Aluminum Composite Sheets for Open Air Outer Decoration Aluminium Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

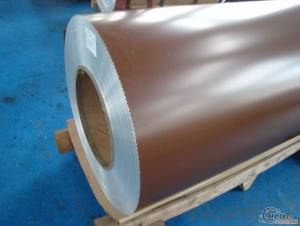

1.Structure of Aluminium Coils for Open Air Outer Decoration

Aluminium Coils for Open Air Outer Decoration is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminium Coils for Open Air Outer Decoration

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| ALLOY | TEMPER | WIDTH | COATING | THICKNESS |

| AA1050 | H14 | 1000MM-1500MM | POLYESTER | 0.2MM-3MM |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are aluminum sheets suitable for use in food processing or packaging industries?

- Yes, aluminum sheets are suitable for use in food processing or packaging industries. Aluminum is a widely used material in the food industry due to its excellent properties such as being lightweight, corrosion-resistant, and having good thermal conductivity. It is also impermeable to moisture, oxygen, and light, which helps to preserve the quality and freshness of food products. Additionally, aluminum sheets can be easily formed into various shapes and sizes, making them versatile for different packaging requirements.

- Q: Is aluminum sheet resistant to UV rays?

- Indeed, aluminum sheet exhibits resistance to UV rays. By nature, aluminum develops a safeguarding oxide layer which functions as a shield against UV radiation. This protective layer aids in safeguarding the aluminum sheet from harm or deterioration caused by the sun's UV rays. Consequently, aluminum sheet proves to be an appropriate material for outdoor usage, enduring extended exposure to sunlight without experiencing fading or deterioration. Moreover, the reflective characteristics of aluminum also contribute to its resistance against UV rays, as it can effectively reflect a considerable portion of the sun's rays, diminishing heat absorption and the likelihood of damage.

- Q: This question asks about the expected duration or service life of aluminum siding or cladding used in construction.

- <p>The lifespan of aluminum siding or cladding typically ranges from 20 to 50 years, depending on the quality of the material, installation, and environmental conditions. High-quality aluminum siding, when properly maintained and installed, can last up to 50 years. It is resistant to rust and decay, making it a durable choice for exterior cladding. However, factors such as extreme weather conditions, poor installation, and lack of maintenance can reduce its lifespan.</p>

- Q: What are the different methods of surface treatment for adhesive bonding of aluminum sheet?

- Aluminum sheet adhesive bonding can be enhanced through various surface treatment methods. These methods aim to improve the strength and durability of the adhesive joint. Some commonly employed techniques include: 1. Enhancing mechanical interlock: One approach involves roughening the aluminum surface using sandblasting, abrasion, or wire brushing. This creates a stronger mechanical interlock between the adhesive and the aluminum, ultimately increasing bond strength. 2. Chemical treatment for surface improvement: Chemical treatments can eliminate contaminants, oxidation, or corrosion from the aluminum surface. Acid etching, chromate conversion coating, or anodizing are commonly used methods. These treatments enhance surface cleanliness and promote adhesion by creating a chemically reactive surface for the adhesive. 3. Plasma treatment: Exposing the aluminum surface to a low-temperature plasma discharge modifies the surface energy and eliminates contaminants. This treatment enhances the adhesive's wettability and adhesion. 4. Primer coating: Applying a primer coat on the aluminum surface facilitates chemical bonding between the adhesive and the substrate. Primers are designed specifically to enhance adhesion to certain substrates, thereby improving bond strength and durability. 5. Surface activation: Techniques like flame treatment or corona treatment can increase the surface energy of the aluminum sheet. These methods generate free radicals on the surface, thereby improving the adhesive's bonding characteristics. It's worth noting that the choice of surface treatment method depends on factors such as the specific adhesive used, desired bond strength, application requirements, and the condition of the aluminum surface. It is advisable to consult adhesive manufacturers or experts to determine the most suitable surface treatment method for a particular adhesive bonding application.

- Q: What is the corrosion resistance of 101 aluminum sheets in saltwater environments?

- The corrosion resistance of 101 aluminum sheets in saltwater environments is generally considered to be quite good. Aluminum is inherently resistant to corrosion, and when exposed to saltwater, it forms a protective oxide layer on its surface that further enhances its resistance to corrosion. This oxide layer acts as a barrier, preventing the saltwater from coming into direct contact with the underlying metal and thus slowing down the corrosion process. However, it is important to note that prolonged exposure to saltwater can still lead to some degree of corrosion over time. Regular maintenance and protective coatings can help to further enhance the corrosion resistance of 101 aluminum sheets in saltwater environments.

- Q: What are the various kinds of aluminum sheets utilized in the manufacturing of automobiles?

- <p>Aluminum sheets are widely used in automobile manufacturing due to their lightweight and strength. The different types include: 1. 5000 series aluminum sheets, known for their good formability and corrosion resistance, often used for body panels. 2. 6000 series aluminum sheets, which are strong and used for structural components. 3. 7000 series aluminum sheets, known for their high strength-to-weight ratio, used in safety-critical parts. 4. Aluminum alloy sheets, which combine the properties of aluminum with other elements for specific applications. 5. Aluminum clad sheets, which have a corrosion-resistant layer on the surface. These types are chosen based on the specific requirements of each automotive component.</p>

- Q: Is it possible to use aluminum sheets for indoor purposes?

- <p>Yes, aluminum sheets can be used for indoor applications. They are commonly used in interior design for their durability, lightweight, and resistance to corrosion. Aluminum sheets are often utilized in the construction of furniture, decorative panels, and even as a material for interior walls and ceilings. Their ease of maintenance and ability to be recycled make them an environmentally friendly option for indoor use.</p>

- Q: Are 101 aluminum sheets resistant to UV radiation?

- Generally speaking, 101 aluminum sheets exhibit resistance to UV radiation. This is due to the formation of a natural thin oxide layer on the surface of aluminum, which serves as a protective shield against UV rays. Consequently, the aluminum is safeguarded from deterioration or degradation when exposed to sunlight. Nevertheless, it is worth noting that prolonged exposure to intense UV radiation can still result in gradual discoloration or fading. Therefore, in situations where the aluminum sheets will be continuously exposed to direct sunlight for long durations, it is recommended to consider applying a protective coating or utilizing a specialized UV-resistant paint. These measures will further enhance the aluminum sheets' ability to withstand UV radiation.

- Q: This question asks for a comparison of the positive and negative aspects of utilizing aluminum sheets in building construction.

- <p>Aluminum sheets in construction offer several advantages, including lightweight properties that reduce structural load, excellent corrosion resistance, and durability which minimizes maintenance needs. They are also energy-efficient, reflecting heat and reducing cooling costs. Additionally, aluminum is recyclable, contributing to sustainability. Disadvantages include higher initial costs compared to some traditional materials and potential for dents or damage from impacts. Aluminum can also be noisy when walked on, and it may require additional insulation for thermal performance, adding to the overall cost.</p>

- Q: Are aluminum sheets suitable for marine vessel construction?

- Indeed, marine vessel construction can make use of aluminum sheets. Aluminum, a material that is both lightweight and strong, offers excellent resistance to corrosion in marine environments. It is commonly utilized in the construction of various marine vessels, including boats, ships, and yachts. The use of aluminum sheets in marine vessel construction has a significant advantage in terms of its high strength-to-weight ratio. This allows for the creation of lighter vessels, which can lead to improved fuel efficiency, increased speed, and enhanced handling. Additionally, the lightweight nature of aluminum facilitates easier transportation and maneuverability during the construction process. Another notable benefit of utilizing aluminum sheets for marine vessel construction is their exceptional resistance to corrosion. Aluminum naturally develops a protective oxide layer on its surface, which prevents further oxidation and corrosion. This makes aluminum an ideal choice for marine environments, where vessels are constantly exposed to saltwater, humidity, and other corrosive elements. Moreover, aluminum sheets can be easily fabricated and welded, providing flexibility in the design and construction of marine vessels. They can be shaped into various forms, allowing for the creation of intricate hull structures and interior components. Aluminum also possesses good thermal conductivity, which aids in regulating temperature within the interior spaces of marine vessels. While aluminum sheets offer numerous advantages for marine vessel construction, it is important to consider certain factors. Aluminum is susceptible to galvanic corrosion when it comes into contact with certain metals, such as steel or bronze. Therefore, proper insulation and anti-corrosion measures should be implemented to prevent galvanic corrosion in aluminum-based vessels. In conclusion, aluminum sheets are highly suitable for marine vessel construction. Their lightweight nature, high strength-to-weight ratio, resistance to corrosion, and ease of fabrication make them an ideal choice for building durable and efficient marine vessels. However, it is crucial to take proper precautions to prevent galvanic corrosion when aluminum is used alongside other metals.

Send your message to us

Aluminum Composite Sheets for Open Air Outer Decoration Aluminium Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords