Aluminum Alloy Door and Window Profiles for Power Amplifier Aluminum Heat Sink Aluminum Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Heat Sink Aluminum Profile for Power Amplifier

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Aluminum Heat Sink Aluminum Profile for Power Amplifier

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminum Heat Sink Aluminum Profile for Power Amplifier

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

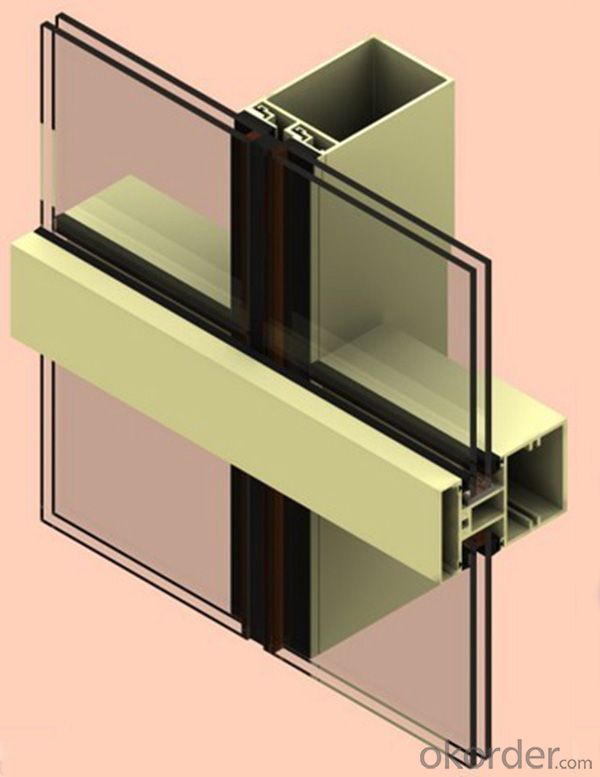

5. Image of Aluminum Heat Sink Aluminum Profile for Power Amplifier

6. Package and shipping of Aluminum Heat Sink Aluminum Profile for Power Amplifier

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: Can aluminum profiles be used in transportation and logistics applications?

- Yes, aluminum profiles are commonly used in transportation and logistics applications. Aluminum profiles are lightweight yet strong, making them an ideal choice for various components in the transportation and logistics industry. In the automotive sector, aluminum profiles are used in the manufacturing of car frames, chassis, and body panels. Their lightweight nature helps reduce the overall weight of the vehicle, resulting in improved fuel efficiency and lower emissions. Additionally, aluminum profiles offer excellent corrosion resistance, ensuring the longevity of the vehicle in harsh environmental conditions. In the aerospace industry, aluminum profiles are extensively used in the construction of aircraft structures, such as wings, fuselage, and landing gear. The high strength-to-weight ratio of aluminum profiles allows for increased payload capacity and fuel efficiency. Moreover, aluminum profiles can withstand extreme temperature variations and have good electrical conductivity, making them suitable for various aerospace applications. In the logistics sector, aluminum profiles are used for constructing cargo containers, pallets, and storage racks. The lightweight nature of aluminum profiles facilitates easy handling and transportation of goods. Additionally, aluminum profiles offer high resistance to rust and corrosion, ensuring the durability of logistics equipment even in humid or corrosive environments. Furthermore, aluminum profiles can be easily customized and fabricated to meet specific design requirements in transportation and logistics applications. They can be extruded into various shapes and sizes, allowing for versatility in design and functionality. Moreover, aluminum profiles can be joined using various methods like welding or fastening, providing flexibility in assembly and maintenance. In conclusion, aluminum profiles are indeed suitable for transportation and logistics applications due to their lightweight, strength, corrosion resistance, and versatility. They offer numerous benefits such as improved fuel efficiency, increased payload capacity, and durability in harsh environments. Thus, aluminum profiles are widely used in automotive, aerospace, and logistics industries for various components, contributing to the efficiency and reliability of transportation and logistics systems.

- Q: Ask you, China aluminum plate production factory, supply distribution in the provinces in which the details, please.

- A large share of the domestic market, mainly in Shanghai, Guangdong, Chongqing and other provinces and cities, the other areas are relatively small.From the regional distribution, aluminum production in East China is the highest, followed by South Central China. The provinces and municipalities in Jiangsu, Zhejiang, Guangdong and Chongqing have the highest output.Fengcheng global resource recycling technology development Co., Ltd.

- Q: What is the difference between aluminum profile and sheet metal?

- Aluminum extrusions can be produced by extrusion or casting. In contrast, the aluminum sheet is flat, mainly for all types of surface.

- Q: What are the aluminum profile manufacturers in Jiangsu?

- I saw a lot of aluminum profile manufacturers on Yi's housekeeper

- Q: Who can tell me the latest national standard for aluminum and the latest edition, -2008?

- Standard number: GB 21351-2008Standard Name: energy consumption quota for aluminum alloy building profile products per unitStandard status: currentEnglish: The, norm, of, energy, consumption, per, unit, product, of, wrought, aluminium,, alloy, extruded, architecture, profiles, for,...Date of implementation: 2008-6-1Promulgated by the Ministry of State Administration of quality supervision, inspection and Quarantine of the People's Republic of China, China National Standardization AdministrationBrief introduction: this standard specifies the Aluminum Alloy profile building energy consumption per unit product of the technical requirements, the scope of statistics and calculation method, calculation range and energy saving management measures. And the calculation and assessment of this standard applies to the enterprise energy consumption per unit product of Aluminum Alloy section building, and the consumption of the new project control.

- Q: What are the differences between standard and non - standard shapes?

- Hello, not within the scope of the national standard, so it is called non-standard,The standard piece is within the national standardThat's the difference,This GB standard can be found, are unified

- Q: How do aluminum profiles resist corrosion?

- Aluminum profiles have a natural resistance to corrosion due to the formation of a protective oxide layer on their surface. When exposed to oxygen in the air, aluminum reacts and forms a thin layer of aluminum oxide. This oxide layer acts as a barrier, preventing further oxidation and corrosion of the metal underneath. The oxide layer is tightly bonded to the aluminum surface, making it extremely durable and resistant to environmental elements such as moisture, chemicals, and UV radiation. Additionally, aluminum profiles can be further enhanced with various surface treatments such as anodizing or powder coating, which provide an additional layer of protection against corrosion. These treatments not only enhance the aesthetic appeal of the profiles but also improve their resistance to corrosion, making them suitable for a wide range of applications in various industries. Overall, the natural oxide layer and the ability to apply additional protective coatings make aluminum profiles highly resistant to corrosion, ensuring their longevity and durability in different environments.

- Q: How do aluminum profiles perform in terms of creep resistance?

- Aluminum profiles generally exhibit good creep resistance. Creep is the tendency of a material to deform under constant load over time. Aluminum profiles tend to have a low creep rate compared to other materials, making them suitable for applications where long-term structural stability is required. The high strength-to-weight ratio of aluminum profiles also contributes to their creep resistance, as they can withstand heavy loads without significant deformation. However, it is important to note that the creep resistance of aluminum profiles can be influenced by various factors such as alloy composition, heat treatment, and operating conditions. Proper design and engineering considerations should be taken into account to ensure optimal creep performance in specific applications.

- Q: Are aluminum profiles suitable for use in mining and construction equipment?

- Indeed, mining and construction equipment can benefit from the utilization of aluminum profiles. The unique properties of aluminum make it highly compatible with these industries. Firstly, its lightweight nature aids in reducing the overall weight of the equipment, facilitating easy transportation and maneuverability on construction sites or during mining operations. Moreover, this lightweight characteristic enhances fuel efficiency, thereby decreasing operational costs. Furthermore, aluminum profiles possess exceptional resistance to corrosion, a vital attribute for these industries, where equipment is frequently exposed to severe weather conditions and corrosive substances. This corrosion resistance guarantees the durability and longevity of the equipment, even in challenging environments. Additionally, aluminum profiles offer ease of fabrication and customization to cater to specific requirements. This adaptability in design permits the creation of intricate shapes and structures, enabling the construction of equipment with optimal strength and functionality. Moreover, the high thermal conductivity of aluminum profiles effectively dissipates heat generated during mining and construction operations. This property plays a crucial role in preventing overheating or damage to the equipment, ensuring efficient performance even in intense working conditions. In summary, the combination of lightweight, corrosion resistance, versatility, and thermal conductivity renders aluminum profiles a suitable choice for integration into mining and construction equipment.

- Q: Are aluminum profiles suitable for food processing or storage facilities?

- Aluminum profiles prove to be suitable for food processing or storage facilities. In these environments, aluminum, being a highly versatile material, offers numerous advantages. To begin with, aluminum's corrosion resistance guarantees its resilience against moisture, food acids, and commonly used cleaning agents in food facilities. Consequently, it becomes an ideal choice for areas where hygiene and cleanliness hold paramount importance. Moreover, aluminum profiles possess the unique characteristic of being lightweight yet sturdy, rendering them easily manageable and installable. This feature proves particularly advantageous in food processing facilities that necessitate regular equipment maintenance and reconfigurations. In addition, aluminum serves as a non-toxic material, ensuring that it does not taint food products during the processing or storage stages. Furthermore, its exceptional heat conductivity enables efficient temperature control within processing facilities. Furthermore, aluminum profiles can be effortlessly cleaned and sanitized. This not only diminishes the risk of bacterial growth but also ensures compliance with food safety regulations. In conclusion, the durability, corrosion resistance, lightweight nature, non-toxicity, and ease of maintenance collectively establish aluminum profiles as an exceptional choice for food processing or storage facilities.

Send your message to us

Aluminum Alloy Door and Window Profiles for Power Amplifier Aluminum Heat Sink Aluminum Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords