Checkered Aluminum Sheets for Roof - AA3105 for Aluminum Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Checkered Aluminium Sheets AA3105 for Making Aluminium Trailers

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Checkered Aluminium Sheets AA3105 for Making Aluminium Trailers

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Checkered Aluminium Sheets AA3105 for Making Aluminium Trailers

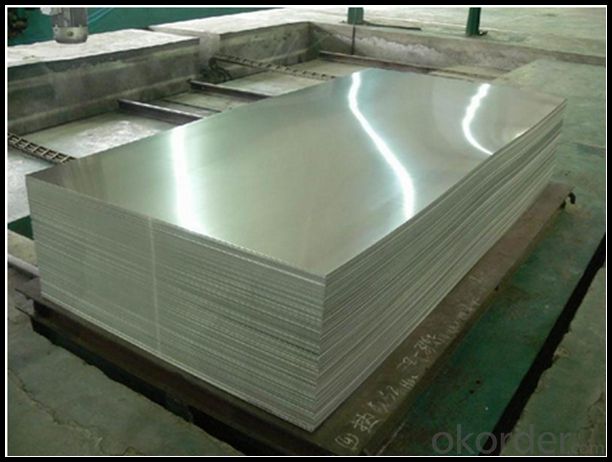

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

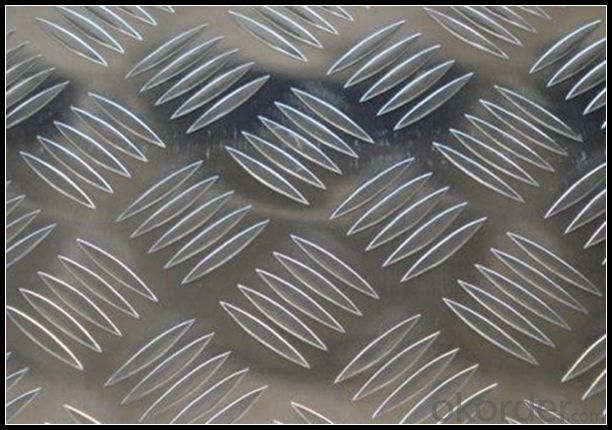

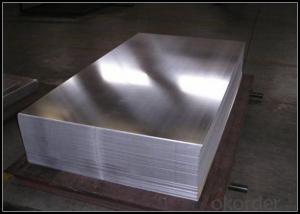

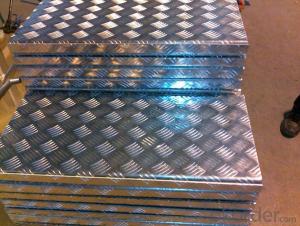

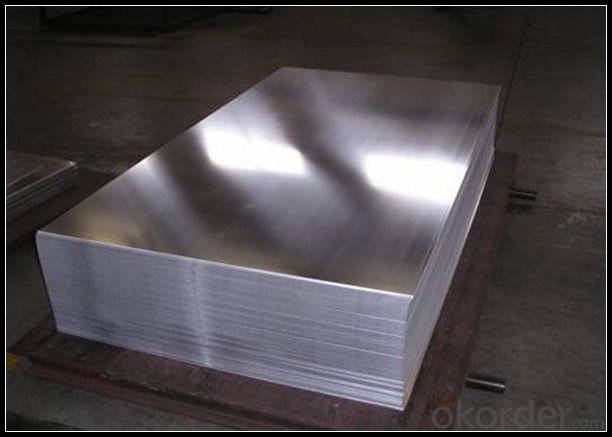

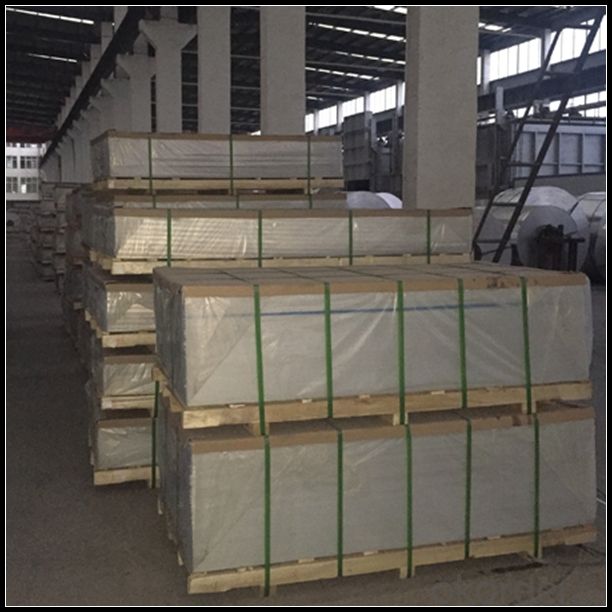

5. Image of Checkered Aluminium Sheets AA3105 for Making Aluminium Trailers

6. Package and shipping of Checkered Aluminium Sheets AA3105 for Making Aluminium Trailers

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the most effective technique for applying a coating to aluminum sheets?

- <p>The best method for coating aluminum sheets depends on the desired application and properties of the coating. Common methods include anodizing, which provides a protective oxide layer, powder coating for a durable finish, and electroplating for enhanced corrosion resistance. For decorative purposes, methods like painting or vacuum deposition can be used. Each method has its advantages and is chosen based on factors such as cost, durability, and aesthetic requirements.</p>

- Q: What are the different methods of surface treatment for aluminum sheets?

- Aluminum sheets can undergo various surface treatment methods, each with its own purpose and desired outcome. Popular methods include anodizing, chromate conversion coating, painting, and powder coating. Anodizing is commonly used to enhance the corrosion resistance and durability of aluminum sheets. This involves immersing the sheets in an electrolytic bath and applying an electric current to create a controlled oxide layer on the surface. The result is a protective and decorative coating that can be colored or sealed. Chromate conversion coating, also known as chemical conversion coating or chromating, applies a thin layer of chromate to the aluminum sheets. This method provides excellent corrosion resistance and improves paint adhesion. The coatings can be clear or have a yellowish or iridescent appearance. Painting is a widely used method to protect aluminum sheets and improve their visual appeal. Sheets are typically pre-treated with a primer to enhance adhesion, followed by the application of a topcoat for protection and color. Painted aluminum sheets come in a wide range of colors and finishes, suitable for various applications. Powder coating is an environmentally friendly and durable surface treatment for aluminum sheets. It involves electrostatically applying a dry powder onto the sheets, which is then cured in an oven. The powder melts and fuses to form a tough and attractive coating. Powder coating offers excellent resistance to corrosion, chemicals, and UV radiation. In addition to these methods, other techniques like polishing, buffing, and mechanical finishes can be employed to achieve specific desired appearances or surface qualities. Ultimately, the choice of surface treatment method for aluminum sheets depends on factors such as desired corrosion resistance, aesthetic requirements, environmental considerations, and the intended application of the sheets.

- Q: What specific considerations or precautions need to be taken into account when working with thin aluminum sheets?

- <p>When working with thin aluminum sheets, it's important to handle them carefully to prevent denting or bending. Use gloves to avoid oils and moisture from hands that can cause corrosion. Ensure proper ventilation when cutting or shaping to avoid inhaling aluminum dust. Use sharp tools to minimize the risk of tearing or marring the surface. Also, consider the specific alloy's properties, as different aluminum alloys have varying strengths and malleabilities. Always follow safety guidelines and use appropriate protective equipment.</p>

- Q: What keeps things colder- plastic wrap or aluminum foil?

- Aluminum foil. It is thicker, and metal retains heat/cold longer than the thin film of plastic would. I actually use both when I freeze things like lasagna...I use a layer of plastic wrap on it first, then a layer of foil over the top. It creates an extra (albeit fine) layer of insulation.

- Q: What are the different methods of joining aluminum sheet?

- Some of the different methods of joining aluminum sheet include welding, adhesive bonding, riveting, clinching, and mechanical fastening.

- Q: On the web page to see more information on the plating aluminum plate, I do not know what is the difference between aluminized and aluminum plating performance?

- Microstructure characteristics of hot dipped aluminized steelHot dip aluminizing steel to achieve the combination of atoms between iron and aluminum by metal bond, close together, as was shown under the microscope, from the outside to the inside with two aluminum film, three aluminum oxide layer, the alloy layer sequentially formed coating. If the coating of carbon steel, the banded structure and base metal contact.Coating thickness: if carbon steel, then the aluminum layer is 0.04-0.07mm alloy layer, the average 0.05mm. However, the thickness of each layer depends on the type of steel, the amount of carbon, and the temperature and time of the dipping. If the parent material is alloy steel, coating and the differences (omitted).

- Q: I have to repair a cracked aluminum engine block. What alumunum epoxy should I use?

- elmers glue! Lol. I believe you can have it welded. That will last for a while.or until you can get another one.

- Q: Can aluminum sheet be used for automotive body panels?

- Automotive body panels can indeed utilize aluminum sheets. In fact, aluminum is gaining popularity in the automotive industry due to its numerous advantages. Firstly, aluminum surpasses steel in terms of weight, leading to improved fuel efficiency and overall vehicle performance. Furthermore, aluminum boasts high resistance to corrosion, providing durability for body panels exposed to the elements. Additionally, aluminum exhibits remarkable formability, enabling the creation of intricate designs and enhancing design flexibility during vehicle production. Moreover, aluminum excels in absorbing crash impact, thereby enhancing vehicle safety. Nevertheless, it is important to acknowledge that utilizing aluminum for automotive body panels may necessitate specialized equipment and techniques for welding and repair purposes.

- Q: what were the cinergy field (riverfront stadium, cincinnati, oh) seats made of? were they metal or aluminum? i know they were silver under the red paint...

- Yes, they were. Aluminum IS a metal. Aluminium is a soft, durable, lightweight, ductile and malleable metal with appearance ranging from silvery to dull gray

- Q: Are the aluminum sheets suitable for manufacturing automotive chassis?

- Yes, aluminum sheets are suitable for manufacturing automotive chassis. Aluminum is a lightweight and strong material, making it an ideal choice for constructing automotive chassis. It offers several advantages such as improved fuel efficiency, better handling, and increased structural rigidity. Aluminum's ability to absorb and dissipate impact energy also enhances passenger safety. Additionally, aluminum is corrosion-resistant, which helps prolong the lifespan of the chassis. Overall, using aluminum sheets in the manufacturing process of automotive chassis provides numerous benefits and is a suitable choice for this application.

Send your message to us

Checkered Aluminum Sheets for Roof - AA3105 for Aluminum Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords