1050 and 1100 Aluminum Alloy Sheets for Railcars with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications of Aluminium Sheet

1050 and 1100 Aluminium Sheet :

1.Thickness:0.3-150mm

2.Width:500-1950mm

3.Temper: O,H12,H22,H14,H24,H16,H26,H28

Alloy | Thickness(mm) | Width(mm) | Length(mm) | Temper | DC or CC | |||||

1050,1060,1070,1100,1235 | 0.2-4.0 | 400-1850 | 500-8000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC | |||||

4.0-150 | 1000-1900 | H112,H111 | DC | |||||||

3003,3004,3105 | 0.2-4.0 | 400-1850 | 500-8000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC | |||||

4.0-150 | 1000-1900 | H112,H111 | DC | |||||||

5052,5083,5754 | 0.2-4.0 | 400-1850 | 500-8000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC | |||||

4.0-150 | 1000-1900 | H112, H111 | DC | |||||||

8011 | 0.08-0.20 | 400-1500 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18 | DC, CC | |||||

width and length:to cut as your requirement thickness:0.15-0.3m Tensile Strength:130~150MPa .Yield Strength:130-145.Elongation:≥2%,Earing Rate:≤2%.There are no stop marks or pinch marks on the surface of aluminum sheets.

There are no water stains or blisters on the surface.

The Main Features of Aluminium Sheet:

High quality with competive prices.

Wide product range of choice.

We are specific manufacture and control.

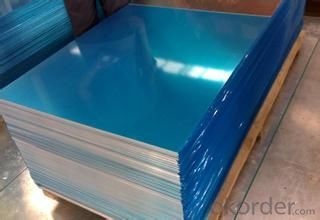

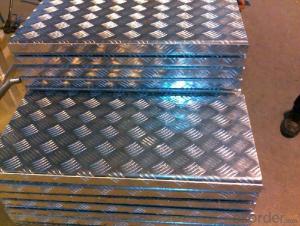

The Images of Aluminium Sheet:

FAQ:

1. Minimum Order Quantity? MOQ is 25 tons, your quantity is ok, the aluminium foil sample is available. |

2. What kind of terms of payment? T/T, L/C,D/A,D/P,Western Union are available. |

3. What grams of the product can you offer? Our products can be customized according to your requirment |

4.Can you do Customization & Reproduction if I provide a photo? Yes, we do Customization & Reproduction service, please check the details and sample above. You need to send the pictures to our email, tell us the specification you want, then we will quote you exact price. We will take photos for you check. |

5. Does the packaging safe and arrive in good conditions? Yes, Safe Packing guarrantee, all the products will arrive your door under good conditions. We response to problem of shipping if there unfortunately is. |

6. How long does it usually take to deliver the product? We'll make the shipment to you immediately. It will take about 18 to 40 days arrive worldwide. Accurate delivery time depends on the specific quantity |

7.Is drop shipping abailable? Yes, it is, we can send to worldwide. |

- Q: This question is asking for a list of different types of fasteners that can be used to attach aluminum sheets to a structure.

- <p>There are several types of fasteners used for attaching aluminum sheets to a structure, including: 1. Rivets: These are permanent fasteners that join two pieces by deforming the rivet material. 2. Screws: These are threaded fasteners that can be inserted and removed as needed. 3. Bolts: Similar to screws, bolts are used with nuts to secure aluminum sheets. 4. Adhesives: Chemical adhesives can be used for bonding aluminum sheets without visible fasteners. 5. Welding: Although not a fastener, welding can join aluminum sheets permanently. 6. Clips and Clamps: These are used for temporary or non-structural attachment. 7. Self-tapping screws: These screws create their own threads in the material being fastened. Each type has its own advantages and is chosen based on the specific requirements of the project.</p>

- Q: What are the different types of patterns available for aluminum sheets?

- Aluminum sheets come in a wide range of patterns, each with its own unique visual and functional appeal. Here are some popular patterns that you can find: 1. Diamond Pattern: This pattern features raised diamonds created by intersecting parallel lines at 60-degree angles. It offers excellent slip resistance and is commonly used for flooring, stairs, and walkways. 2. Stucco Pattern: The stucco pattern mimics the texture of traditional stucco plaster, with a pebble-like surface. It provides enhanced durability and is often used decoratively on walls, ceilings, and interior panels. 3. Hammered Pattern: The hammered pattern creates a rustic and artistic appearance with its dimpled texture. It is frequently used for decorative purposes, such as wall cladding or furniture accents. 4. Perforated Pattern: Perforated aluminum sheets have small holes that offer great ventilation and visibility. They are commonly used in architectural applications like facades, sunscreens, and noise barriers. 5. Embossed Pattern: The embossed pattern adds depth and visual interest with raised designs or patterns on the sheet's surface. It is ideal for decorative purposes, signage, and branding applications. 6. Brushed Pattern: The brushed pattern creates a sleek and modern look by giving the aluminum sheet a uniform directional grain. It is often used for architectural accents, kitchen backsplashes, and appliances. 7. Ribbed Pattern: The ribbed pattern features parallel raised ridges or lines on the sheet's surface, offering improved strength and rigidity. It is suitable for applications that require structural support or reinforcement. These examples showcase the variety of patterns available for aluminum sheets. When selecting the right pattern for a specific application, it is essential to consider the specific requirements and desired aesthetic.

- Q: Can aluminum sheets be bent?

- Indeed, the bending of aluminum sheets is possible. Aluminum, being a remarkably pliable metal, can be effortlessly manipulated and molded through methods like bending, rolling, or folding. To achieve a particular angle or curve, the procedure for bending aluminum sheets entails the application of force onto the metal. This can be accomplished using specialized equipment like a brake press or through manual techniques. The adaptability of aluminum renders it a favored option for a variety of applications in the construction, automotive, and aerospace sectors, where bending or shaping is necessary.

- Q: What are the different types of patterns available for textured aluminum sheets?

- Textured aluminum sheets offer a variety of patterns, each with its own unique visual appeal and functionality. Some commonly used patterns include: 1. Diamond pattern: Also called tread plate or checker plate, this pattern features small raised diamonds on the sheet's surface. It provides excellent slip resistance, making it ideal for applications that require traction, such as ramps, stairs, or industrial flooring. 2. Stucco pattern: Resembling a textured wall or ceiling finish, the stucco pattern has raised ridges that create a rough and bumpy surface. It is often used for decorative purposes, adding depth and visual interest to architectural elements like walls, ceilings, or furniture. 3. Hammered pattern: Mimicking the appearance of a surface hammered by hand, the hammered pattern creates a dimpled and uneven texture. It is commonly used in architectural applications, such as wall panels, backsplashes, or decorative accents, to add a rustic and artistic touch. 4. Brushed pattern: The brushed pattern is achieved by brushing the surface of the aluminum sheet with a wire brush, creating long, uniform lines. It offers a sleek and modern appearance, making it popular for applications like kitchen appliances, signage, or interior design elements. 5. Perforated pattern: Unlike the previous patterns, the perforated pattern involves creating small holes across the aluminum sheet's surface. This pattern is often used in applications that require ventilation, sound absorption, or decorative effects, such as speaker grills, filters, or façades. These examples highlight the range of patterns available for textured aluminum sheets. The choice of pattern depends on the specific project requirements, including aesthetics, functionality, and durability.

- Q: Are aluminum sheets suitable for food storage containers?

- Yes, aluminum sheets are suitable for food storage containers. Aluminum is a safe and durable material that is resistant to corrosion, making it ideal for storing and preserving food. It also has excellent heat conduction properties, allowing for even cooking and reheating.

- Q: Can aluminum sheets be bent or formed into different shapes?

- Yes, aluminum sheets can be bent or formed into different shapes. Aluminum is a highly malleable metal, which means it can be easily shaped or formed without breaking or cracking. This property makes it highly versatile for various industries and applications. Aluminum sheets can be bent, rolled, or pressed to create different shapes or forms, such as cylinders, cones, or complex geometric structures. The ability to bend or form aluminum sheets opens up a wide range of possibilities for manufacturing, construction, automotive, aerospace, and many other industries.

- Q: What is the weight per square foot of 101 aluminum sheets?

- The weight per square foot of 101 aluminum sheets can vary depending on the thickness of the sheets. Generally, the weight of aluminum is measured in pounds per square foot (lbs/ft²). To determine the exact weight per square foot of 101 aluminum sheets, you would need to know the thickness of each sheet. Once you have the thickness, you can use the density of aluminum, which is approximately 0.098 pounds per cubic inch (lbs/in³), to calculate the weight per square foot.

- Q: Can aluminum sheets be used for heat exchangers?

- Yes, aluminum sheets can be used for heat exchangers. Aluminum is widely used in heat exchangers due to its excellent thermal conductivity and corrosion resistance properties. Its lightweight nature also makes it a preferred choice for efficient heat transfer in various applications.

- Q: What is the elongation of aluminum sheets?

- The elongation of aluminum sheets refers to the amount of stretch or deformation that the sheets can undergo before breaking or tearing. It is a measure of the material's ductility or ability to be elongated without fracturing. The elongation of aluminum sheets can vary depending on factors such as the alloy composition, tempering, and processing techniques used during manufacturing. Generally, aluminum sheets have a high elongation percentage, ranging from 15% to 40%. This means that they can be bent, formed, or stretched to a certain extent without losing their structural integrity. The elongation of aluminum sheets is an important property to consider in applications where the material needs to withstand deformation or be shaped into complex forms.

- Q: What is the fatigue strength of aluminum sheets?

- The fatigue strength of aluminum sheets depends on various factors such as the alloy, thickness, and manufacturing process. Generally, aluminum alloys have good fatigue strength compared to other materials. However, the exact fatigue strength can vary significantly and must be determined through specific testing and analysis for each particular aluminum sheet.

Send your message to us

1050 and 1100 Aluminum Alloy Sheets for Railcars with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords