Thin Aluminum Sheets AA5754 for Making Aluminum Trailers - Home Depot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminium Sheets AA5754 for Making Aluminium Trailers

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Aluminium Sheets AA5754 for Making Aluminium Trailers

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminium Sheets AA5754 for Making Aluminium Trailers

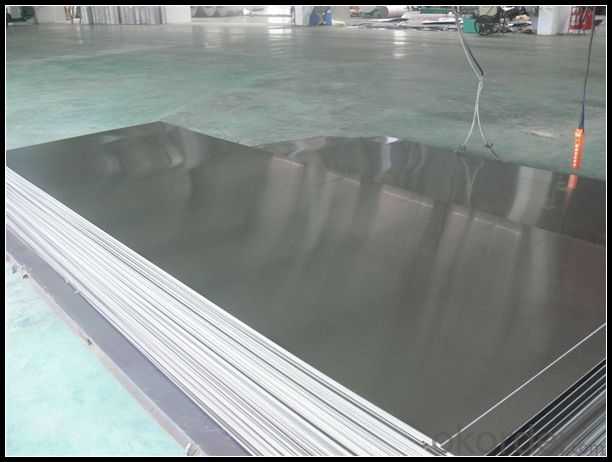

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

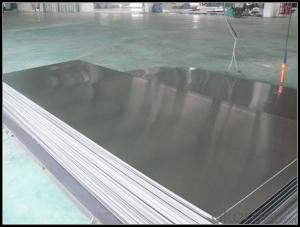

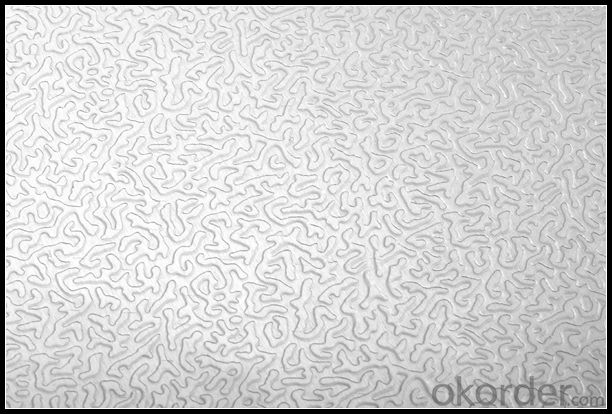

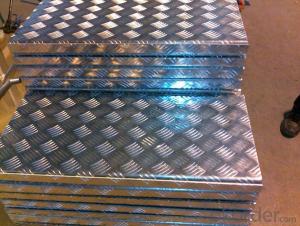

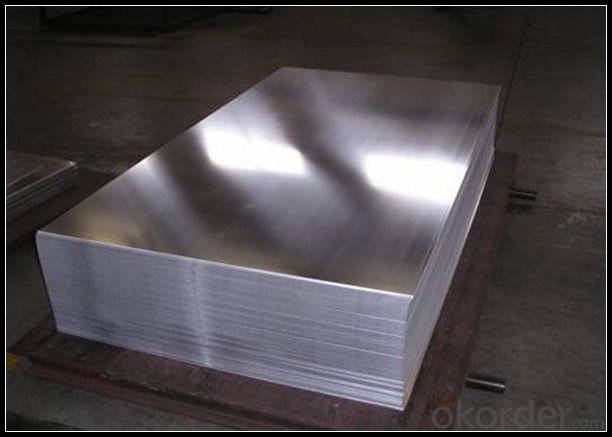

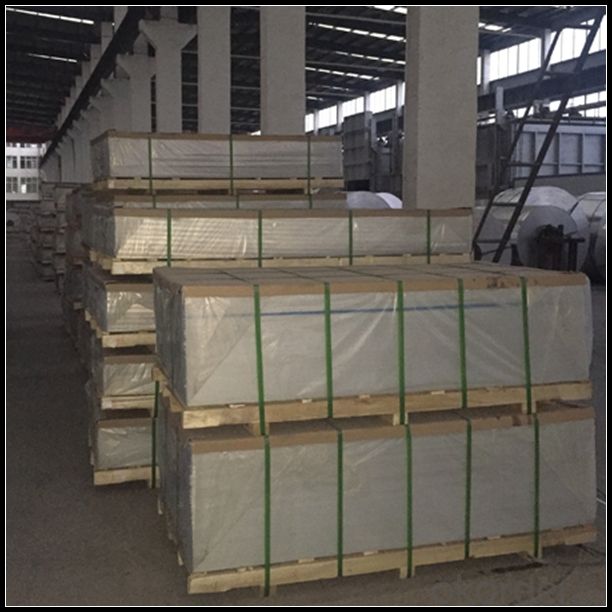

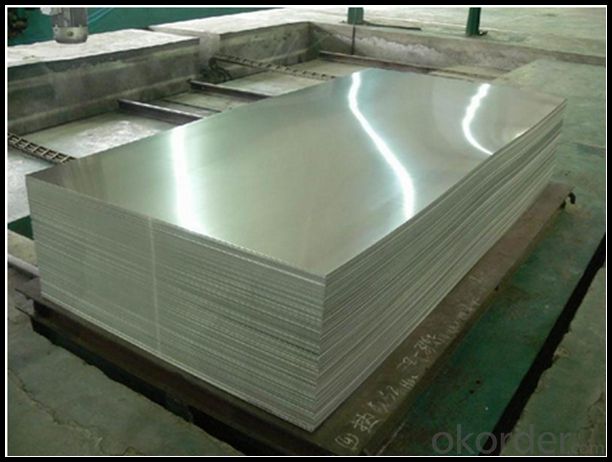

5. Image of Aluminium Sheets AA5754 for Making Aluminium Trailers

6. Package and shipping of Aluminium Sheets AA5754 for Making Aluminium Trailers

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks about the impact of aluminum sheets on the quality of air inside a building.

- <p>Aluminum sheets themselves do not directly affect indoor air quality in a building. They are inert materials that do not emit harmful gases or particles. However, the installation process may involve adhesives or sealants that could release volatile organic compounds (VOCs) temporarily, which can affect air quality. Proper ventilation during installation and after can mitigate this. Additionally, aluminum sheets can contribute to better air quality by providing a barrier against moisture and mold growth, which can be a concern with other building materials.</p>

- Q: Does aluminum sheet require special handling during transportation?

- Yes, aluminum sheet does require special handling during transportation. This is because aluminum sheets are lightweight and can be easily damaged if not handled properly. Special precautions need to be taken to prevent scratching, bending, or denting of the sheets. They should be packaged and secured in a way that minimizes movement and provides adequate protection against impacts. Additionally, aluminum sheets should be transported separately from other heavy objects or materials to avoid any potential damage caused by their weight. Overall, special care and attention must be given to ensure the safe transportation of aluminum sheets.

- Q: Can the aluminum sheets be used for manufacturing furniture?

- Yes, aluminum sheets can certainly be used for manufacturing furniture. Aluminum is a lightweight and strong material, making it ideal for creating furniture that is both durable and easy to move around. Additionally, aluminum is resistant to corrosion, so it can withstand exposure to various environmental conditions. Moreover, aluminum sheets can be easily shaped and formed into different designs, allowing for versatility in furniture manufacturing. Overall, using aluminum sheets for furniture manufacturing can result in high-quality, stylish, and long-lasting pieces.

- Q: Are aluminum sheets non-magnetic?

- No, aluminum sheets are not magnetic.

- Q: Can aluminum sheets be laminated with other materials?

- Indeed, it is possible to laminate aluminum sheets with alternative substances. Lamination denotes the fusion of multiple layers of diverse materials, thereby yielding a composite material that possesses heightened qualities. Aluminum sheets can be laminated with a variety of materials, including plastics, fabrics, papers, or other metals, through the utilization of either adhesive bonding or the application of heat and pressure. This process of lamination facilitates the amalgamation of favorable attributes from distinct materials, ultimately yielding a final product that exhibits elevated strength, durability, appearance, or specific functionality. Laminated aluminum sheets find widespread employment in industries such as construction, automotive, aerospace, and packaging, where the amalgamated properties of the laminated substances confer distinct advantages.

- Q: Are aluminum sheets suitable for construction applications?

- Yes, aluminum sheets are suitable for construction applications. Aluminum is a lightweight and durable material that offers several advantages in construction projects. It has high strength-to-weight ratio, making it easy to handle and transport while still providing excellent structural integrity. Aluminum sheets are corrosion-resistant, which makes them ideal for outdoor applications. They can withstand exposure to harsh weather conditions, such as rain, snow, and UV rays, without deteriorating or rusting. This resistance to corrosion ensures the longevity of the construction project. In addition, aluminum sheets are highly malleable and can be easily shaped and formed into various sizes and designs. This versatility allows architects and designers to create unique and aesthetically pleasing structures. Aluminum sheets can be used for roofing, siding, cladding, and façade systems, as well as in the construction of windows, doors, and curtain walls. Moreover, aluminum is a sustainable material, as it is 100% recyclable and requires significantly less energy to recycle compared to other metals. This makes aluminum sheets a more environmentally friendly choice for construction projects. In summary, aluminum sheets are suitable for construction applications due to their lightweight, durability, corrosion resistance, malleability, and sustainability. Their versatility and aesthetic appeal make them an excellent choice for a wide range of construction projects.

- Q: Can aluminum sheets be used for electronic enclosures?

- Yes, aluminum sheets can be used for electronic enclosures. Aluminum is a commonly used material for electronic enclosures due to its excellent properties. It is lightweight, corrosion-resistant, and provides good electromagnetic shielding. Aluminum sheets can be easily formed and fabricated into various shapes and sizes, making them suitable for housing electronic components. Furthermore, aluminum has good thermal conductivity, allowing for efficient heat dissipation from the enclosed electronics. Overall, aluminum sheets are a popular choice for electronic enclosures due to their durability, versatility, and electrical properties.

- Q: Can aluminum sheets be used for honeycomb panels?

- Yes, aluminum sheets can be used for honeycomb panels. The lightweight yet sturdy nature of aluminum makes it a popular choice for constructing honeycomb panels, which are commonly used in aerospace, automotive, and construction industries for their strength-to-weight ratio and structural integrity.

- Q: Are aluminum sheets suitable for electrical connectors?

- Yes, aluminum sheets are suitable for electrical connectors. Aluminum is a highly conductive metal, which makes it an excellent choice for transferring electric current. It has a low electrical resistance, allowing for efficient transmission of electricity. Additionally, aluminum is lightweight, corrosion-resistant, and cost-effective, making it a popular material for electrical connectors in various industries such as automotive, aerospace, and electronics. However, it is important to note that aluminum connectors may require additional measures to prevent galvanic corrosion when used with dissimilar metals.

- Q: Can aluminum sheet be used for cookware?

- Indeed, cookware can indeed employ aluminum sheets. Aluminum, being renowned for its superb heat conductivity, facilitates even heat dispersion and rapid heating. It possesses the attributes of being lightweight, long-lasting, and impervious to rust and corrosion. Moreover, aluminum cookware is reasonably priced and comparatively effortless to maintain. Nevertheless, pure aluminum proves to be a malleable metal, thus necessitating its amalgamation with other substances such as stainless steel or nonstick coatings to fortify its endurance and nonstick qualities.

Send your message to us

Thin Aluminum Sheets AA5754 for Making Aluminum Trailers - Home Depot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords