Pre-painted Galvanized Steel Coil for Better Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

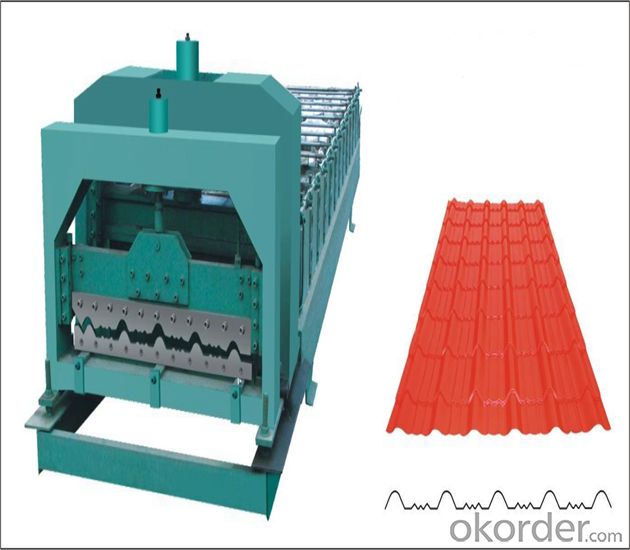

1.Structure of steel tile roll forming machine:

Steel tile roll forming machine consists of feeding, forming, after forming cutting production of color plate smooth appearance beautiful appearances, uniform lacquer veins, high strength, durable, widely used in industrial and civil buildings, such as workshop, warehouse, gymnasium, exhibition halls, theaters and other surface and wall.

2.Main Features of the steel tile roll forming machine:

The tile roll forming machine has the advantages of good corrosion resistance, colorful, beautiful appearance, convenient processing molding and the advantages of the the original strength of the steel plate and the cost is low.

First generation and second generation "automatic moulding color tile equipment" adopt "swinging cylinder driving sliding table", "swinging cylinder" belong to "moulded caigang watts equipment" is "extremely fragile" in accessories, if the forming speed is too fast, cause a large sliding table shock, buffer vibration easily, cause the tiles have crack, is the first and the second generation "stubborn" in the color tile equipment. So the fastest forming up to 6 pieces per minute.

3.Steel tile roll forming machine Images

4.Steel tile roll forming machine Specification

Steel tile roll forming machine has a lot of parameters to set, by using the text screen or touch screen setting. Parameter setting, which has two kinds of equipment parameters and user setting.

Equipment parameters: single pulse length, impulse, molding, molding time, cutter and so on.

User parameters: the number, length, pitch, the first section, small section, section number, preloading and so on.

Main moter power 5.5KW

Hydraulic station power 4KW

Hydraulic oil pump CB-E310

Sprocket P-25.4

Roller station 13

Yield strength 32MPa

Diameter of principal axis 90MM

Material of roller 45#steel hard chrome plating

Processing speed 10-15m/min

Thickness 0.3-1.2 mm

Installation dimension about(L*W*H) 7.5*1.3*1.5M

Total weight 4.2T

Equipment parts includes:roll forming system, hydraulic system, PLC frequency conversion control system, counter, cutting system,decoiler .

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1). What’s your machine installation & commissioning, training:

1or2 technicians will be dispatched to Buyer’s plant for installation & commissioning. Work period: in 5 days. The expense of round trip tickets, accommodation, safety and interpretation shall be covered by Buyer, additional pay allowance to the technicians.

2). Can you make machine according to my design?

Yes, we have experienced technical team to work out the suitable design for you and confirm with you until you agree.

3). What is the warranty for our machine?

We have one year guarantee, and provide whole life's technical support.

4).Is the machine automatic?

Yes, it can be manual and automatic.

5).what policy for broken parts?

within one year,we offer free parts. If beyond one year,you need to buy by factory cost

- Q: How are steel sheets protected from rust and corrosion?

- Various methods and coatings are utilized to safeguard steel sheets from rust and corrosion. One widely used technique involves the application of a protective layer known as galvanized coating. This entails immersing the steel sheets in a bath of molten zinc, thereby establishing a barrier between the steel and its surroundings. The zinc coating functions as a sacrificial anode, corroding before the steel does. This sacrificial shield effectively prevents the infiltration of rust and corrosion onto the steel surface. An alternative method of protection involves the use of organic coatings, such as paint. These coatings create a physical barrier between the steel and the external environment, effectively shielding the metal from moisture and other corrosive elements. The application of paint can be accomplished through various techniques, including spraying, rolling, or electrostatic deposition. In addition to galvanized coatings and paint, steel sheets can also be protected through the utilization of other coatings like epoxy or polyurethane. These coatings offer enhanced protection against corrosion, particularly in harsh environments or when the steel sheets are exposed to chemicals or abrasive substances. Regular maintenance and inspections play a crucial role in the prevention of rust and corrosion on steel sheets. This involves surface cleaning, the removal of any debris or contaminants, and the repair of any damaged or worn-out coatings. By adhering to these preventive measures, steel sheets can remain shielded and maintain their structural integrity for an extended lifespan.

- Q: Can steel sheets be used for electrical motor laminations?

- No, steel sheets cannot be used for electrical motor laminations. Electrical motor laminations are typically made from a specific type of electrical steel called silicon steel, which has low electrical losses and high magnetic permeability. Steel sheets do not possess these desired properties, making them unsuitable for use in electrical motor laminations.

- Q: Can steel sheets be used for signage purposes?

- Yes, steel sheets can be used for signage purposes. Steel sheets are durable and can withstand harsh weather conditions, making them suitable for outdoor signage. They can be cut, shaped, and welded into various sizes and designs, providing flexibility in creating custom signage. Steel sheets can also be painted or coated with different finishes to enhance aesthetics and ensure longevity. Additionally, steel sheets are sturdy and can be mounted securely, making them ideal for large and heavy signage installations.

- Q: What are the different types of steel sheet finishes for automotive applications?

- Automotive applications commonly utilize various types of steel sheet finishes. These finishes are applied to the surface of the steel sheet for the purpose of enhancing its appearance, durability, and resistance to corrosion. The mill finish, for instance, is a natural finish that the steel sheet attains after undergoing hot or cold rolling. It possesses a dull gray appearance and is typically employed in applications where aesthetics are not of paramount importance. On the other hand, the galvanized finish is a favored choice, whereby a layer of zinc is coated onto the steel sheet to safeguard it against corrosion. This finish exhibits exceptional resistance to corrosion and is frequently utilized in automotive body panels and structural components. Another option is the painted finish, which involves coating the steel sheet with a layer of paint. This finish improves both the aesthetics and corrosion protection of the steel sheet. Painted finishes are available in a variety of colors and textures, offering customization and branding possibilities. Furthermore, specialized finishes, such as the electro-galvanized finish, are also available. This finish involves the application of a thin layer of zinc to the steel sheet through an electroplating process. It provides enhanced corrosion resistance and is commonly employed in automotive parts that necessitate a high level of rust protection. Lastly, the brushed or polished finish entails mechanical polishing of the steel sheet surface to create a smooth and reflective appearance. This finish is often used for decorative purposes in automotive applications, like trim or accents. In conclusion, the range of steel sheet finishes for automotive applications includes mill finish, galvanized finish, painted finish, electro-galvanized finish, and brushed/polished finish. Each finish offers distinct advantages in terms of appearance, durability, and corrosion resistance, enabling manufacturers to select the most suitable option for their specific automotive application.

- Q: How do steel sheets compare to other materials like aluminum or copper?

- Steel sheets have several advantages over other materials like aluminum or copper. First, steel is generally stronger and more durable, making it suitable for a wide range of applications. Additionally, steel has a higher melting point than aluminum, making it better suited for high-temperature environments. Steel sheets are also relatively more affordable and readily available compared to copper, making them a cost-effective choice for many industries. However, it's important to consider specific requirements and characteristics of each material before making a final comparison.

- Q: What are the different surface textures available for steel sheets?

- Some of the different surface textures available for steel sheets include smooth, matte, brushed, polished, embossed, and patterned.

- Q: Are the steel sheets suitable for outdoor applications?

- Yes, steel sheets are suitable for outdoor applications due to their durability, resistance to harsh weather conditions, and ability to withstand corrosion.

- Q: Is the steel plate 1.5 meters wide and 2 meters wide at the same price? .

- For specific quotation, you need to consult the seller of the steel plate, you give him the size you want, and he will calculate the situation after cutting to quote you.

- Q: Can steel sheets be used in furniture applications?

- Yes, steel sheets can be used in furniture applications. Steel sheets are commonly used in the construction of various furniture pieces such as tables, chairs, shelving units, and storage cabinets. They provide strength, durability, and a modern aesthetic to furniture designs. Additionally, steel sheets can be easily formed and shaped into different configurations, making them versatile for various furniture styles and functions.

- Q: Are steel sheets suitable for exterior wall cladding?

- Yes, steel sheets are suitable for exterior wall cladding. Steel is a durable and strong material that offers excellent resistance to weather conditions, including rain, wind, and sunlight. It is also low-maintenance and can be easily customized to achieve various aesthetic designs. Additionally, steel is fire-resistant, making it a safe choice for exterior wall cladding.

Send your message to us

Pre-painted Galvanized Steel Coil for Better Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords