Mill Finished Aluminum Profiles for LED Strips 8xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

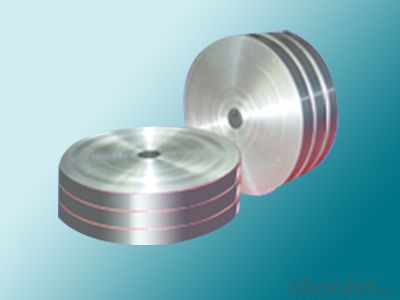

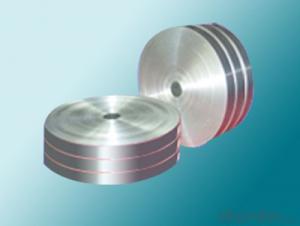

aluminum strips for transformer

alloy: 1050/1060 3003/8011

Thickness range: 0.15 to 0.6mm

Surface finish: washed by chemical water

Bright and smooth surface, without flow lines

Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set

aluminum coil/strip for PEX-AL-PEX pipedata:

| Dimension(MM) | 0.20*49*C; 0.23*61.7*C 0.28*77*C; 0.35*99*C | Alloy and Temper | 8011 0 | Product | aluminum coil/strip | ||||||

| Techuique Standard | YS/T 434-2000 | ||||||||||

| Chemical Composition(%) | |||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other | Al ≥ | ||

| | |||||||||||

| 0.50~0.9 | 0.6~1.0 | 0.1 | 0.2 | 0.05 | 0.05 | 0.1 | 0.08 | - | remainder | ||

| | |||||||||||

| Notice: Aluminum foil not contains Pb,As and other Virose elements. | |||||||||||

| Mechanical Property | |||||||||||

| Temper | THICKNESS | Strength(Mpa) | Elongation(%) | | |||||||

| 0 | 0.20mm; 0.23mm; 0.28mm; 0.35mm | 100~120 | 20% | | |||||||

Advantage:

1. Good quality,low price.

2. Short delivery time

3. Welding: Not allowed

4. Windings: No excessive run out of windings

5. Form of winding on coil:No ovalisation allowed

6. Camber: Aiming value ≤ 1mm/2.5m, Demand ≤ 2mm/2m

7. No Bur on Side edge

8. No wave on side

9. No oil stains,no wrinkle, on surface

10. Corrosion Resistant

- Q: Describe the steps involved in the production of aluminum strips from raw materials to the final product.

- <p>The process of manufacturing aluminum strips involves several key steps. Initially, raw materials, typically bauxite ore, are mined and then processed to extract alumina (aluminum oxide). This alumina is then dissolved in a cryolite bath at high temperatures within a reduction cell in the Hall-H茅roult process. Here, aluminum is reduced and collected as molten metal. The molten aluminum is then cast into ingots or directly into billets. These billets are then hot or cold rolled into strips, with multiple passes through rollers to achieve the desired thickness and width. The strips may undergo annealing to restore ductility and improve workability. Finally, the aluminum strips are cleaned, coated if necessary, and then cut to length, inspected, and packaged for distribution.</p>

- Q: This question asks for a list of various types of aluminum components used in the automotive industry.

- <p>Aluminum is widely used in the automotive industry due to its lightweight and high strength. Different types of automotive aluminum parts include engine components such as cylinder heads and blocks, transmission housings, suspension parts like control arms and knuckles, wheels and rims, body panels, and doors. Other applications include heat exchangers, radiators, and various brackets and structural components. The use of aluminum can significantly reduce the weight of vehicles, improving fuel efficiency and performance.</p>

- Q: What distinguishes extruded aluminum strips from rolled ones in terms of manufacturing process and properties?

- <p>Extruded aluminum strips are formed by forcing aluminum through a die, creating a specific profile or shape. This process results in a more uniform cross-section and can produce complex profiles. Extruded strips are stronger and have better dimensional stability due to the grain flow being aligned with the direction of the extrusion. Rolled aluminum strips, on the other hand, are created by passing aluminum between rollers to achieve the desired thickness and width. This method is more suitable for producing thin, wide strips and is less costly for simpler profiles. Rolled strips may have some residual stresses and are not as strong as extruded ones, but they are more flexible and can be used in applications requiring formability.</p>

- Q: The question asks if it's possible to use various adhesives or fasteners for installing different kinds of aluminum strips.

- <p>Yes, you can use different types of adhesives or fasteners to install different types of aluminum strips. The choice depends on the application, the weight of the strip, and the surface it's being attached to. For lightweight strips and smooth surfaces, adhesives like double-sided tape or construction adhesive can be effective. For heavier strips or where a more permanent solution is needed, mechanical fasteners such as screws or rivets might be more appropriate. Always consider the strip's weight, the surface material, and the desired longevity of the installation when selecting the type of adhesive or fastener.</p>

- Q: What are the environmentally friendly options for aluminum strips?

- <p>Yes, there are environmentally friendly types of aluminum strips. Recycled aluminum strips are more eco-friendly as they require significantly less energy to produce compared to virgin aluminum. Additionally, using aluminum strips with a high recycled content reduces waste and conserves natural resources. Another option is to look for aluminum strips that are produced using renewable energy sources, which further reduces their carbon footprint. Lastly, choosing aluminum strips with a lower coating or treatment that is biodegradable or has a lower environmental impact can also contribute to their environmental friendliness.</p>

- Q: What is the difference between cold rolling and hot rolling of aluminium plate and aluminium strip? Which kind of aluminum plate is good? Speak a little more popularly

- The aluminum plate and the aluminum band are better understood. One is the plate and the other is the coil.

- Q: Is it possible to utilize aluminum strips in outdoor settings?

- <p>Yes, aluminum strips can be used in outdoor applications. They are known for their corrosion resistance and durability, making them suitable for various outdoor uses. Aluminum's resistance to weathering and its ability to withstand temperature fluctuations without significant degradation make it an ideal material for outdoor construction, signage, and decorative purposes. However, it's important to consider the specific environmental conditions and protective coatings or treatments that may be necessary to prolong the life and performance of aluminum strips in outdoor settings.</p>

- Q: Is it possible to apply paint to aluminum strips once they have been installed?

- <p>Yes, aluminum strips can be painted after installation. However, it is essential to prepare the surface properly. This includes cleaning the aluminum to remove any dirt or grease, then lightly sanding it to create a better surface for the paint to adhere to. It is also recommended to use a primer specifically designed for metal surfaces to enhance the paint's durability and adhesion. After priming, the aluminum strips can be painted with a suitable paint, such as a high-quality acrylic or enamel paint, following the manufacturer's instructions for application and drying times.</p>

- Q: Does aluminum maintain its properties and resist damage from fire?

- <p>Aluminum strips are relatively fire-resistant, but not completely immune to damage. Aluminum has a high melting point of approximately 660掳C (1220掳F), which means it can withstand high temperatures without melting. However, it can still oxidize and corrode at elevated temperatures, leading to a loss of structural integrity over time. While it may not catch fire, it can still be affected by prolonged exposure to fire, and its performance can degrade depending on the specific conditions and the protective measures in place.</p>

- Q: Explain the environmental effects of utilizing recycled aluminum.

- <p>The use of recycled aluminum has a significant positive impact on the environment. It reduces the need for mining bauxite, which is the primary source of aluminum, thereby decreasing deforestation and habitat destruction. Recycling aluminum also conserves energy, as it requires only 5% of the energy needed to produce aluminum from raw materials. This energy conservation leads to reduced greenhouse gas emissions, contributing to the fight against climate change. Additionally, recycling aluminum reduces the amount of waste sent to landfills, lessening the environmental burden of waste disposal. Overall, the use of recycled aluminum promotes sustainability and helps protect natural resources.</p>

Send your message to us

Mill Finished Aluminum Profiles for LED Strips 8xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords