Aluminum Foil Sheets for Sale - Prepainted Aluminum Coil for Composite Panel Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Prepainted Coil for Composite Pannel Making Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Prepainted Coil for Composite Pannel Making:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

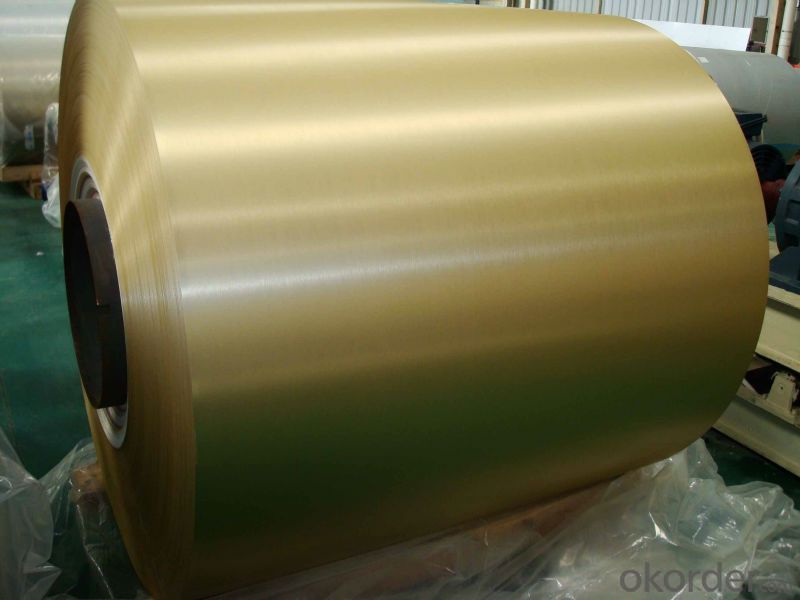

Images of the Aluminium Prepainted Coil for Composite Pannel Making:

Aluminium Composite Pannel for Curtain Wall Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Prepaited Coil:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What is the cost of aluminum sheets compared to other metals?

- The cost of aluminum sheets is generally lower compared to other metals such as stainless steel or copper. Aluminum is a widely available and abundant material, which contributes to its relatively affordable price in comparison to other metals.

- Q: Aluminum is put into copper chloride and how can you tell what happens to them visually?

- Aluminum will reduce copper ions (and be oxidized) when chloride ions are present. Otherwise aluminum metal will pretty much just sit there. The reason is the passivating layer of Al2O3 on the surface of any piece of aluminum. This metal oxide layer prevents the metal from actually reacting. But in the presence of chloride ion in water, Al2O3 will react, resulting in AlCl4^- and OH- ions. Al2O3(s) + 8Cl- + 3H2O(l) -- 2AlCl4^- + 6OH- This allows the aluminum metal to come into contact with copper ions resulting in the redox reaction: 2Al(s) + 3Cu2+ -- 2Al^3+ + 3Cu(s) There is a side reaction where aluminum metal reacts with water, and hydrogen gas is produced. 2Al(s) + 2H2O --2 AlOH^2+ + H2(g) When you actually observe the reaction, you will see copper metal being formed, aluminum metal dissolve and bubbles of hydrogen gas being given off. ============ Follow up ============= Because of the passivating effect of Al2O3 and the fact that Al2O3 dissolves in the presence of Cl- forming a new complex ion, AlCl4^-, Brian's answer leaves out a lot of the important chemistry.

- Q: What are the primary components that make up aluminum sheets?

- <p>Aluminum sheets are primarily composed of aluminum, which is a lightweight and malleable metal. They are made from pure aluminum or aluminum alloys, which may include small percentages of other elements to enhance specific properties such as strength, corrosion resistance, or workability. Common alloying elements include copper, magnesium, manganese, silicon, and zinc. The exact composition varies depending on the specific grade of aluminum and its intended use. Pure aluminum is soft and not commonly used for sheets; instead, alloys are preferred for their improved strength and durability.</p>

- Q: Can aluminum sheets be used for chemical storage containers?

- Yes, aluminum sheets can be used for chemical storage containers. Aluminum is a corrosion-resistant metal that can withstand the chemical reactions of various substances, making it suitable for storing a wide range of chemicals. Additionally, aluminum is lightweight, durable, and easily formable, making it a practical choice for manufacturing chemical storage containers.

- Q: Are 101 aluminum sheets readily available in the market?

- Yes, 101 aluminum sheets are readily available in the market.

- Q: How many atoms are in a 2.80 cm* 2.80cm*2.80cm cube of aluminum?

- 2.8cm * 2.8cm * 2.8cm= 21.95 cm^3 is volume of Aluminum present Density of Al = 2.7g/cm^3 Convert volume of aluminum into grams of Aluminum, make sure your units cancel 21.95 cm^3 * (2.7g/1 cm^3) = 59.26 g Al Next, find how many moles of Al you have. MW Al = 27g/mol 59.26/27 = 2.19 moles Al Use Avogadro's number to find number of atoms of Al - 2.19 moles Al * (6.022x10^23 atoms/1 mol Al) = 1.32x10^24 atoms Al

- Q: What is the typical sheet size tolerance for aluminum sheets?

- The specific application and industry standards can cause variations in the typical sheet size tolerance for aluminum sheets. Generally, the industry standard for aluminum sheet size tolerance is approximately +/- 0.005 inches. This indicates that the actual size of the aluminum sheet can differ up to 0.005 inches from the specified or desired size. It is worth noting that this tolerance can be adjusted based on the project requirements or customer preferences. Moreover, it is recommended to seek guidance from the manufacturer or supplier of the aluminum sheets for accurate and current information on sheet size tolerances, as they may have their own guidelines or capabilities that differ from the industry standard.

- Q: Do the aluminum sheets come with a protective coating?

- Indeed, the aluminum sheets are accompanied by a protective coating, which is skillfully applied in order to safeguard against any potential scratches, corrosion, or other forms of damage that may occur during the process of transportation and handling. This meticulous coating process guarantees that the aluminum sheets are delivered to our cherished customers in an immaculate state.

- Q: 10mm how much is the aluminum sheet?

- The price is calculated according to the price of aluminum ingot + processing fees (aluminum state), the specific price according to the size of the aluminum plate, zero shear and the whole board price also has the difference, Jiangsu Yi Heng Liaoning Wang Zhong Nanshan aluminum do this thickness.

- Q: Can aluminum sheets be used for decorative ceilings?

- Indeed, decorative ceilings can utilize aluminum sheets. The versatility of aluminum allows for the creation of a multitude of designs and patterns, resulting in visually pleasing ceilings. Its lightweight nature, durability, and resistance to corrosion make it a favored choice for decorative purposes. Furthermore, aluminum sheets can be powder-coated or painted in various colors, enabling them to align with the desired aesthetic of any given space. Regardless of whether the purpose is residential or commercial, aluminum sheets provide a contemporary and fashionable option for crafting decorative ceilings.

Send your message to us

Aluminum Foil Sheets for Sale - Prepainted Aluminum Coil for Composite Panel Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords