Aluminum Sheets for Sale Kansas - Best Stocked Aluminum Sheets at Warehouse Prices

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

aluminum shees with cold rolled and hot rolled plate are widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 8000series, 7000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1100,3003, 3005, 3105, etc.

The temper is include H14, H22, H24, H44,O,H114,etc.

2. Main features of the product

a.Competitive price

b. Shortest service.

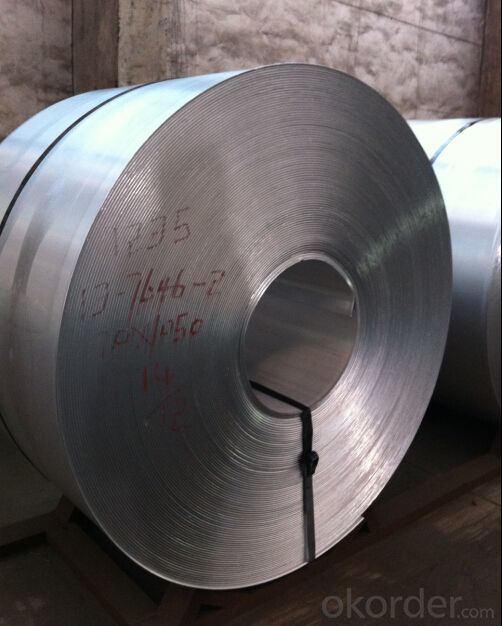

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1000mm*2500mm,1250mm*2500mm,at random sizes,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 7 tons/each size.

How many tons did you export in one year

USA, Japan,UAE, Vietnam, Canada, etc.

What is your mainly products?

---Normally they are checkered aluminum sheet with big-5-bar and small-5-bar pattern,mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Does anyone know how to polish aluminum on a motorcycle that isn't too expensive to do?

- Get a $5 can of metal polish and a rag or get you one of those things that fits a drill with the really soft cloth wheel on it and polish till your hearts content. I have done the side covers, manifolds, even the carbs on old british bikes.

- Q: Are aluminum sheets suitable for interior design applications?

- Aluminum sheets are an excellent choice for interior design purposes. This material is both versatile and durable, allowing for various creative uses in enhancing the aesthetics of indoor spaces. Its malleability enables easy shaping, cutting, and manipulation, resulting in unique and contemporary designs. Different finishes, such as brushed, polished, or textured, further expand the design options. One major advantage of utilizing aluminum sheets in interior design is their lightweight composition. This feature simplifies handling and installation, reducing labor and transportation expenses. Additionally, aluminum's corrosion resistance makes it perfect for environments with high humidity or moisture, such as bathrooms or kitchens. Aluminum sheets find application in various aspects of interior design, including wall cladding, ceiling panels, room dividers, furniture, and decorative elements. The ability to paint or coat them in different colors allows seamless integration into any design scheme. Furthermore, perforation or engraving can create patterns or intricate designs, adding a distinct visual appeal to the space. Moreover, aluminum is a sustainable material with high recyclability. The recycling process consumes significantly less energy compared to the production of new aluminum, making it an environmentally friendly option for interior design applications. To summarize, the versatility, durability, lightweight nature, corrosion resistance, and manipulability of aluminum sheets make them highly suitable for interior design. They offer numerous design possibilities and can be used in various applications, rendering them a popular choice among designers and architects.

- Q: Can aluminum sheets be embossed or engraved?

- Yes, aluminum sheets can be embossed or engraved. Embossing involves creating a raised design or pattern on the surface of the aluminum sheet, while engraving involves cutting or etching a design into the surface. Both techniques can be used to add decorative or functional elements to aluminum sheets. Embossed or engraved aluminum sheets are commonly used in various industries including automotive, aerospace, signage, and architectural applications. The process of embossing or engraving aluminum sheets typically involves using specialized machinery or tools to create the desired design.

- Q: which has more volume? a kg of gold or a kg of aluminum? please explain in physics terms

- Think of it this way: Which metal is lighter? How do you know this? Because a given volume of gold weighs more than a given volume of aluminum. So which one has more volume? A kg of aluminum.

- Q: I'm gonna drop the dime and get a bass boat. other than weight why is a fiberglass better than aluminum?I'm looking at the difference between the top of the line BassTracker and the bottom of the line Nitro. I only want about a 90 -115 hp and I'm gonna buy a couple years old to save some money.. so what are the pros - cons?

- This Site Might Help You. RE: aluminum boat vs fiberglass? I'm gonna drop the dime and get a bass boat. other than weight why is a fiberglass better than aluminum? I'm looking at the difference between the top of the line BassTracker and the bottom of the line Nitro. I only want about a 90 -115 hp and I'm gonna buy a couple years old to save...

- Q: Some say you should use the 'dull' side of aluminum foil when cooking etc. There's something potentially bad about the shiny side.True or not?

- Straight from Reynolds: Which side of Reynolds Wrap? Aluminum Foil should I use, the shiny or the dull side? Actually, it makes no difference which side of the aluminum foil you use—both sides do the same fine job of cooking, freezing and storing food. The difference in appearance between dull and shiny is due to the foil manufacturing process. In the final rolling step, two layers of foil are passed through the rolling mill at the same time. The side coming in contact with the mill's highly polished steel rollers becomes shiny. The other side, not coming in contact with the heavy rollers, comes out with a dull or matte finish. The exception is when using Reynolds Wrap? Release? Non-Stick Aluminum Foil. The non-stick coating is applied during manufacturing to the dull side of the foil. Always place the non-stick (dull) side toward the food.

- Q: What kind of paint should be sprayed on the aluminium board?

- Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.

- Q: How do I clean and maintain aluminum sheets?

- To clean and maintain aluminum sheets, there are a few steps you can follow: 1. Start by preparing a cleaning solution. Mix a mild detergent or dish soap with warm water in a bucket or sink. Avoid using harsh chemicals or abrasive cleaners as they can damage the aluminum. 2. Dip a soft sponge or cloth into the cleaning solution and gently scrub the surface of the aluminum sheets. Make sure to cover the entire surface, paying extra attention to any stains or dirt buildup. 3. If there are stubborn stains or grime, you can use a non-abrasive brush or a toothbrush to scrub the affected areas. Be careful not to apply too much pressure, as this can scratch the aluminum. 4. Rinse the sheets thoroughly with clean water to remove any residue from the cleaning solution. Ensure that all soap is fully rinsed off. 5. After rinsing, use a clean, dry cloth to wipe off any excess water and dry the aluminum sheets. This helps prevent water spots or stains from forming. 6. To maintain the shine and condition of the aluminum, you can apply a thin layer of aluminum polish or wax. Follow the instructions provided by the manufacturer for the best results. 7. Regularly inspect the aluminum sheets for any signs of damage, such as dents, scratches, or corrosion. If you notice any issues, address them promptly to prevent further damage. Remember, it is essential to handle aluminum sheets with care to avoid any damage. Avoid using abrasive materials, sharp objects, or harsh chemicals that can scratch or corrode the surface. Regular cleaning and maintenance will help keep your aluminum sheets looking their best and extend their lifespan.

- Q: I know 7005 series aluminum is stronger and lighter than 6061series, but how does 7005 compare to 2014 series?

- i okorder

- Q: Can the aluminum sheets be used for manufacturing decorative trim?

- Yes, aluminum sheets can be used for manufacturing decorative trim. Aluminum is a versatile material that is lightweight, durable, and resistant to corrosion. It can be easily shaped and formed into various decorative designs and patterns. Additionally, aluminum can be coated or painted in different colors to enhance its aesthetic appeal. Therefore, aluminum sheets are a popular choice for manufacturing decorative trim in various industries, including architecture, automotive, and interior design.

Send your message to us

Aluminum Sheets for Sale Kansas - Best Stocked Aluminum Sheets at Warehouse Prices

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords