4 By 8 Aluminum Sheets - Aluminium Corrugated Roofing Sheets PP Corrugated Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.2~320mm |

Width | <2800mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Payment | L/C ,T/T |

Brief Introduction for Cold Rolled Steel Coil

Cold Rolled Steel Coil is steel that has been worked below its recrystallization temperature by passing it between a pair of rollers. Recrystallization temperature is the temperature at which grains in the lattice structure of the metal have been rearranged, leaving it free of strain and deformations. Cold Rolled Steel Coil is pre-treated before being cold rolled with a process known as pickling, which uses strong acids to remove scale and other impurities. The Cold Rolled Steel Coil is then passed through rollers to reduce its thickness. Most cold rolling takes place in multiple passes and as the size of the Cold Rolled Steel Coil is further reduced, its strength and hardness both increase, but its ductility decreases. After cold rolling, heating the metal up in a process known as annealing can restore some of its ductility. The final Cold Rolled Steel Coil may be manufactured in the form of sheets, strips, bars, or other forms.

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

Our Services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3. We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

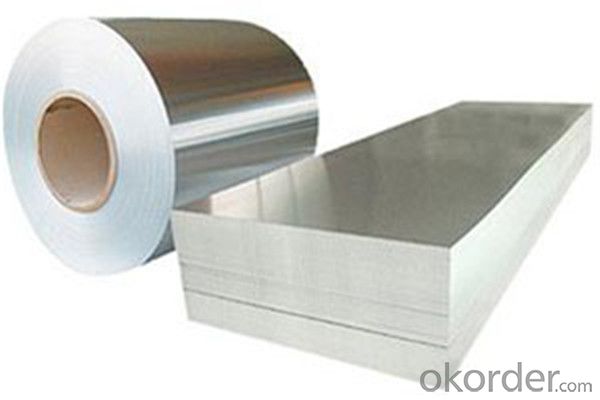

Photos of products

- Q: Can aluminum sheets be used as heat shields?

- Yes, aluminum sheets can be used as heat shields. Aluminum has high thermal conductivity, which means it can effectively absorb and distribute heat, making it an excellent material for heat protection. It is commonly used in various applications such as automotive, aerospace, and industrial settings to shield sensitive components from high temperatures.

- Q: what's the temperature tolerance of aluminum sheets?

- aluminum is a kind of silver white metal,melting point:660.4℃, boiling point: 2467℃,density: 2.70 g/cm?,very light, about 1/4 of iron's density.it has low hardness and good ductility, which makes it suitable for being pulled into threadlets or pressed into aluminum foils, and the later is usually used for packaging candy and cigarette. it has good electrical and temperature conductivity. it's used for the manufacture of electric wire and cable in electric power industry, and for the manufacture of cooker in daily life bined with the magnesium , copper,zinc,tin,manganese,chromium,zirconium,silicon and other elments,it can formulate various alloys that is broadly used for the manufacture of airplane,car,ship, materials of daily living equipment and the doors and windows of construction industry.aluminum is one of the best reflectors of heat and light, so it is used as thermal insulation material and the manufacture of reflecting mirror in the reflecting telescope.

- Q: Can the aluminum sheets be used for soundproofing applications?

- Indeed, soundproofing applications can make use of aluminum sheets. As a lightweight and immensely reflective substance, aluminum possesses the capability to effectively obstruct and absorb sound waves. By incorporating aluminum sheets into soundproofing endeavors, one can contribute to the reduction of noise transmission and the creation of a more serene atmosphere. These sheets can be employed as barriers, panels, or even as constituents of composite materials to augment soundproofing attributes. Moreover, aluminum sheets exhibit durability, resistance to corrosion, and ease of upkeep, rendering them fitting for sustained utilization in diverse soundproofing applications.

- Q: Can the aluminum sheets be used for manufacturing chemical reactors?

- Indeed, chemical reactors can be manufactured using aluminum sheets. Renowned for its exemplary resistance to corrosion and remarkable thermal conductivity, aluminum is a suitable option for diverse industrial purposes, including the production of chemical reactors. Moreover, aluminum possesses the advantage of being lightweight and malleable, facilitating the creation of reactors with varying sizes and configurations. Nevertheless, it is crucial to acknowledge that selecting the appropriate materials for chemical reactors hinges on the particular demands of the process and the chemicals employed. In certain instances, environments characterized by corrosiveness or high temperatures may necessitate the utilization of more specialized materials.

- Q: What is the fire rating of 101 aluminum sheets?

- The fire rating of 101 aluminum sheets is typically dependent on the particular alloy and thickness of the sheets. Due to its low melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum has the potential to deform or melt when exposed to intense heat. Nevertheless, it is important to highlight that aluminum is not flammable and does not aid in the propagation of fire. Fire resistance can be improved by applying fire-resistant coatings or by incorporating it with other fire-resistant substances. In conclusion, it is crucial to seek advice from manufacturers or industry professionals to ascertain the fire rating of specific 101 aluminum sheets.

- Q: i m not sure if aluminum hydroxide is a acid or base. if somebody could help me, i will really appreciate.If u can could you also tell me if im wrong or right about the following substances:- pepsi cola is acid- vinegar is a base- ammonia is a base- aluminum hydroxyde is ?thank u for your help.

- as stated anything ending in -OH is a base, therefore AlOH is a base. the others are correct except for vinegar, it is an acid, not a base.

- Q: What is the minimum bending radius for aluminum sheets?

- The minimum bending radius for aluminum sheets depends on several factors, including the thickness and alloy of the sheet, as well as the bending method being used. However, as a general guideline, the minimum bending radius for aluminum sheets is typically around 1.5 to 2 times the thickness of the sheet. For example, if you have a 1mm thick aluminum sheet, the minimum bending radius would be around 1.5 to 2mm. It is important to note that these values can vary, so it is always recommended to consult the specific material and bending guidelines provided by the manufacturer or a professional in the field to ensure optimal results.

- Q: This question asks for an explanation of the various grades of aluminum sheets and the distinctions between them.

- <p>Aluminum sheets are categorized into different grades based on their alloy composition, which affects their properties such as strength, formability, and corrosion resistance. Common grades include 1000 series (99.00% aluminum, soft and malleable), 2000 series (aluminum-copper alloys, strong and heat treatable), 3000 series (aluminum-manganese alloys, good formability), 5000 series (aluminum-magnesium alloys, good strength and corrosion resistance), and 6000 series (aluminum-silicone-magnesium alloys, good strength and extrudability). Each grade has specific applications based on its characteristics, with 1000 series used for general purposes, 2000 series for aircraft structures, 3000 series for decorative applications, 5000 series for marine environments, and 6000 series for structural components.</p>

- Q: Are the aluminum sheets suitable for HVAC (heating, ventilation, and air conditioning) applications?

- Yes, aluminum sheets are suitable for HVAC applications. Aluminum is a lightweight and corrosion-resistant material that is commonly used in HVAC systems due to its excellent thermal conductivity and durability. It is often used for ductwork, heat exchangers, and evaporator coils in HVAC systems.

- Q: Is aluminum sheet resistant to UV rays?

- Indeed, aluminum sheet exhibits resistance to UV rays. By nature, aluminum develops a safeguarding oxide layer which functions as a shield against UV radiation. This protective layer aids in safeguarding the aluminum sheet from harm or deterioration caused by the sun's UV rays. Consequently, aluminum sheet proves to be an appropriate material for outdoor usage, enduring extended exposure to sunlight without experiencing fading or deterioration. Moreover, the reflective characteristics of aluminum also contribute to its resistance against UV rays, as it can effectively reflect a considerable portion of the sun's rays, diminishing heat absorption and the likelihood of damage.

Send your message to us

4 By 8 Aluminum Sheets - Aluminium Corrugated Roofing Sheets PP Corrugated Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords