Enclosed Trailer Aluminum Sheets - Aluminium Sheet and Coil 1100 with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

hot rolled aluminium plate is sei-hard aluminium material, whose application is for construction and decoration, etc.There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

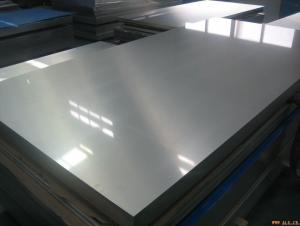

3. Image

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

- Q: What is the difference between aluminum sheet and aluminum curtain wall? The cost is high!

- Composite aluminum plate is also called aluminum plastic plate, which is composed of aluminum plastic aluminum three layers, aluminum single board is made of whole aluminum, and aluminum single board is fabricated more than aluminum plastic plate

- Q: What are the different forming techniques for aluminum sheets?

- Some of the different forming techniques for aluminum sheets include bending, stretching, deep drawing, roll forming, and hydroforming.

- Q: This question asks for methods to clean aluminum sheets to preserve their appearance.

- <p>To clean aluminum sheets and maintain their appearance, follow these steps: 1. Use a mild detergent mixed with warm water to create a cleaning solution. 2. Gently scrub the aluminum sheets with a soft cloth or sponge to avoid scratching the surface. 3. Rinse thoroughly with clean water to remove any detergent residue. 4. Dry the sheets immediately with a soft, dry cloth to prevent water spots. 5. For stubborn stains, use a non-abrasive cleaner specifically designed for aluminum. 6. Avoid using harsh chemicals or abrasive materials that can damage the aluminum's finish. Regular cleaning will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: Are aluminum sheets resistant to rust?

- Yes, aluminum sheets are highly resistant to rust. This is because aluminum naturally forms a protective oxide layer on its surface when exposed to air, which prevents further corrosion. Unlike iron or steel, which can rust when exposed to moisture and oxygen, aluminum does not require any additional coatings or treatments to protect it from rusting. This makes aluminum sheets a popular choice for a wide range of applications, including construction, automotive, and marine industries, where resistance to rust is essential.

- Q: What are the semi hard ones? What are the alloys? What are the anti rust ones, such as 3003505210606061, 7075?

- 3003: board. Strip foil. Tensile plate, tube. Extrusion tube. Type. Rod. Rod. Cold bar, cold wire, rivet wire, forging, foil, heat sink material mainly used for processing requires good molding property, high corrosion resistance, good weldability and spare parts not only have these requirements, or performance need than the workpiece of 1*** alloy with high strength, such as transportation of liquid tank and tank, pressure tank, storage device, heat exchanger, chemical equipment, aircraft fuel tank, oil pipe, reflective panels, kitchen equipment, cylinder washing machine, rivet, welding wire.3003 aluminum alloy sheet, plate, tube drawing. The extruded tube housing partition, cap, pipe3004 plate, plate, pipe extrusion tube for tensile. As long as the whole aluminum cans cans, for more than 3003 alloy parts, chemical products production and storage device, sheet processing, building baffle, cable conduit, sewer, various lighting components.3004 aluminum alloy sheet, plate mainly used for housing partition, baffle, sewer, the roof of industrial plant5052 plate, plate, sheet, foil, drawing tube, cold processing bar, cold wire, rivet wire, this alloy has good shaping property, high corrosion resistance, weldability and fatigue strength, medium static strength, used in the manufacture of aircraft fuel tank, tubing, and vehicles, sheet metal parts, ship the instrument, street lamp and rivet wire and so on.

- Q: Is it possible to utilize a custom-made door in place of a standard door within a construction or renovation project?

- <p>Yes, you can use a custom-made door to replace a standard door in your project. However, it's important to ensure that the custom door meets all the necessary building codes and specifications required for your project. This includes considerations for size, material, fire resistance, insulation, and any other relevant standards. Additionally, you should consult with your architect or contractor to confirm that the custom door will fit properly within the existing framework and align with the overall design and functionality of the space.</p>

- Q: How do i prepare the aluminium sheet to paint with oils on it?Do I have to buy special aluminium or any kind will work?

- Hi, okorder /

- Q: What types of aluminum sheets are recommended for use in cold climates?

- <p>Yes, there are specific types of aluminum sheets suitable for cold climates. These include 3003-H14 and 5052-H32 aluminum sheets. 3003-H14 is known for its excellent corrosion resistance and formability, making it ideal for cold weather applications. 5052-H32 offers high strength and good corrosion resistance, which is beneficial in extreme cold conditions. Both types can withstand low temperatures without significant loss of strength or ductility, ensuring reliability and durability in cold environments.</p>

- Q: 4.0mm five bars, aluminum plate, 4 aluminum plate, one ton, how many square?

- The price is calculated according to the price of aluminum ingot + processing fees (aluminum state), the specific price according to the size of the aluminum plate, zero shear and the whole board price also has the difference, Jiangsu Yi Heng Liu Guangxi Henan Mingtai aluminum has the.

- Q: This question asks for the steps or methods required to install aluminum sheets on a rooftop.

- <p>To install aluminum sheets on a roof, follow these steps: 1. Inspect the roof structure for any damage and ensure it can support the weight of the aluminum sheets. 2. Measure and cut the aluminum sheets to the required size using a metal saw. 3. Attach a drip edge to the eaves to prevent water from seeping under the sheets. 4. Lay the first sheet horizontally on the roof, starting from the bottom edge, and secure it with roofing nails. 5. Overlap the subsequent sheets by about 1-2 inches and fasten them with nails, ensuring a watertight seal. 6. Install flashing around vents, chimneys, and other roof projections to prevent leaks. 7. Seal all seams and fasteners with a high-quality sealant to ensure a weathertight installation. 8. Inspect the installation for any gaps or leaks and make necessary adjustments.</p>

Send your message to us

Enclosed Trailer Aluminum Sheets - Aluminium Sheet and Coil 1100 with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords