Outdoor PVDF Color Coated Aluminum Framing Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Colored aluminum coil, coating the color on the surface of the aluminum coil. There are 2 kind of paint

PE and PVDF, and are mainly used for aluminum composite panel, aluminum ceiling and aluminum roofing sheet etc. Good decorative ability make it more and more popular in all kinds of industries.

l Specifications of PVDF color coated aluminum coil used outdoors

1.Durable

2.easy processing

3.antirust and antiseptic

PVDF color coated aluminum coil used outdoors

1.Good quality with competitive price

2.Short delivery time

3.Easy processing

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received original L/C or advanc payment

l Company Profile

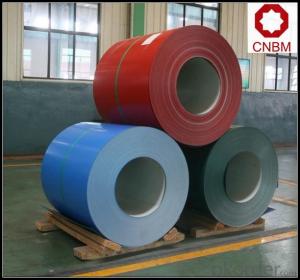

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Color Coated Aluminum Coil is a popular product supplied by CNBM. And we are ready to meet any of your requirements.

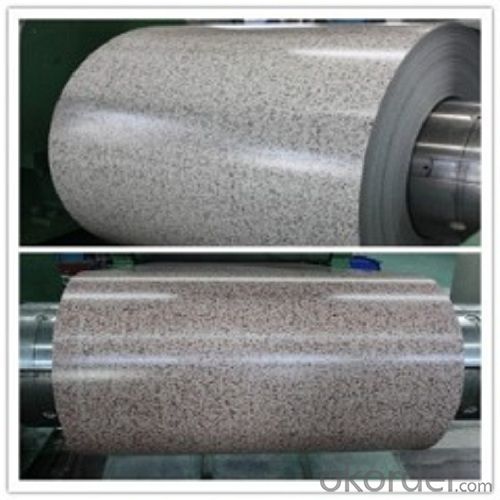

l Product Images

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact us

Email:service@okorder.com

- Q: What are some common types of aluminum coils used in various industrial applications?

- <p>Yes, there are several types of aluminum coils commonly used in industry. These include: 1) Plain aluminum coils, which are used in packaging and construction. 2) Embossed aluminum coils, utilized for decorative purposes and in the automotive industry. 3) Painted aluminum coils, often used in building materials and appliances. 4) Galvanized aluminum coils, which are corrosion-resistant and used in exterior applications. 5) Heat-treated aluminum coils, known for their strength and used in aerospace and automotive parts. Each type serves specific purposes based on the properties of the aluminum and the coatings or treatments applied.</p>

- Q: Can aluminum coils be used for packaging applications?

- Yes, aluminum coils can be used for packaging applications. Aluminum is a lightweight and durable material that is commonly used in various packaging applications due to its excellent barrier properties, resistance to corrosion, and ability to be easily formed into different shapes. It is commonly used for packaging food and beverages, pharmaceutical products, and many other consumer goods.

- Q: What are the common transportation methods for aluminum coils?

- The common transportation methods for aluminum coils include trucking, rail, and shipping. Trucking is often used for short distances or when there is a need for prompt delivery. Aluminum coils are typically loaded onto flatbed trailers or specialized coil trailers equipped with cradles or coil racks to secure them in place during transit. This method offers flexibility and allows for easy access to various locations. Rail transportation is commonly used for long-distance shipments. Aluminum coils are loaded onto railcars, which are specifically designed to accommodate the weight and dimensions of the coils. Rail transportation is advantageous for its cost-effectiveness and ability to transport large quantities of coils in a single shipment. Shipping by sea is another common method for transporting aluminum coils, especially for international shipments. Coils are typically loaded onto cargo ships in specialized containers or directly onto the ship's deck. Shipping offers the advantage of carrying large volumes of coils over long distances, and it is often the preferred method for global distribution due to its efficiency and cost-effectiveness. Overall, the transportation methods for aluminum coils depend on factors such as distance, urgency, quantity, and destination. Companies must consider these factors to determine the most suitable transportation method for their specific needs.

- Q: Can aluminum coils be used for architectural facades?

- Yes, aluminum coils can be used for architectural facades. Aluminum is a popular choice for architectural facades due to its lightweight nature, durability, and versatility. Aluminum coils can be easily formed into various shapes and sizes to create innovative and visually appealing facades. The material is resistant to corrosion, making it suitable for outdoor applications. Additionally, aluminum can be easily coated or finished to enhance its aesthetic appeal and protect it from environmental elements. Overall, aluminum coils offer a cost-effective and sustainable solution for architectural facades.

- Q: A magnet will not attract a aluminum bar, but if you have an electromagnetic field made by an transformer it will interact.Why is that?Why iron is attracted and wood is not?

- Aluminum is not a magnetic material and will not be affected by stationary magnets. However, if a changing magnetic field is present, an electrical voltage will be induced in the aluminum ring and an electric current will flow as a result. This current will produce a magnetic field which will interact with the externally produced magnetic field. The key here is a changing magnetic field - because the voltage induced in the aluminum ring will be proportional to the rate of change of the field. If an aluminum disk is passed between the poles of a powerful magnet, eddy currents will be induced in the aluminum producing a magnetic field that will tend to retard the motion of the aluminum relative to the magnet. The changing field in this case is due to the motion of the aluminum. Iron is attracted to a magnetic field because it is a ferro-magnetic material. Wood is not a magnetic material, and it is not an electrical conductor, so it will not behave as aluminum does in a magnetic field.

- Q: Explain how aluminum coils are connected to electronics.

- <p>Aluminum coils play a significant role in the electronics industry due to their high electrical conductivity and low density. They are used in various components such as transformers, inductors, and chokes, where they help in the conversion and regulation of electrical energy. Aluminum's non-magnetic properties make it ideal for parts that need to be shielded from magnetic fields. Additionally, aluminum coils are used in heat sinks to dissipate heat generated by electronic devices, ensuring their efficient operation and longevity.</p>

- Q: How do aluminum coils contribute to energy-efficient HVAC systems?

- Aluminum coils contribute to energy-efficient HVAC systems by their superior heat transfer capabilities. The high thermal conductivity of aluminum allows for efficient heat exchange, enabling the HVAC system to cool or heat the air more effectively. Additionally, aluminum coils are lightweight and corrosion-resistant, which increases the system's durability and reduces maintenance costs. Overall, using aluminum coils in HVAC systems helps optimize energy usage and improve overall efficiency.

- Q: Hi,I am fairly new to design and have been doing technical drawing for only a few months. We have an item, that supports up to about 800KG of weight, as a C shaped channel. We are currently making this out of 3mm Mild Steel. Due to a new design, we are changing this design to avoid welding and painting the above part. This means we will be making the part from Galv sheet.I would like to make the part from Aluminium because 1) There will be no rust, 2) I think it will look better than Galv sheet but I need to keep the cost down.We use 3mm mild at the moment, because it is easier to weld than 2mm, not for strength really.Therefore, my question is, in everybody's opinion, would it be OK to make it from 2mm Aluminium, or is this likly to end in disaster?FYI, the part is 1600mm long, then on each long side there are presses of up 250mm, down 80mm and down 20mm. The weight is supported at 4 points on the 80mm flanges.What a question for my first go Answers! TIA

- That is actually a complicated question that may need serious engineering. First of all, pure aluminum is rather soft and flexible and you may need to consider an aluminum alloy, perhaps an alloy used in aircraft structures to resists loads. The nature of the load (concentrated or distributed) may affect how the channel tends to bend and the strength needed to resist bending. C channels many tend to bend, shear, twist or buckle and could also fail where loads are applied or at end connections. Likely, mechanical engineers would make a freebody diagram of the channel and study its loading and physical restraints to calculate the strengths needed. Then it is likely a safety factor (10%, 50%, etc. extra strength) would be required depending upon the consequences of failure. If public safety is at issue, calculations should be performed (or checked) by a licensed professional engineer. Because channels (usually) can not be custom made at rolling mills (unless there is a huge order) the next larger available channel in the correct alluminum alloy may be required. Often insurance and product liability demand a correct solution. If the existing mild steel flange works, it (or an assembly drawing) could be presented to show the necessary configuration and help identify possible interferences if channel dimensions must change. Depending upon environment (wet, dry etc.) mixing metal parts may raise corosion concerns. For example, drainage from copper flashings on roofs tends to corode aluminum gutters. Aluminum alloy will likely be more expensive than mild steel and titanium would be stronger and lighter than aluminum (and is now being used in aircrafts) but would be even more expensive. Channel cost may be more important in a large production run than in a one of a kind structure.

- Q: Can aluminum coils be used in electrical cables?

- Yes, aluminum coils can be used in electrical cables. Aluminum is commonly used as a conductor in high-voltage power transmission cables due to its lighter weight and lower cost compared to copper. However, it is important to note that aluminum has higher resistivity than copper, so larger cross-sectional areas are required to achieve the same level of conductivity. Additionally, special connectors and jointing techniques are necessary to account for the differences in thermal expansion and electrical conductivity between aluminum and other materials used in electrical systems.

- Q: Are aluminum coils suitable for high-pressure applications?

- Aluminum coils are generally not suitable for high-pressure applications. While aluminum is a lightweight and corrosion-resistant material, it has relatively low strength compared to other metals such as steel or copper. This lack of strength makes aluminum coils prone to deformation or failure under high pressure. In high-pressure applications, where the system experiences significant stress and requires robust materials, it is more common to use materials like copper or stainless steel, which have higher strength and can better withstand the pressure. However, it is essential to consult industry standards, guidelines, and specific requirements to determine the most appropriate material for a given high-pressure application.

Send your message to us

Outdoor PVDF Color Coated Aluminum Framing Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords