8 1 2 X 11 Sheets Aluminum for Ink Jet - Aluminium Sheet 1050 1060 1100 3003 with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.2~320mm |

Width | <2800mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Payment | L/C ,T/T |

Brief Introduction for Cold Rolled Steel Coil

Cold Rolled Steel Coil is steel that has been worked below its recrystallization temperature by passing it between a pair of rollers. Recrystallization temperature is the temperature at which grains in the lattice structure of the metal have been rearranged, leaving it free of strain and deformations. Cold Rolled Steel Coil is pre-treated before being cold rolled with a process known as pickling, which uses strong acids to remove scale and other impurities. The Cold Rolled Steel Coil is then passed through rollers to reduce its thickness. Most cold rolling takes place in multiple passes and as the size of the Cold Rolled Steel Coil is further reduced, its strength and hardness both increase, but its ductility decreases. After cold rolling, heating the metal up in a process known as annealing can restore some of its ductility. The final Cold Rolled Steel Coil may be manufactured in the form of sheets, strips, bars, or other forms.

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

Our Services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3. We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

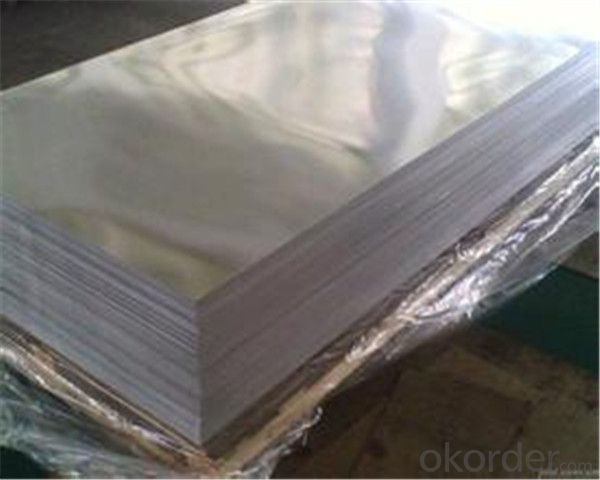

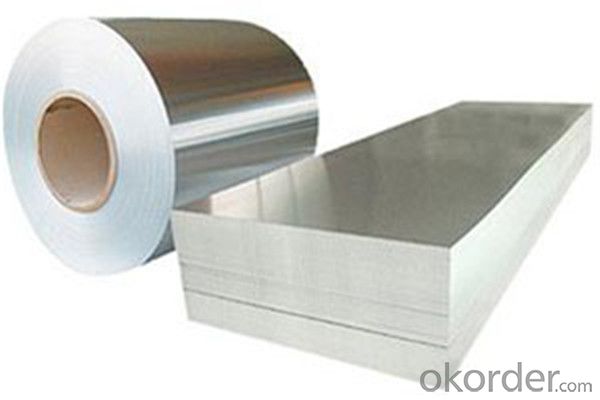

Photos of products

If you were to take a quick look around the room you're currently sitting in, it's likely that you would be able to name a number of objects that have been made using aluminium. This metal is one of the most popular on earth and, as such, it has a number of applications that feature in our daily lives. One of the best applications for aluminium today is as a roofing material, and here are the reasons why:

Leaks

This is something that all homeowners would like to avoid at all costs, as leaks can cause considerable damage to the structural integrity of a building, not to mention ruin paint jobs and carpet. Fortunately, aluminium roofing can be installed at varying pitches whilst still providing adequate water run off. The next time there's a torrential downpour, you won't have to fear flooding.

Flammable

Another concern for homeowners is how their property will be able to withstand a fire, should one ever break out. This is an area in which aluminium roofing is truly given the chance to shine. Unlike other roofing materials, this metal is not flammable in the slightest and will not be coated with substances that could catch fire. This makes aluminium an extremely safe choice.

Cost

Whilst there are some arguments that suggest aluminium roofing costs more than most other types, you cannot deny the benefits that such a choice will provide your home with. Even so, purchasing sheets of corrugated aluminium can actually work out to be a very cost effective way of providing your home and possessions with protection.

Lightweight

The need to repair or replaced sections of the roof can strike fear into the hearts of many homeowners, simply for the fact that they dread having to haul a bunch of tiles up the side of the house. With aluminium roofing, on the other hand, you will be able to handle the sheets much easier and won't risk falling off the roof simply getting them up there.

With all of the advantages offered to you and your home with the inclusion of aluminium roofing, it's any wonder that more buildings haven't been fitted with this fantastic material. If you are in the process of renovating or building your home and have been on the lookout for a suitable roofing material, you really should be looking into aluminium for the fact that is lessens the chances of leaks and is not flammable.

- Q: What does aluminum plate mean?

- Dear, 1070 and 1060 are not the specifications of aluminum sheet, but the type of aluminum plateThe model is used to distinguish the different components of aluminum, the model is different, the composition of aluminum is differentShenzhen Cheng Cheng metal - - - --- aluminum plate - -

- Q: This question asks for methods to preserve the aesthetic quality of aluminum sheets and prevent deterioration over time.

- <p>To maintain the appearance of aluminum sheets over time, follow these steps: 1. Regularly clean the sheets with a mild detergent and water to remove dirt and grime. 2. Avoid using harsh chemicals or abrasive materials that can scratch the surface. 3. Apply a protective coating or sealant if the sheets are exposed to harsh weather conditions or corrosive environments. 4. Inspect the sheets periodically for signs of corrosion or damage and address any issues promptly. 5. Keep the aluminum sheets dry, as moisture can lead to rust and other forms of deterioration. Proper maintenance will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: Can someone please help me with the resonance structure for AlCl3. When I draw it, the central Al does not have a complete octet. I read that this is usually the case for atoms like Boron and Aluminium who only have three valence electrons. Is this correct? Also, as a follow on question, does AlCl3 display resonance?

- I'll do NO2- as an example. The Lewis structure is O=N-O with two electron pairs on the left O and 3 electron pairs on the right O and one electron pair on the N. But you could also draw it as O-N=O. So, those are the two resonance structures. The actual is where N has 1.5 bonds to each O on average.

- Q: 6061 what is the density of the aluminum plate?

- 6061 aluminum plate density:6061 aluminum plate is aluminum alloy, the density is calculated according to 2.9g/cm3.Calculation method:Aluminium plate weight (kg) =0.0000029 * * * * width * lengthAluminium tube weight (kg) =0.0000029 * wall thickness * (outside diameter wall thickness) * lengthFormula for weight calculation of aluminium bars (kg) =0.0000029 * radius * radius * length

- Q: How do I choose the right thickness for my aluminum sheet?

- When deciding on the appropriate thickness for your aluminum sheet, there are several factors that should be taken into account. To begin with, it is essential to determine the intended use or purpose of the aluminum sheet. Different projects may necessitate varying thicknesses depending on their structural or aesthetic requirements. For example, if the aluminum sheets are intended for roofing or siding applications, a thicker gauge may be necessary to ensure sufficient durability and resistance to weather conditions. Moreover, the level of strength and rigidity required should be considered. Thicker aluminum sheets generally offer greater strength and stability, which is especially important for applications like construction or automotive components. However, it is important to bear in mind that thicker sheets may also be heavier and more challenging to work with, so the practicality and weight limitations of your project should be taken into consideration. Additionally, the size of the aluminum sheet needed should be thought about. Larger sheets may require thicker gauges in order to maintain their structural integrity, whereas smaller sheets may not require as much thickness. Lastly, your budget should be factored in. Thicker aluminum sheets can be more expensive due to increased material costs and the manufacturing process. It is advisable to strike a balance between the required thickness and your budget constraints to ensure a cost-effective decision. To summarize, selecting the appropriate thickness for your aluminum sheet involves considering the specific application, required strength, size, and budget. It is recommended to seek guidance and advice from industry experts or suppliers who can provide tailored recommendations based on your specific needs.

- Q: Can aluminum sheets be used for food processing conveyors?

- Yes, aluminum sheets can be used for food processing conveyors. Aluminum is a lightweight, durable, and corrosion-resistant material that is often preferred in the food industry due to its hygienic properties. It is commonly used for making conveyor belts and other equipment in food processing facilities.

- Q: What are the different methods of surface embossing aluminum sheets?

- There are various methods of surface embossing aluminum sheets, including mechanical embossing, chemical embossing, and hydraulic embossing. Mechanical embossing involves using a patterned roller or press to create raised or recessed designs on the sheet's surface. Chemical embossing utilizes chemical etching or acid treatments to selectively remove material and create patterns. Hydraulic embossing employs hydraulic presses to create deep and intricate designs on the aluminum sheet. These methods offer different options for achieving desired textures and patterns on aluminum surfaces.

- Q: Does aluminum sheet require special handling during transportation?

- Transporting aluminum sheets requires special handling due to their lightweight nature and susceptibility to damage if mishandled. To prevent scratching, bending, or denting, it is necessary to take specific precautions. Packaging and securing the sheets in a manner that restricts movement and offers sufficient protection against impacts is crucial. Furthermore, it is important to transport aluminum sheets separately from heavy objects or materials to avoid potential damage caused by their weight. In conclusion, ensuring the safe transportation of aluminum sheets necessitates giving them special care and attention.

- Q: What are the properties of anodized aluminum sheets?

- Anodized aluminum sheets are highly desirable for a variety of applications due to their distinct properties. Firstly, they possess a protective oxide layer on their surface, which enhances their resistance to corrosion. This layer is formed through an electrochemical process called anodization, wherein the aluminum sheet is treated with an electric current in an acid electrolyte solution. Consequently, anodized aluminum sheets become more durable and capable of withstanding harsh environments, making them suitable for outdoor use. Another notable property of anodized aluminum sheets is their improved scratch resistance. Through the anodization process, not only is a protective layer created, but the surface of the aluminum also becomes hardened, rendering it more resistant to scratches and wear. This property proves particularly advantageous in applications where frequent handling or abrasive conditions are involved. Moreover, anodized aluminum sheets can be manufactured in a wide range of colors. The anodization process enables the integration of dyes or pigments into the oxide layer, resulting in an array of vibrant color options. This aspect makes anodized aluminum sheets highly popular in architectural and decorative applications, as they can be customized to meet specific design requirements. Additionally, anodized aluminum sheets possess excellent thermal and electrical conductivity. The process of anodization does not significantly impact these inherent properties of aluminum. Consequently, anodized aluminum sheets can efficiently dissipate heat and conduct electricity, making them well-suited for applications such as heat sinks, electronic enclosures, and electrical components. To sum up, anodized aluminum sheets possess enhanced corrosion resistance, improved scratch resistance, a wide range of color options, and excellent thermal and electrical conductivity. These properties render anodized aluminum sheets a versatile and durable material for various industries and applications.

- Q: Are aluminum sheets suitable for insulation purposes?

- Indeed, aluminum sheets prove to be well-suited for insulation endeavors. Aluminum, being a notably reflective substance, possesses the ability to effectively impede the transmission of heat, rendering it a superb selection for insulation purposes. With its low emissivity value, aluminum reflects heat radiation rather than absorbing it, thereby aiding in the preservation of a uniform temperature within a given area and diminishing the necessity for heating or cooling. Moreover, aluminum sheets are characterized by their lightweight nature, straightforward installation process, and resistance to moisture, making them an eminently practical choice for insulation in a plethora of applications, including attics, walls, floors, and HVAC systems.

Send your message to us

8 1 2 X 11 Sheets Aluminum for Ink Jet - Aluminium Sheet 1050 1060 1100 3003 with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords