Color Corrugated Steel Roof Panels in Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

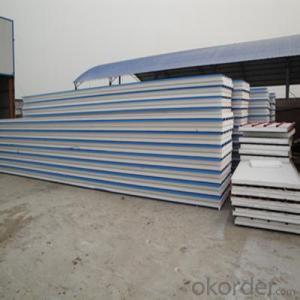

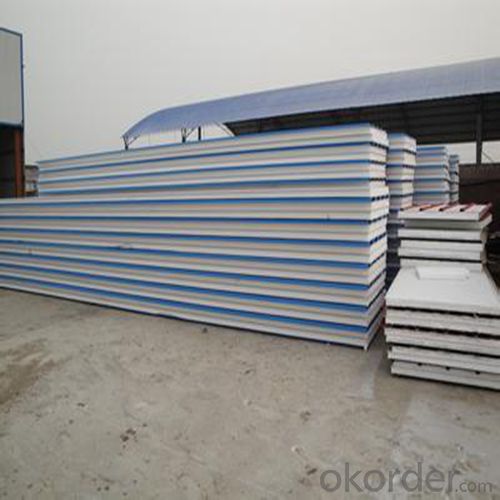

High Quality Polyurethane Sandwich Panels for Roof,Wall and Cold Storage

1.Structure of Sandwich Panel

Sandwich panel is composed of 2 layers of weather-proof colored steel sheets and jetted the hard forms of polyurethane between 2 layers which feature fireproof materials. Sandwich panel is suitable for the various roofs and walls referring to the large-size factory buildings, storages, exhibition halls, gymnasiums, freezing stores, purifications workshops, etc, Sandwich panel has features temp-keeping, heat insulation, weight-bearing, weatherproof with the rich colorfulness and good appearance.

2.Main Features of the Sandwich Panel

1) Our EPS sandwich panel has the following characteristics:light dead weight, high mechanical strength, excellent shearing resistant performance, strong corrosion resistance, high durability, and weather fastness, etc.

2) The sandwich panel has excellent insulating performance: heat insulation, sound insulation, waterproof performance, etc.

3) It is easy to install and can be used many times over.

4) Nowadays, the EPS sandwich panel is widely used for cleaning workshops, industrial factory buildings, office buildings, stadiums, villas, and public buildings, etc.

5) Apart from EPS sandwich panels, Wiskind also offers rock wool sandwich panels, glass wool sandwich panels, PU sandwich panels, honeycomb sandwich panels.

6) These products have all passed ISO9001 and ISO14001 certification. Due to their high quality and low price, they are well received by our customers in Russia, Australia, Angola, Congo, and Korea, etc.

3. Sandwich Panel Images

4. Sandwich Panel l Specification

Effective width Wall panel: 950mm 1150mm 1200mm Roof panel: 950mm 980mm

Length According to customer's request

Materials Polystyrene foam board(EPS), Color steel sheet

Structure Upper and lower layer: Color steel sheet

Middle: polystyrene foam board

Thickness Color steel sheet: 0.3-0.6mm

Polystyrene foam board: 50mm 75mm 100mm 150mm 200mm

The polystyrene density 8-20kg/m3

Conventional color RAL standard

Character Light in weight, heat insulation, water resistant, green and environmental

Use various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc.

5.Advantages of Sandwich Panels

1) Heat and sound insulation: The outer steel sheets can maintain the lastingness of the color of the building, and reduce the solar radiation and keep the appropriate indoor temperature. The high quality heat insulation materials are made with the adoption of polyurethane PU and (PIR) polyisocyanurate resin acid hydrogen containing no Chloro-fluoro-carbons (CFC).

2) A degree inflaming retarding: This system can effectively prevent the fire and prevent the fire from spreading during the cross construction and during the use of the boards

3) Environment protection: By learning after the successful experience in environment protection constructions from companies home and abroad and through our scientific analysis, we objectively bear the idea of “low carbon designing, environmental building materials and energy-saving technology” in mind.

4) Super-low heat conductivity: The lowest heat conducting coefficient of the heat insulation boards ensures that, under the condition that the thinnest heat insulation materials are used; the system can meet the energy-saving requirement and offer the strongest basic guarantee to meet the requirement of high standard heat insulation

5) Easily and quick installation

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

2) A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

3) How to guarantee the quality of the products?

4) We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5) How long can we receive the product after purchase?

6) In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Can steel sheets be painted or powder-coated after installation?

- Yes, steel sheets can be painted or powder-coated after installation. This allows for customization and protection against corrosion or other environmental factors.

- Q: Are the steel sheets resistant to vibration or shock?

- Steel sheets are generally resistant to vibration and shock due to their high strength and durability. Steel is known for its ability to withstand external forces like vibrations and shocks, thanks to its rigid nature. This allows steel to effectively absorb and distribute energy caused by vibrations or shocks, preventing any significant damage or deformation. In various industries, such as construction, automotive, and aerospace, steel sheets are commonly used because their resistance to vibrations and shocks is crucial. However, it's important to consider that the exact resistance of steel sheets to vibration or shock depends on factors like thickness, steel quality, and the specific magnitude and frequency of the vibrations or shocks.

- Q: What are the different sheet metal rolling techniques for steel sheets?

- Steel sheets can be rolled using different techniques, including hot rolling, cold rolling, and roll forming. Hot rolling involves heating steel sheets above their recrystallization temperature and passing them through rollers to reduce thickness. This method is commonly used to produce steel sheets with consistent thickness and improved mechanical properties. In contrast, cold rolling rolls steel sheets at room temperature. This process creates thinner and smoother sheets with higher dimensional accuracy. Cold-rolled steel is often used for applications that require a high-quality surface finish, such as automotive body panels and appliances. Roll forming is a continuous bending process where a long strip of steel is gradually shaped into a desired profile using rollers. This technique is suitable for producing steel sheets with complex shapes and profiles, like corrugated roofing or C-channel beams. Roll forming offers excellent precision and repeatability, making it a popular choice for mass producing steel sheets with consistent dimensions. Ultimately, the choice of rolling technique depends on the specific requirements of the application. Hot rolling is ideal for achieving uniform thickness and improved mechanical properties. Cold rolling is preferred for applications that demand high-quality surface finish and dimensional accuracy. Roll forming is suitable for creating steel sheets with complex shapes and profiles.

- Q: What is the difference between a brushed and polished steel sheet?

- A brushed steel sheet and a polished steel sheet differ in terms of their surface finishes. A brushed steel sheet is characterized by a pattern of parallel lines or scratches on its surface, created using abrasive materials or tools. The purpose of brushing is to give the steel sheet a textured appearance, which helps to hide fingerprints, scratches, and wear over time. It also provides a more industrial, matte finish. On the other hand, a polished steel sheet has a smooth and glossy surface. Polishing involves using polishing compounds or abrasive materials to remove imperfections, scratches, and oxidation from the steel surface. This process creates a reflective and mirror-like finish, enhancing the aesthetic appeal of the steel sheet. Polished steel sheets are commonly used in applications where appearance and visual appeal are important, such as architectural design, interior decoration, and high-end products. In summary, the main difference between a brushed and polished steel sheet lies in their surface finishes. Brushed steel sheets have a textured, matte appearance, while polished steel sheets have a smooth and glossy, mirror-like finish. The choice between the two depends on the desired aesthetic, functional requirements, and the intended application of the steel sheet.

- Q: What are the different sheet metal cutting techniques for steel sheets?

- There are several different sheet metal cutting techniques that can be used specifically for steel sheets. Here are some commonly used methods: 1. Shearing: This is a traditional method where a shear or a pair of blades is used to cut the steel sheet by applying a high force. It is ideal for straight cuts and can be used for both thin and thick steel sheets. 2. Laser cutting: This technique uses a high-powered laser beam to cut through the steel sheet. It offers high precision and can create intricate designs. Laser cutting is suitable for both thin and thick steel sheets. 3. Plasma cutting: Plasma cutting involves the use of a plasma torch that generates an electrically conductive jet of plasma to cut through the steel. It is commonly used for thick steel sheets and offers fast cutting speeds. 4. Waterjet cutting: In this method, a high-pressure jet of water mixed with abrasive particles is used to cut through the steel sheet. Waterjet cutting is versatile and can handle various thicknesses of steel sheets. It is also suitable for cutting heat-sensitive materials. 5. Punching: Punching involves using a punch and die set to create holes or other shapes in the steel sheet. It is a cost-effective method for repetitive cuts and can be used for both thin and thick steel sheets. 6. Abrasive cutting: This technique uses an abrasive wheel or disc to grind through the steel sheet. It is typically used for thin steel sheets and provides a smooth finish. The choice of cutting technique depends on factors such as the thickness of the steel sheet, required precision, complexity of the design, and the material's heat sensitivity. Each technique has its advantages and limitations, so it is important to consider these factors when selecting the appropriate method for cutting steel sheets.

- Q: What are the different types of coatings available for steel sheets?

- There are several types of coatings available for steel sheets, including galvanized coatings, which involve applying a layer of zinc to protect against corrosion; metallic coatings, such as aluminum or tin, which provide a barrier against corrosion; organic coatings, including paints and polymers, which offer both protection and aesthetic appeal; and ceramic coatings, which provide high-temperature resistance and can be used in extreme environments.

- Q: What is the difference between a galvalume and galvanized steel sheet?

- The main difference between a galvalume and galvanized steel sheet lies in the coating applied to the steel. Galvalume uses a combination of aluminum, zinc, and silicon to form a protective coating, while galvanized steel is coated with a layer of zinc. This difference in coating composition gives galvalume sheets better corrosion resistance, heat reflectivity, and durability compared to galvanized steel.

- Q: What is the weight of steel sheets?

- The weight of steel sheets can vary depending on their size, thickness, and density. However, on average, steel sheets can range from a few pounds to several hundred pounds per square foot.

- Q: What is the average bending radius for steel sheets?

- The bending radius of steel sheets is subject to variation depending on factors such as thickness, grade, and steel type. Nevertheless, in the case of mild steel sheets, the minimum bending radius typically equates to roughly four times the sheet thickness. To illustrate, if the sheet thickness measures 1.6mm, the minimum bending radius would be approximately 6.4mm. It is crucial to recognize that this serves as a general principle, and particular bending specifications may deviate depending on the intended application and desired result.

- Q: What is the average wind load capacity of steel sheets?

- The average wind load capacity of steel sheets can vary depending on various factors such as the thickness of the sheet, the type of steel used, and the specific design and installation of the structure. However, steel sheets are known for their high strength and durability, making them capable of withstanding significant wind loads. Typically, steel sheets used for roofing or cladding applications are designed to meet specific wind load requirements based on regional building codes and standards. These standards take into account factors such as the geographical location, building height, exposure category, and wind speed. To determine the wind load capacity of steel sheets, engineers and architects use calculations and simulations to analyze the forces exerted by the wind on the structure. They consider factors such as wind pressure, building orientation, surface area, and the shape and profile of the steel sheets. In summary, the average wind load capacity of steel sheets cannot be generalized as it varies based on several factors. It is crucial to consult with a structural engineer or building professional to determine the appropriate wind load capacity requirements for a specific steel sheet application.

Send your message to us

Color Corrugated Steel Roof Panels in Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords