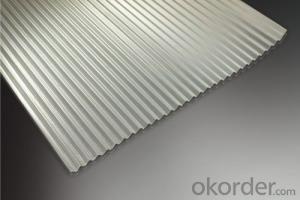

aluminum 4ft x 8ft sheets corrugated roofing sheet roof tile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification

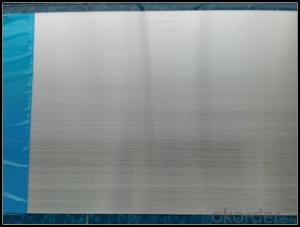

| commodity | aluminum 4ft x 8ft sheets corrugated steel roofing sheet color steel roof tile roofing |

Grade | SGCC SGCH DX51D |

Standard | ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008 AS1397-2001, EN10215-1995, ASTM A792M-02, JIS G3321-1998 |

Basal plate | Cold rolled steel coil ,hot dipped galvanized/galvalume steel coil |

Zinc Coating | Z30-Z275G/m2, AZ30-150g/m2 |

Thickness | 0.13-0.9mm |

Width | 750-1250mm(before corrugation) 600-1050mm(after corrugation) |

Wave depth | 18(+/-2mm),etc |

Wave distance | 76(+/-2mm),etc |

| color | according to RAL |

| length | as your requestment |

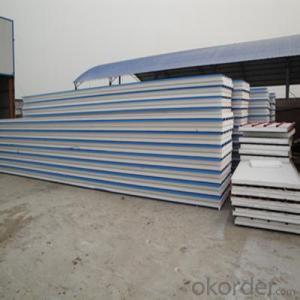

| Product feature | water resistance,light weight,easy installation,aesthetic,high tensile |

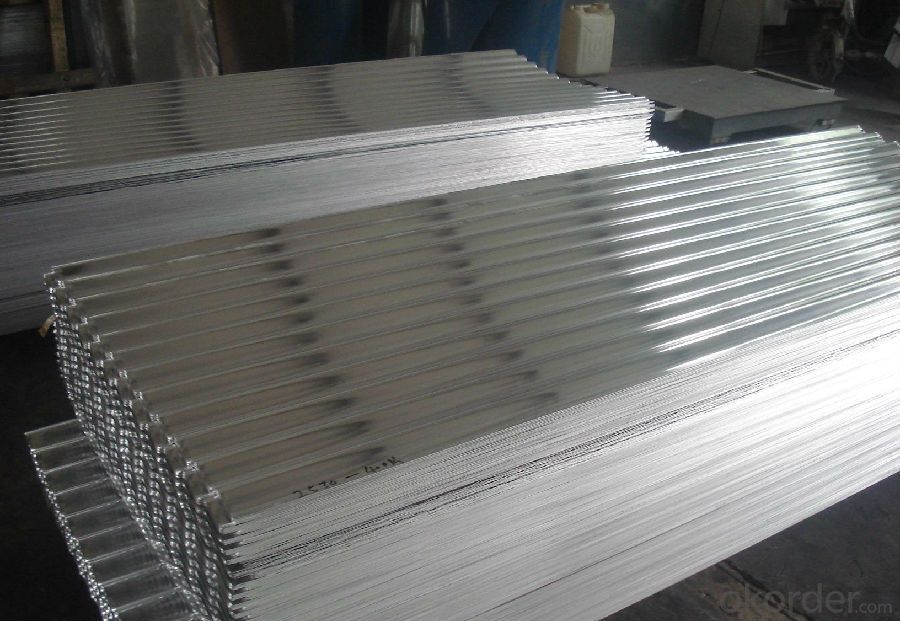

| Packing | standard export water-proof package with steel strips fixed |

| Coating | Top:10-25um back:5-10um |

| Application | exterior and interior wall,roofs,and soffits |

| Advantages | 1.Design according to customers 'requirements 2.Production under ISO9001-2008 Quality System 3.Easy to be installed as light weight 4.Z360-275/AZ30-150 is suitable for many application 5.Our products are recyclable materials 6.The less construction period, the more using time. |

Production line

We have six producting line of color aluminum tile. Our annual output is 8000 ton,due to the most advanced and mordern lines

why choose us

our advantage of color steel tile

1.corrosion resistance

2.light weight:Metal covered and metal frame buildings offer the safest possible shelter during the storms. Correctly earthed aluminium, because of its high electrical conductivity, offers excellent protection from lighting damage.

3.High strength:bending and compression resistance, used as building enclosure and bearing structure

4.Easy to install:no need special tools, do not break, crack or leak.

5.Energy-saving:saving of the structural steel by up to 40%.

6.Beautiful design

7.Quake-proof, fire-proof, rain-proof.

8.It can be recycled and good for environments.

our service for you

pre-sale service

1.sample free

2.We have full stock and can deliver within short time

3.Dood quality+factory price+quick response+reliable service

4.All of our products are produce by our professional workman and we have our high-work-effect foreign trade team, you can totally believe our service.

After you choose

1.we will count cheapest shipping cost and make invoice to you at once

2.check quality again,then send out to you at 5-10 working day after your payment

3.email you the tracking No,and help to chase the parcels until it arrive you

After sale choose

1.we are very glad that customer give us some suggestion for price and products

2.If any question,please contact with us freely by E-mail or telephone

Our products are very popular to be exported to the Russian market,Korea South-East Asia,India,Middle-East,Africa,North-Europe,South- America,and so on.

- Q: Can aluminum sheets be coated with other materials?

- Yes, aluminum sheets can be coated with other materials. This process is known as aluminum sheet coating or aluminum sheet finishing. Coating aluminum sheets with other materials serves multiple purposes, such as enhancing their appearance, protecting against corrosion, improving durability, and providing insulation. There are various methods to coat aluminum sheets, including painting, anodizing, laminating, and powder coating. Each method offers different benefits and is chosen based on the desired outcome and intended use of the coated aluminum sheet. Coating aluminum sheets with other materials allows for customization, versatility, and increased functionality in a wide range of applications, including construction, automotive, aerospace, and consumer goods industries.

- Q: This question asks for a list of various coatings that can be applied to aluminum sheets for different purposes.

- <p>Aluminum sheets can be coated with a variety of materials to enhance their properties such as durability, appearance, and corrosion resistance. Some common types of coatings include: 1. Anodizing: Creates a protective oxide layer on the aluminum surface. 2. Powder Coating: A dry coating that is electrostatically applied and then cured at high temperatures. 3. PVDF (Polyvinylidene Fluoride) Coating: Known for its excellent resistance to UV, chemicals, and weathering. 4. Epoxy Coating: Provides a hard, durable finish that is resistant to chemicals and corrosion. 5. Polyester Coating: Offers good adhesion and is often used for outdoor applications. 6. Fluorocarbon Coating: Provides a high level of durability and resistance to weathering. 7. Ceramic Coating: A newer type of coating that offers excellent heat resistance and a smooth finish. These coatings are chosen based on the specific requirements of the application, such as architectural, automotive, or aerospace uses.</p>

- Q: What are the different types of patterns available for aluminum sheets?

- Aluminum sheets come in a wide range of patterns, each with its own unique visual and functional appeal. Here are some popular patterns that you can find: 1. Diamond Pattern: This pattern features raised diamonds created by intersecting parallel lines at 60-degree angles. It offers excellent slip resistance and is commonly used for flooring, stairs, and walkways. 2. Stucco Pattern: The stucco pattern mimics the texture of traditional stucco plaster, with a pebble-like surface. It provides enhanced durability and is often used decoratively on walls, ceilings, and interior panels. 3. Hammered Pattern: The hammered pattern creates a rustic and artistic appearance with its dimpled texture. It is frequently used for decorative purposes, such as wall cladding or furniture accents. 4. Perforated Pattern: Perforated aluminum sheets have small holes that offer great ventilation and visibility. They are commonly used in architectural applications like facades, sunscreens, and noise barriers. 5. Embossed Pattern: The embossed pattern adds depth and visual interest with raised designs or patterns on the sheet's surface. It is ideal for decorative purposes, signage, and branding applications. 6. Brushed Pattern: The brushed pattern creates a sleek and modern look by giving the aluminum sheet a uniform directional grain. It is often used for architectural accents, kitchen backsplashes, and appliances. 7. Ribbed Pattern: The ribbed pattern features parallel raised ridges or lines on the sheet's surface, offering improved strength and rigidity. It is suitable for applications that require structural support or reinforcement. These examples showcase the variety of patterns available for aluminum sheets. When selecting the right pattern for a specific application, it is essential to consider the specific requirements and desired aesthetic.

- Q: Does aluminum sheet require special handling during transportation?

- Yes, aluminum sheets typically require special handling during transportation. This is because aluminum is a lightweight yet fragile material that can easily dent, scratch, or bend. To prevent such damages, it is important to handle aluminum sheets with care, avoiding rough handling, excessive bending, or stacking heavy objects on top. Additionally, protective measures like using padding or wrapping the sheets in protective material can help ensure their safe transportation.

- Q: I need help with this question for a report i'm doing, it's about recycling aluminium, please could you give me some reasons why to recycle aluminium and eg.saves energy, and how it does eg. saves energy by...Thanks a lot this will help me loads.P.S this is just a report for my science project.

- Mining of metals causes huge environmental damage, polluting water and using vast amounts of energy which has a large environmental cost. savingiceland.puscii.nl/?language... This is an activist site fighting Aluminium mining in Iceland. Metals like oil and other materials are also finite, they are not endless, so they're getting more expensive and may run out. Metals are very useful and shouldn't be wasted. I always pick up ally cans in the street and put them in the nearest recycling bin.

- Q: Can aluminum sheets be anodized with custom colors?

- Custom colors can indeed be applied to aluminum sheets through the process of anodizing. Anodizing involves the application of an electrochemical procedure that adds a protective oxide layer to the aluminum's surface, thereby enhancing its durability and resistance to corrosion. In this process, the aluminum sheet is submerged in an electrolytic solution while an electrical current is passed through it. This induces a controlled oxidation of the aluminum's surface, leading to the formation of a porous layer that can be colored with dyes to achieve desired shades and hues. By carefully selecting the appropriate dye, a wide array of custom color options can be achieved. Moreover, anodized aluminum sheets offer versatility as they can undergo additional treatments like laser engraving or printing to create distinctive designs and patterns. Therefore, they are highly suitable for a diverse range of applications in industries such as architecture, automotive, and electronics.

- Q: What are the fire resistance properties of aluminum sheets?

- Aluminum sheets exhibit excellent fire resistance properties due to their high melting point and low thermal conductivity. Aluminum has a melting point of approximately 660 degrees Celsius, which is significantly higher than other commonly used metals like steel. This means that aluminum sheets can withstand high temperatures without melting or losing their structural integrity. Additionally, aluminum has a low thermal conductivity, which means it does not transfer heat easily. This property helps to prevent the spread of fire and limits the heat transfer to adjacent areas. Moreover, aluminum does not produce toxic gases or emit hazardous fumes when exposed to fire, making it a safe material in fire-prone environments. These fire-resistant properties make aluminum sheets a popular choice for various applications where fire safety is a concern, such as in the construction of aircraft, buildings, and automotive components.

- Q: Can aluminum sheets be laser cut?

- Yes, aluminum sheets can be laser cut. Laser cutting is a popular method for cutting aluminum sheets due to its precision and efficiency. The laser cutting process involves using a high-powered laser to melt or vaporize the material, creating a clean and accurate cut. Aluminum is a highly reflective material, so it requires a higher-powered laser to effectively cut through it. However, once the correct laser settings are determined, aluminum sheets can be easily and precisely cut using a laser cutting machine. This method is widely used in industries such as automotive, aerospace, and manufacturing for various applications involving aluminum sheets.

- Q: Can aluminum sheets be used for electronic enclosures?

- Indeed, electronic enclosures can make use of aluminum sheets. The remarkable characteristics of aluminum make it a frequently employed material for electronic enclosures. Its lightweight nature, resistance to corrosion, and ability to provide effective electromagnetic shielding are among its outstanding attributes. Aluminum sheets can be effortlessly shaped and crafted into diverse dimensions and configurations, rendering them well-suited for accommodating electronic components. Moreover, aluminum boasts commendable thermal conductivity, enabling efficient dissipation of heat from the enclosed electronics. In summary, aluminum sheets are a favored option for electronic enclosures owing to their durability, adaptability, and electrical properties.

- Q: is steel better for making bicycle frames.....how does it differ from the aluminum framed bikes?

- Unless you are an all star pro, a steel bike will suit you fine. Thing is, the difference in weight is so small that unless you are racing people in multi-national competitions, it's just a lot of extra money you could put into buying a REALLY nice steel frame. Don't let ads fool you, steel are just as good as aluminum.

Send your message to us

aluminum 4ft x 8ft sheets corrugated roofing sheet roof tile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords