Aluminum Sheets for Horse Trailers - Coated Aluminium Sheet and Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Specification

ALLOY: AA1***(AA1050,AA1060,AA1070,AA1100etc)

AA3***(AA3003, AA3004,AA3005, AA3105etc)

AA5***(AA5052,AA5083,AA5754 etc)

TEMPER: H14,H16,H18,H22,H24,H26,H32,O/F

THICKNESS: O.O3mm-3.0mm

WIDTH: 30mm-1700mm

COATING: PE(POLYESTER),PVDF,EPOXY

PAINTING THICKNESS: STANDARD 16-25 MIC, MAX 40 MIC

COLOR: ACCORDING TO RAL COLORS OR CUSTOMER'S SAMPLES

STANDARD: GB/T 17748-1999

Special specification is available on customer's requirement

2.Description

In Europe aluminium experiences high rates of recycling, ranging from 42% of beverage cans, 85% of

construction materials and 95% of transport vehicles.Recycled aluminium is known as secondary aluminium, but maintains the same physical properties as primary aluminium. Secondary aluminium is produced in a wide range of formats and is employed in 80% of alloy injections. Another important use is for extrusion.

White dross from primary aluminium production and from secondary recycling operations still contains useful quantities of aluminium that can be extracted industrially.The process produces aluminium billets, together with a highly complex waste material. This waste is difficult to manage. It reacts with water, releasing a mixture of gases (including, among others, hydrogen, acetylene, and ammonia), which spontaneously ignites on contact with air;contact with damp air results in the release of copious quantities of ammonia

gas. Despite these difficulties, the waste has found use as a filler in asphalt and concrete.

3.Our advantage

We promise the best quality and price!

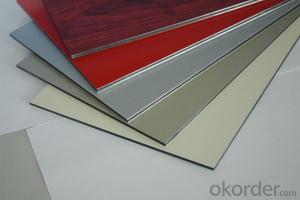

4.Pictures

5.FAQ

1)what is aluminum?

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, nonmagnetic, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface.

Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

2)What's kind of payment term we can supply?

CIF,CFR, FOB and other.

3)Can we supply samples?

Yes, we can!

- Q: Is the chemical formula for Aluminum Sulfate Al2(SO4)3?How and why is Al2(SO4)3 wrong?

- Al2(SO4)3 is right. Because SO4 is 2- And Al is 3+ So the 3 transfers to the end next to SO4 And the 2 of SO4 2- goes next to the Al So Al2(SO4)3 is right. It can also be found as an hydrate which you can read in the copy paste story of a person who also answered above. In that case it is Al2(SO4)3.xH2O and the x can be any amount of moles of water. The case wherein you talk about Al2(SO4)3 is when you have anhydrous/dry aluminiumsulphate.

- Q: HI! I have a few of my most favorite aluminum baking pans and lids that are brown with baked on grease etc...and I have not the strength or endurance to stand and buff them with a scratchy pad til they gleam....are there any cleaning chems or soaps that will do this for me?? Thanks!! Mama never told me there'd be days like this!

- Thanks, have all of the above that you mentioned...just that a few are favorites as I can pick them up easily - bad shoulders and elbows have weight bearing issues....I don't even cook all that much, but seem to burn a lot - even when boiling eggs....it is a miserable commentary on a day in the life of Aunt Susie....

- Q: Are aluminum sheets suitable for harsh weather conditions?

- Yes, aluminum sheets are highly suitable for harsh weather conditions. Aluminum is known for its exceptional corrosion resistance, making it highly durable and able to withstand extreme weather conditions such as heavy rains, snow, and strong winds. Additionally, aluminum sheets are lightweight yet robust, which allows them to resist damage from impacts or hailstorms. These properties make aluminum sheets a popular choice for outdoor applications, including roofing, cladding, and siding, as they provide long-lasting protection even in challenging weather environments.

- Q: Is it suitable to use aluminum windows in areas with cold weather conditions?

- <p>Yes, you can use aluminum windows in cold climates, but there are considerations. Aluminum is a good conductor of heat, which can lead to heat loss in cold weather. To mitigate this, insulated glass units and thermally broken frames can be used. These designs slow down heat transfer, making aluminum windows more energy-efficient in cold climates. Additionally, proper sealing and weatherstripping are crucial to prevent drafts and ensure the windows perform well in low temperatures.</p>

- Q: I can't seem to find what uses or contains Aluminum Nitride. Help!

- Don't know where you looked, but this came up with very basic web search. Metallization methods are available to allow Aluminium nitride to be used in electronics applications similar to those of alumina and beryllium oxide. Among the applications of Aluminium nitride are opto-electronics, dielectric layers in optical storage media, electronic substrates, chip carriers where high thermal conductivity is essential, military applications, as a crucible to grow crystals of gallium arsenide, steel and semiconductor manufacturing. Epitaxially grown thin film crystalline aluminium nitride is also used for surface acoustic wave sensors (SAW's) deposited on silicon wafers because of the Aluminium nitride's piezoelectric properties. One application is an RF filter used in mobile phones called a thin film bulk acoustic resonator (FBAR). This is a MEMS device that uses aluminium nitride sandwiched between two metal layers.

- Q: This question asks for a comparison between the benefits and drawbacks of utilizing products made from recycled aluminum.

- <p>Advantages of using recycled aluminum products include reduced energy consumption, lower greenhouse gas emissions, and a decrease in the need for raw material extraction. It also promotes waste reduction and supports a circular economy. Disadvantages might include potential quality concerns, as recycled aluminum might not always meet the same strength and durability standards as new aluminum. Additionally, there can be higher initial costs associated with recycling processes and the need for advanced sorting and processing technologies.</p>

- Q: Can aluminum sheets be used for sound insulation?

- Aluminum sheets possess a certain degree of effectiveness in sound insulation. Although aluminum is not as proficient in soundproofing as materials such as rubber or foam, it can still offer a certain level of sound insulation if utilized appropriately. One can employ aluminum sheets as a barrier or partition in walls, ceilings, floors, or other surfaces to decrease the transmission of sound waves. Nevertheless, it is noteworthy to mention that attaining optimal outcomes might require the inclusion of supplementary soundproofing materials or techniques.

- Q: Can aluminum sheets be used for elevator panels?

- Yes, aluminum sheets can be used for elevator panels.

- Q: What is the cost of an aluminum sheet?

- The price of an aluminum sheet can change due to various factors, including thickness, size, grade, and market conditions. Typically, aluminum sheets are priced based on square footage or weight. On average, the price can vary from $0.50 to $5 per square foot or $1 to $10 per pound. It is crucial to understand that these figures are approximate and subject to change based on factors such as supply and demand, location, and others. To obtain an accurate cost, it is advisable to reach out to local suppliers or explore online marketplaces for the latest pricing information.

- Q: Are aluminum sheets suitable for aircraft panels?

- Yes, aluminum sheets are suitable for aircraft panels. Aluminum is widely used in the aviation industry due to its excellent strength-to-weight ratio, which makes it ideal for constructing lightweight yet strong aircraft structures. Aluminum sheets are commonly used for aircraft panels because they offer a combination of durability, corrosion resistance, and ease of fabrication. Additionally, aluminum can be easily formed and welded, allowing for complex panel shapes to be created. Furthermore, aluminum has good electrical conductivity, which is important for the proper functioning of various aircraft systems. Overall, the use of aluminum sheets for aircraft panels helps to ensure the structural integrity and performance of the aircraft.

Send your message to us

Aluminum Sheets for Horse Trailers - Coated Aluminium Sheet and Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords