Aluminum Sheets Connecticut - Aluminium Plain Sheets 1100 for Bus Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Plain Sheets 1100 for Bus Body Description:

We can produce aluminum sheet,color aluminum sheet and plastic composite panel base material. They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of Aluminium Plain Sheets 1100 for Bus Body :

Good Corrosion Resistance

No scratches, white corrosion

High Quality

Competitive Price

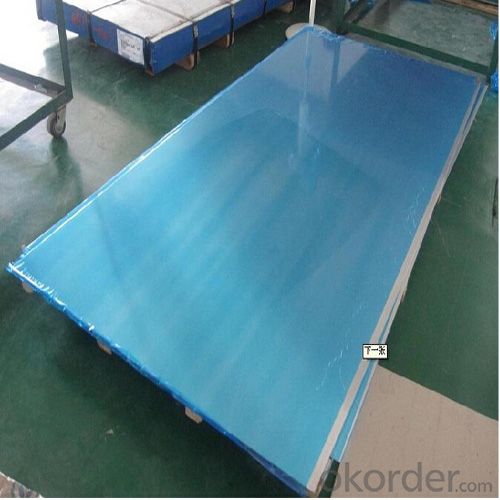

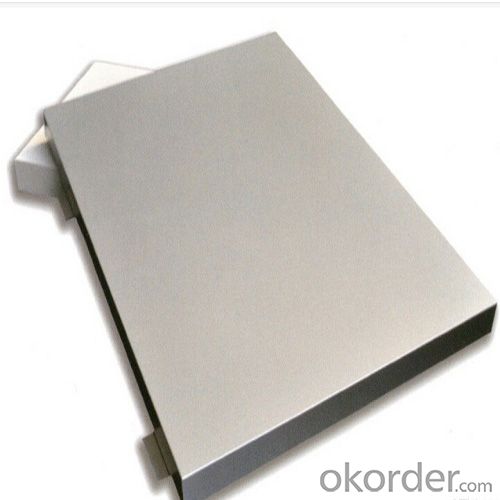

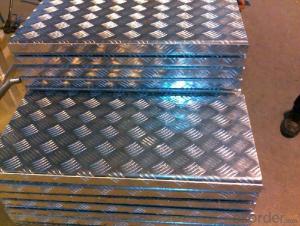

3. Aluminium Plain Sheets 1100 for Bus Body Images:

4. Aluminium Plain Sheets 1100 for Bus Body Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: What are the limitations of using aluminum sheet?

- Using aluminum sheet in various applications comes with several limitations. Firstly, compared to steel or titanium, aluminum is a relatively soft metal. This means it is more prone to scratches, dents, and deformation when subjected to heavy loads or impacts. As a result, it may not be suitable for applications that require high strength or resistance to damage. Secondly, aluminum has lower thermal conductivity than other metals. This can be a disadvantage in applications that require efficient heat transfer, such as heat exchangers or cooling systems. Thirdly, aluminum is susceptible to corrosion. Although it has a natural oxide layer that provides some protection, it can still corrode in certain environments, especially in the presence of moisture or acidic substances. This limits its use in applications where corrosion resistance is crucial, such as in the marine or chemical industries. Additionally, compared to other options, aluminum is a relatively expensive material. Its production and extraction processes require significant energy and resources, which contribute to higher costs. Therefore, it may not be the most cost-effective choice for some applications. Lastly, aluminum has limited compatibility with certain substances. It can react with certain chemicals, leading to degradation or contamination. Therefore, it may not be suitable for applications where it will come into contact with substances that can cause adverse reactions. In conclusion, although aluminum sheet has numerous advantages such as its lightweight nature, good electrical conductivity, and ease of fabrication, it is important to consider its limitations when choosing it for specific applications.

- Q: Can aluminum sheet be used for aerospace structural components?

- Yes, aluminum sheet can be used for aerospace structural components. Aluminum is commonly used in the aerospace industry due to its desirable properties such as low density, high strength-to-weight ratio, and excellent corrosion resistance, making it suitable for various structural applications in aircraft and spacecraft.

- Q: How do you ensure the dimensional accuracy of aluminum sheets?

- To ensure the dimensional accuracy of aluminum sheets, several measures can be taken. First, it is important to use high-quality aluminum material that meets the required specifications and standards. Secondly, employing precision cutting techniques, such as laser cutting or water jet cutting, can help achieve precise dimensions. Additionally, utilizing advanced measurement tools and equipment, such as calipers or coordinate measuring machines, allows for accurate dimensional verification. Implementing a robust quality control process, including regular inspections and monitoring during the production process, can further ensure dimensional accuracy.

- Q: This question asks for a comparison of the positive and negative aspects of utilizing aluminum sheets in various applications.

- <p>Advantages of using aluminum sheets include their lightweight nature, which reduces transportation and handling costs. They are also corrosion-resistant, making them suitable for outdoor applications. Aluminum sheets are recyclable and environmentally friendly, with a high recycled content rate. They are also easy to fabricate and can be cut, bent, and shaped into various forms. Disadvantages include lower strength compared to steel, which may require thicker sheets for certain applications. They can also be more expensive than some other materials, and their light reflection can sometimes be a concern in certain environments.</p>

- Q: Can aluminum sheets be used for balcony railings?

- Yes, aluminum sheets can be used for balcony railings. Aluminum is a popular material for balcony railings due to its lightweight nature, durability, and resistance to corrosion. It is a versatile material that can be easily formed into different shapes and designs, making it suitable for various architectural styles. Additionally, aluminum railings require minimal maintenance and can withstand harsh weather conditions, making them a practical and long-lasting choice for balcony railings.

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of residential buildings?

- <p>Yes, aluminum sheets can be used for exterior walls in residential buildings. They offer several advantages such as durability, resistance to weather and corrosion, and low maintenance. Aluminum is lightweight, which can reduce structural load, and it can be easily shaped and installed. Additionally, it has good thermal performance and can be combined with insulation for energy efficiency. However, it's important to consider the aesthetic appeal, as aluminum may not match the traditional look of some residential buildings, and ensure it meets local building codes and standards.</p>

- Q: what family does aluminum belong to?its NOT the boron or aluminum family.i know its group 13. i need the family name.please help

- Aluminum is an orphan metal- (orphans appear in groups 3, 4, and 5 of the periodic table). They are called orphans simply because none belongs to a clearly defined family (like alkaline earth, transition metals, halogens, etc). Sometimes aluminum and the three elements below it in Group 3—gallium, indium, and thallium—are lumped together as the aluminum family, but that's not a clearly recognized family.

- Q: I am following a recipe for braised ribs that calls for wrapping the ribs in heavy duty aluminum foil. I don't have heavy duty, so can regular aluminum foil be used as a replacement?

- Paleohacks Cookbooks + Primal Sleep : 7ce24fc1fn4o2k6fh7paq8qa2m.hop.cl... 4 Offers: Fat Burning Kitchen, 101 Anti-aging Foods, Truthaboutabs Etc : 1bb8clh1autw9k86xhr9m26x21.hop.cl... Better Breads Guilt-free Desserts: Top Converting Health Offers! : da5acmc7fr4x2nb0r3gqy4vju7.hop.cl...

- Q: This question asks for the common types of aluminum sheet windows and doors that are available in the market.

- <p>Common types of aluminum sheet windows and doors in the market include sliding windows, casement windows, fixed windows, and awning windows. For doors, there are sliding doors, swing doors, folding doors, and automatic doors. Each type has specific features and applications, such as sliding windows being space-saving and easy to operate, while casement windows offer better ventilation. Sliding doors are popular for their smooth operation and minimal space requirement, and swing doors are traditional and widely used for their durability and security. These aluminum products are valued for their strength, durability, and low maintenance requirements.</p>

- Q: How does aluminum sheet perform in extreme temperatures?

- Aluminum sheet performs well in extreme temperatures as it has a high melting point of 660°C (1220°F) and exhibits excellent thermal conductivity. It can withstand both hot and cold temperatures without significant deformation or structural damage, making it suitable for various applications in extreme environments.

Send your message to us

Aluminum Sheets Connecticut - Aluminium Plain Sheets 1100 for Bus Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords