Jeep Kl Cherokee Aluminum Coil Spacers - Aluminium Prepainted Coil with PVDF/PE 3XXX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX:

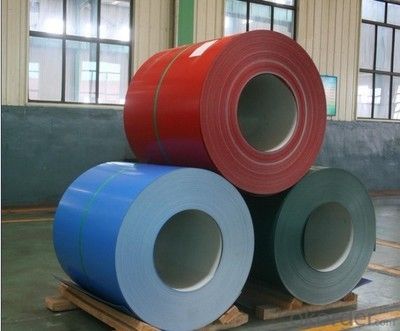

ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX:

High intensity.

Low welding costs.

Outstanding color compatibility after anodizing

Easy to operate. All-position welding.

Excellent corrosion resistance.

Images of ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX:

ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX Specifications:

| Alloy | 1050 1060 1100 3003 3004 3005 3014 3105 3A21 5A02 5005 5052 5083 5251 6061 6063 etc |

| Temper | F O H12 H22 H14 H24 H16 H26 H18 H32 H34 H38 H111 H1112 H116 H321 T5 T6 etc |

| Thickness | 0.02mm - 1.2mm |

| Width | Standard width: 1200mm 1240mm ; Special width:1300mm 1520mm 1570mm 1595mm |

| Diameter | Standar dia: 1200mm ; Interior dia: 150mm 405mm 505mm |

| Weight | 1 T / coil -- 3 T / coil |

| Coating | PE PVDF ACRYLIC |

| Surface | Coated , Mill Finish ,Embossed |

| Color | Ral Color |

| Gloss | 10-90%(EN ISO-2813:1994) |

| Coating Thickness | PE: more than 18 micron PVDF : more than 25 micron |

Coating Hardness (pencilresistance) | More than 2 h |

| Coating Adhesion | 5J (EN ISO - 2409 : 1994 ) |

| Impact Resistance | No peeling or cracking (50kg / cm ,ASTMD - 2794 : 1993 ) |

| Flexibility(T-bend) | 2 T |

| MEK resistance | More than 100 |

| MOQ | 2 T |

| Payment Terms | TT or LC at sight |

| Applycation | Mainly in construction, decoration ,PCB materials, labels, house hold appliance ,lift, cover material ,LCD back panel, refrigeration, air conditioner ,automobile etc |

FAQ:

a: Where is your factory:

Henan Provence.

b:Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect

- Q: This question asks for methods to assess the quality of aluminum coil, which is important in industries where aluminum products are used.

- <p>To check the quality of aluminum coil, you should inspect its surface for any defects like scratches, dents, or discoloration. Measure its thickness and width to ensure they meet the specified standards. Test its mechanical properties, such as tensile strength and elongation, to verify its strength and flexibility. Conduct a chemical analysis to confirm the alloy composition and purity. Check for any impurities or inclusions that could affect performance. Finally, assess the coil's flatness and straightness to ensure it's suitable for further processing.</p>

- Q: What is the typical heat transfer coefficient for aluminum coils?

- The typical heat transfer coefficient for aluminum coils depends on various factors such as the specific application, geometry of the coil, and the surrounding conditions. However, in general, aluminum has a relatively high thermal conductivity, making it an efficient conductor of heat. For forced convection applications, where a fluid such as air or water is used to transfer heat, the heat transfer coefficient for aluminum coils can range from 10 to 100 W/m^2K. This range is influenced by factors such as the flow rate, velocity, and temperature difference between the coil and the fluid. In natural convection scenarios, where heat transfer occurs due to the buoyancy-driven flow of air, the heat transfer coefficient for aluminum coils is typically lower, ranging from 5 to 25 W/m^2K. This lower coefficient is due to the slower movement of air and the reduced heat transfer effectiveness compared to forced convection. It is important to note that these values are general guidelines and can vary significantly depending on specific design considerations, material properties, and operating conditions. Therefore, it is recommended to consult specific heat transfer data or conduct detailed experiments or simulations to determine the precise heat transfer coefficient for a given aluminum coil application.

- Q: Are parakeets allergic to aluminum because I wanted to use a metal pie pan for a bird bath.

- ask a nice bird vet

- Q: How do aluminum coils compare to magnesium coils in terms of strength?

- Aluminum coils are generally stronger than magnesium coils in terms of strength.

- Q: Can aluminum coils be utilized as materials for constructing roofs?

- <p>Yes, aluminum coils can be used for roofing materials. They are known for their durability, corrosion resistance, and lightweight properties, making them an excellent choice for roofing. Aluminum's reflective surface also helps in energy efficiency by reflecting sunlight and reducing heat absorption. It's recyclable and has a long lifespan, which contributes to its sustainability. However, it's important to ensure that the aluminum coils are of the appropriate gauge and quality for the specific roofing application to guarantee structural integrity and performance.</p>

- Q: I'm 14 an was told that aluminum free deodorant would stop yellow stains on my white shirts, so which female deodorant would help stop yellow stains

- Deodorant with aluminum also causes breast cancer. I use Toms of Maine deodorant, which is aluminum-free.

- Q: Can aluminum coils be used in high-humidity environments?

- Indeed, high-humidity environments can accommodate the use of aluminum coils. Due to its corrosion-resistant nature, aluminum proves to be a fitting material for areas with elevated humidity levels. The formation of a natural oxide layer on the aluminum surface acts as a safeguard against moisture, effectively warding off rust and corrosion. Hence, aluminum coils are widely favored for HVAC systems, as they encounter regular exposure to moisture and humidity. Moreover, the lightweight, durable, and exceptional heat transfer properties of aluminum coils render them an optimum selection for a multitude of industrial and commercial applications in high-humidity settings.

- Q: Are aluminum coils suitable for decorative purposes?

- Yes, aluminum coils are suitable for decorative purposes. Aluminum is a versatile material that can be easily molded into various shapes and sizes, making it suitable for decorative applications. Its lightweight nature, durability, and resistance to corrosion make it an ideal choice for both indoor and outdoor decorative projects. Additionally, aluminum can be finished with different coatings and finishes, such as powder coating or anodizing, to enhance its aesthetic appeal. These coatings can provide a wide range of colors, textures, and patterns, allowing for endless design possibilities. Furthermore, aluminum coils can be easily formed into intricate designs, making them suitable for decorative elements like trims, accents, panels, or even sculptures. Overall, aluminum coils offer a cost-effective, durable, and aesthetically pleasing option for various decorative purposes.

- Q: The user is asking if it's safe to use aluminum coil for food preparation in a microwave oven.

- <p>No, you should not use aluminum coil for food preparation in a microwave oven. Aluminum is a metal and can cause sparks or even a fire when exposed to the microwave's electromagnetic field. It can also reflect microwaves, potentially damaging the oven. Always use microwave-safe materials such as glass, ceramic, or microwave-safe plastic containers for food preparation in a microwave.</p>

- Q: Explain the differences between aluminum coils and iron coils, including their properties and applications.

- <p>Aluminum coils and iron coils differ in material composition, weight, strength, and applications. Aluminum coils are made of aluminum, a lightweight, corrosion-resistant metal, while iron coils are made from iron, which is heavier and more prone to rust. Aluminum coils have a lower density, making them ideal for applications where weight is a concern, such as in construction or automotive industries. They also have excellent electrical and thermal conductivity. Iron coils, on the other hand, are stronger and more durable, making them suitable for heavy-duty applications like construction reinforcement and machinery parts. Iron is also magnetic, which is an advantage in certain applications. However, iron is more susceptible to corrosion and requires protective coatings or treatments to extend its lifespan.</p>

Send your message to us

Jeep Kl Cherokee Aluminum Coil Spacers - Aluminium Prepainted Coil with PVDF/PE 3XXX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords