Aluminum Sheets Idaho - Aluminium Sheet and Aluminum Slabs Stocks with Best Price

- Loading Port:

- Shanghai

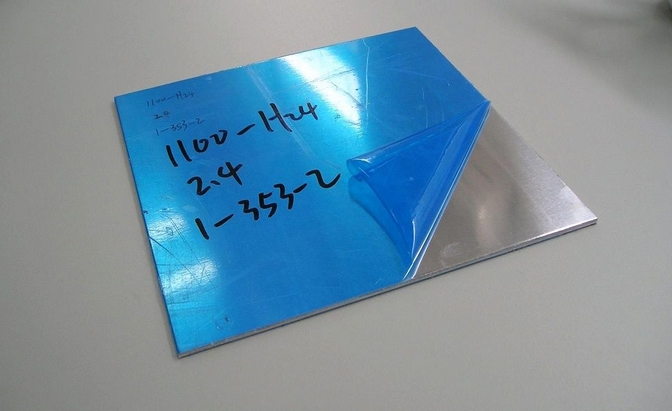

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Can aluminum sheet be used for food contact applications?

- Yes, aluminum sheet can be used for food contact applications. Aluminum is a safe and commonly used material for food packaging and cooking utensils due to its non-toxic properties, resistance to corrosion, and ability to maintain food quality and freshness.

- Q: It is a club aluminium dutch oven from the 50's. It is discolored on the interior and has baked on dirt on the exterior. The exterior has a textured surface which makes cleaning more difficult. I tried baking soda and water paste, but it did not budge it!

- I have an aluminum double boiler.. that I only used for making pie pudding and yes, it got yucky. I found something and I cleaned it and i was so proud of myself but that was a while ago and it am racking my brain to remember. If I recall, I'll try to get back to you and let you know, but for now, I think it was the using CLR cleaner. Good luck. And if they say not to use it... I'd say it was time to update. Clean it... for display or sale to collectors.

- Q: I'm working on a costume that's entirely made of cardboard (it's a giant robot), and I was wondering What's the best way to1 turn Soda cans into aluminum sheeting2: attach the aluminum everywhere on the robot3. Attach the aluminum to the aluminumThank you in advance.

- Why not heavy duty aluminum foil glued to cardboard? that would look a lot better than patched up pieces of aluminum from tin cans. How would you connect the chunks of aluminum together? and remove the label. Note that soda cans have a coating of plastic on the inside. I don't see any easy way to attach the bits of aluminum from tin cans together, and remove the painted on labels. It would look just like that, pieces of cans glued together. In stead of cardboard you could use foam board which is lighter and more rigid.

- Q: Can aluminum sheet be used for electrical enclosures?

- Indeed, electrical enclosures can indeed utilize aluminum sheet. The remarkable conductivity, lightweight composition, and resistance to corrosion render aluminum a favored option for electrical enclosures. It effectively safeguards against electromagnetic interference and possesses commendable heat dissipation properties. Moreover, aluminum boasts malleability, enabling the production of intricate shapes and designs. In summary, aluminum sheet is a fitting material for electrical enclosures and finds widespread application in diverse industries like electronics, telecommunications, and power distribution.

- Q: Is aluminum sheet fire-resistant?

- Aluminum sheet is not inherently fire-resistant, but it does have certain properties that make it more fire-resistant than other materials. Aluminum has a high melting point, which means it can withstand high temperatures without melting or catching fire. Additionally, aluminum has a low thermal conductivity, meaning it does not easily transfer heat. This makes it more difficult for fire to spread across an aluminum sheet. However, it is important to note that aluminum can still be affected by fire. When exposed to extreme heat, aluminum can weaken and lose its structural integrity. It can also become more susceptible to burning if exposed to certain chemicals or intense flames. To enhance the fire resistance of aluminum sheet, it can be coated with fire-retardant materials or treated with fire-resistant coatings. These additional measures can help to further reduce the risk of fire and improve the overall fire performance of the aluminum sheet. In summary, while aluminum sheet is not completely fire-resistant, it does possess certain characteristics that make it more resistant to fire than other materials. However, it is crucial to take appropriate precautions and use additional fire-resistant treatments when necessary to ensure maximum safety.

- Q: What specific considerations should be taken into account when using aluminum sheets in cold weather conditions?

- <p>In cold climates, aluminum sheets should be selected with consideration for their thermal expansion properties. It's important to use alloys with low thermal expansion coefficients to minimize distortion. Additionally, the design should account for potential contraction and expansion to prevent warping or cracking. Proper insulation and sealing are crucial to prevent condensation and moisture buildup, which can lead to corrosion. It's also advisable to use thicker sheets to enhance durability and resistance to the elements. Regular inspections and maintenance are recommended to ensure the longevity of aluminum structures in cold environments.</p>

- Q: Are 101 aluminum sheets suitable for high-temperature applications?

- No, 101 aluminum sheets are not suitable for high-temperature applications. 101 aluminum is a pure aluminum alloy with excellent corrosion resistance and good formability, but it has a low melting point of 660 degrees Celsius (1220 degrees Fahrenheit). High-temperature applications typically require materials with higher melting points and better heat resistance, such as stainless steel or high-temperature alloys. Using 101 aluminum sheets in high-temperature environments could result in deformation, melting, or failure of the material, which could compromise the integrity and safety of the application.

- Q: How are aluminum sheets cut or shaped?

- Depending on the desired outcome, various methods can be employed to cut or shape aluminum sheets. One commonly used technique involves the utilization of a saw, such as a circular saw or a bandsaw, equipped with a carbide-tipped blade specially designed for cutting metal. This allows for the creation of straight cuts and can be employed for both thin and thick aluminum sheets. Another approach entails the use of a shear, which is a machine equipped with sharp blades to effectively cut the aluminum sheet. Shearing is particularly advantageous when it comes to swiftly and efficiently cutting straight lines, especially for thinner sheets. For more intricate shapes or curves, aluminum sheets can be cut using either a water jet cutter or a laser cutter. Water jet cutting involves the usage of a high-pressure jet of water mixed with an abrasive substance to effectively cut through the sheet. On the other hand, laser cutting employs a focused laser beam to melt or vaporize the aluminum, resulting in precise and intricate cuts. In addition to cutting, aluminum sheets can also be shaped through processes like bending, rolling, or stamping. Bending necessitates the use of a press brake to bend the sheet into the desired angle or shape. Conversely, rolling involves employing a rolling machine to gradually shape the sheet into curves or cylinders. Lastly, stamping encompasses pressing the sheet against a die to create specific shapes or patterns. Ultimately, the choice of method for cutting or shaping aluminum sheets depends on factors such as the sheet's thickness, the desired outcome, and the availability of equipment.

- Q: Can aluminum sheets be laminated with other materials?

- Yes, aluminum sheets can be laminated with other materials. Lamination involves bonding different layers together to create a composite material with enhanced properties and functionality. Aluminum sheets can be laminated with various materials such as polymers, fabrics, or other metals to improve their strength, durability, insulation, or aesthetic appearance. This process allows for the customization and optimization of aluminum sheets for specific applications.

- Q: Are aluminum sheets suitable for automotive suspension components?

- Automotive suspension components can indeed be made from aluminum sheets, which offer numerous advantages. Firstly, aluminum sheets are much lighter than traditional steel components. This reduction in weight can lead to improved fuel efficiency and overall vehicle performance. By reducing the weight of suspension components, the vehicle's handling, acceleration, and braking can be enhanced, resulting in a smoother and more responsive ride. Secondly, aluminum possesses an excellent strength-to-weight ratio. This means that it can provide the necessary structural integrity and support for suspension components while still being lightweight. It has high tensile strength and stiffness, enabling it to withstand the stresses and forces exerted on suspension components during normal driving conditions. Furthermore, aluminum is highly resistant to corrosion, which is especially beneficial for automotive suspension components that are exposed to various environmental conditions. This corrosion resistance ensures the longevity and durability of the suspension system, reducing the need for frequent repairs or replacements. Moreover, aluminum is easily machinable, allowing for the creation of complex and intricate designs that can optimize suspension performance. Its flexibility in shaping and forming enables manufacturers to create suspension components with specific geometries and characteristics to meet the desired performance requirements. In conclusion, aluminum sheets are an excellent choice for automotive suspension components due to their lightweight nature, high strength-to-weight ratio, corrosion resistance, and machinability. These properties make aluminum a preferred material for suspension components, resulting in improved vehicle performance, fuel efficiency, and overall durability.

Send your message to us

Aluminum Sheets Idaho - Aluminium Sheet and Aluminum Slabs Stocks with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords