraft. Consequently, aluminum sheets are widely preferred for aircraft part manufacturing due to their desirable properties and reliability in the aerospace field.

- Q: What is the corrosion resistance of aluminum sheets?

- Aluminum sheets have excellent corrosion resistance. Aluminum naturally forms a protective oxide layer on its surface when exposed to oxygen, which acts as a barrier against corrosion. This oxide layer is very stable and prevents further oxidation of the metal, making aluminum highly resistant to corrosion in most environments. Additionally, aluminum sheets can be further enhanced with surface treatments or coatings to increase their corrosion resistance even more. This makes aluminum sheets a popular choice for various applications where corrosion resistance is crucial, such as in the construction industry, automotive manufacturing, and marine applications.

Send your message to us

Aluminum Coil for Sandwich Panel Material - Aluminum Sheets for Boats

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 360 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords